T-5 Killer

Well-Known Member

When the Ford Motor Company re-introduced the fabled 5.0L in 2010 with the new 2011 Mustang GT, the Ford faithful were practically beside themselves to get their hands on one. This wasn’t just a nostalgic return of the “5.0″ namesake, but the unveiling of an engine unlike any other in Ford’s history – one that just might top the original. Capable of producing the power to run in the tens naturally aspirated and structurally sound enough to handle copious amount of boost – this was horsepower nirvana for Mustang fans.

But for the extremists among us, how exactly do you improve upon an already stout piece of machinery? The good folks at Wiseco and K1 Technologies have an answer to that, and in doing so, they’ve brought the likewise well-revered “351″ name back to the Mustang.

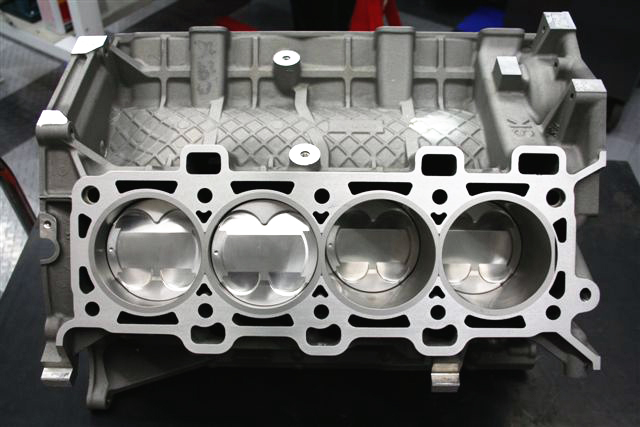

Sister companies Wiseco and K1 plus development partner ERL Performance have joined efforts to produce a stroked and bored 5.0L-based 351 short block, which is expected to handle upwards of 2,000 horsepower and nearly 8,000 RPM on the stock heads. These will almost certainly appeal to the heads-up drag racing and high-end street car market.

During last year’s Performance Racing Industry show down in Orlando, Wiseco pulled the wraps off of their brand new, stroked 5.0L Coyote-based DOHC V8 short block assembly, displacing an increased 351 cubic inches. Needless to say, the Wiseco group was just as excited to show off their new piece as Blue Oval fans were to get a glimpse of it.

In short, this all-new stroker package from Wiseco and its sister brand, K1 Technologies, features K1′s 4340 billet crankshaft and 4340 billet H-beam steel connecting rods, housed within a 95mm sleeved OEM block finished in conjunction with ERL Performance. Several options also exist from within Wiseco’s extensive lineup of high performance pistons to meet the compression ratio needs of one’s particular combination.

The heart of Wiseco’s short block assembly is an OE-based 5.0L Coyote engine block that retains the factory deck height, making it a direct bolt-in replacement for the OEM 5.0L. “That was a big thing – we didn’t want to do something goofy that made it hard for people to install,†ERL Performance’s Sean Ragains said. ERL Performance, a highly regarded engine building and machining corporation, performs the sleeving and boring of the original Coyote block and outfits it with an optional billet main cap option.

ERL, based in Indiana, is among Wiseco and K1′s noted development partners, with the two parties having previously collaborated to build the first 500 cubic inch LS1 on the market in 2005. Said Nutter, “They’re very good at block sleeving – the best in the country I believe. When we develop a new combination, we need to know that it’s not only structurally sound, but that everything is modeled properly to avoid issues. We work closely with ERL and the combination always turns out as a pretty well ‘bolt-together’ package.â€

The 4340 billet H-beam connecting rods from K1 have been designed specifically for this stroker engine combination and are slated to go into production in the coming weeks.

Strength and durability aside, perhaps the most intriguing aspect of the design of this block that Wiseco and ERL have developed is its ability to bolt up directly to every single component found on the factory Coyote engine. This includes the cylinder heads and all – making the swap a simple and more importantly, affordable, process. “This was our absolute goal,†said Nutter. “We wanted this thing to be completely invisible to the user with the exception of the added cubic inches. Everything just bolts right up. The displacement has increased from 5.0 to 5.8 liters, but otherwise, they’d never know it by looking at it.â€

The K1 crankshaft is chiseled from 4340 billet steel and counter-weighted, and the K1 4340 H-beam connecting rods have been designed specifically for this stroker combination. Once in production, the rods are expected to ship with 7/16″ bolts, which is overkill, but the added strength offsets the rather minute weight difference of smaller bolts.

The Wiseco pistons are a dedicated forging made specially for the 5.0L/5.8L and are constructed from 2618 alloy with skirt coatings and use a .200 wall wrist pin. Wiseco has designed the piston for use with camshafts with a lot of lift, boasting very deep valve pockets, allowing for a lot of freedom of movement for tuners to work on the cam facing. Rounding out the package are premium quality heads studs and other hardware from ARP.

ERL Peformance has re-sleeved the factory 5.0L engine blocks and produced a large bore of 96mm, which is considered to be the limit for high-horsepower, boosted combos that are expected to utilize this block.

Upon its release to the market, Wiseco’s stroker short block is expected to garner attention from a wide variety of market segments, ranging from street-driven cars outfitted with centrifugal superchargers making 800-plus horses with ease, to naturally aspirated road racing applications, to the extreme blown and turbocharged drag racers producing well in excess of 1,000 horsepower and more in the neighborhood of 2,000.

“In terms of market acceptance, racers that have been around the block – real engine builders – are going to take a look at the combination and say ‘that stroke, that rod length, that piston’ and they’ll recognize that it’s a good combination in terms of its ability to hold up to big horsepower,†says Nutter. “And once the average guy out on the street with a supercharger sees the racers running it successfully, they’ll be convinced that it’ll serve them well for a long, long time on the street.â€

Wiseco is still several months from releasing their new gem of a short block into the wild, thus concrete reviews and horsepower figures aren’t available at this time. Like any engine though, the puzzle of valvetrain, power adder, and other components is going to determine what this thing can ultimately produce.

Proclaimed Nutter, “The larger displacement of this engine is going to do two things: first, it’s going to soak up really large camshafts, and so it’ll allow something that was a fairly radical cam with the 5.0L that idles kind of rough to idle smoothly and make it possible to run a larger cam and create more power. It’s also going to lower the operating range. We don’t expect there to be any problem turning this thing 8,500 RPM; it’s just not a big deal with this stroke and piston speed. It’s really going to take advantage of the excellent cylinder heads.â€

This 3D model illustrates the 4340 billet, core-hardened, and nitrited crankshaft that K1 has developed and will soon put into production.

With the larger bore and shorter stroke capability of these engines allowing for unheard of RPM ranges, Nutter believes this combination will run roughshod over the competition in road racing venues. States Nutter, “With these guys reaming these things to 7,800 RPM on stock heads, this thing is just going to dominate. Think about what our GM stuff has to do to handle 7,800 RPM; and this thing is doing it with stock heads.â€

While the advantages of Wiseco’s new short block assembly are plentiful, like anything, there’s always bad news to go with the good. The bad news in this case, however, isn’t of Wiseco’s doing, but simply the constraints of the original Coyote engine design. “We’re pretty well at the end of the road with it. When we model these combinations, we take the engine right up to the very limit and then we call it a day, and on this particular engine, 351 cubic inches is all that we could get out of it and still have a beefy combination,†Nutter says. “For lighter-duty naturally aspirated applications, we could possibly install a long rod in it, but there’s not much more that you’ll be able to do with this engine.â€

Because this short block is based around an original 5.0L Coyote engine block from Ford, every factory component from the intake to the oil pan mates right up to a stronger and more powerful rotating assembly.

Ragains echoed that statement in stating, “A 95mm bore is about the limit, with 96mm a possibility, but you’re talking about naturally aspirated applications only at that point.â€

For those interested in punching their own Coyote block out to 95mm or purchasing one for a new build, ERL is presently equipped to do so. Likewise, the rotating assembly components will be available separately from Wiseco upon their release, but Nutter points out that they must be used with the right sleeve length to make sure the piston is supported at bottom dead center correctly so it doesn’t wear improperly. In essence, you don’t have to buy the short block assembly as it was designed, but you just might want to.

http://www.stangtv.com/tech-stories...in-forces-to-create-bigger-better-351-coyote/

So awesome!

![IMG_20140524_152057360_HDR[1]](/data/xfmg/thumbnail/0/66-1b90088565df25d76ff5bd73b7f47142.jpg?1623783787)