Story goes like this....

About 9 years ago, i was poking at the idea of a 5.4l 4v using the B series heads. Those early days for me took a turn involving alot of life struggles and i had to put the project on hold and move forward with a more feasible project like 18.1static compression 2v...lol.

B 4v heads were used in the 96-98 cobras, also lincolns from the modulars inception back in 91. I believe they showed up in '92 fwd continentals iirc. B series heads are the first 4v heads produced for modulars and are very plentiful. Most consider them boat anchors ....mostly due to availability of intake manifolds. All there were was lincoln mark8 and front wheel drive manifolds that stopped breathing early and 96-98 cobra intakes that breath very well, but also suffer from low flowing, drivable torque flow. You guy know the history! Do i really need to explain it?

Anyhow, ....a certain someone....not naming any names (lwarrior) OOPS!

Like he always does, he has rattled whats rolling around in my head and its created alot of noise that i just cant ignore!

Solution? Give in to it! Surrender! So....after much debate with myself(that eventually lead to a nice self loving shower) ive decided to open up the 5.4l 4v files that consists of B heads!

Whats in store?

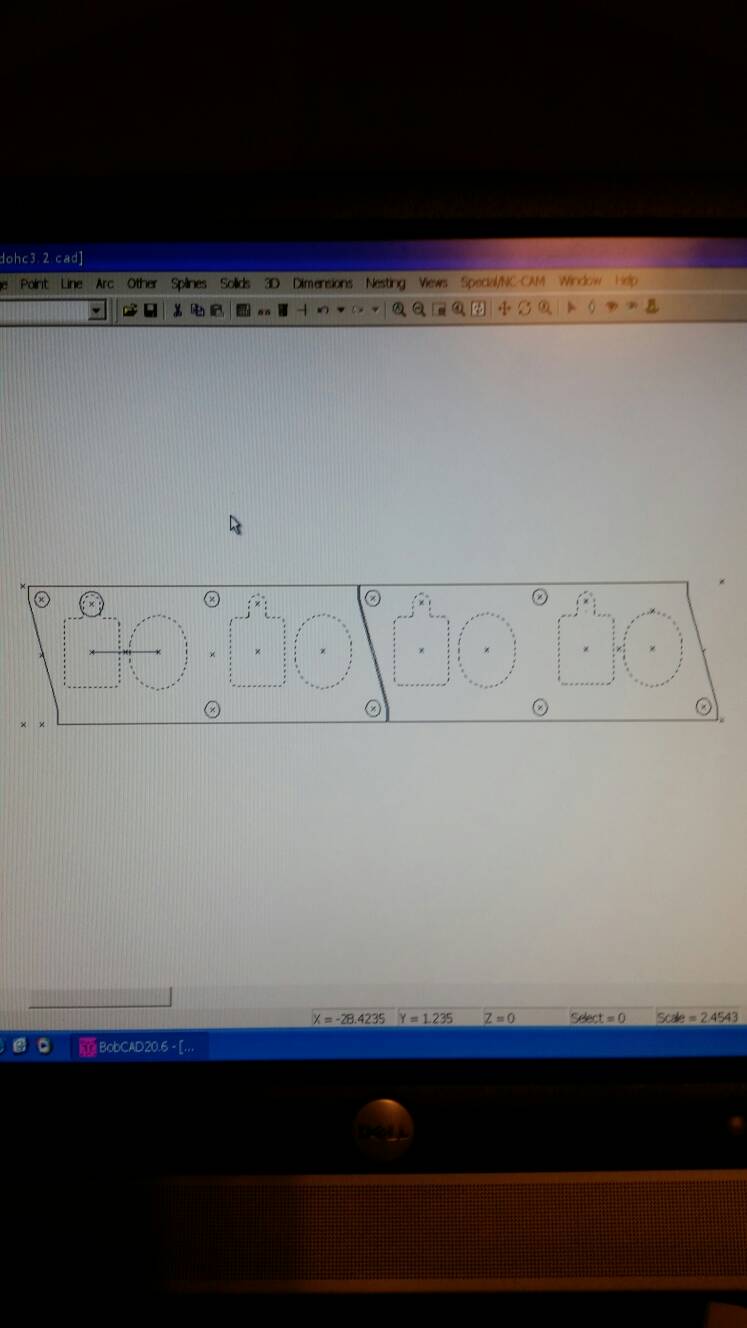

Im glad you asked! This thread will continue on with suggested info by the talented folk of sn95forums (YOU) that will help me in the creation of a solid performing intake manifold to be used on a 5.4l engine using B series 4v heads.

Sent from my SM-G900P using Tapatalk

About 9 years ago, i was poking at the idea of a 5.4l 4v using the B series heads. Those early days for me took a turn involving alot of life struggles and i had to put the project on hold and move forward with a more feasible project like 18.1static compression 2v...lol.

B 4v heads were used in the 96-98 cobras, also lincolns from the modulars inception back in 91. I believe they showed up in '92 fwd continentals iirc. B series heads are the first 4v heads produced for modulars and are very plentiful. Most consider them boat anchors ....mostly due to availability of intake manifolds. All there were was lincoln mark8 and front wheel drive manifolds that stopped breathing early and 96-98 cobra intakes that breath very well, but also suffer from low flowing, drivable torque flow. You guy know the history! Do i really need to explain it?

Anyhow, ....a certain someone....not naming any names (lwarrior) OOPS!

Like he always does, he has rattled whats rolling around in my head and its created alot of noise that i just cant ignore!

Solution? Give in to it! Surrender! So....after much debate with myself(that eventually lead to a nice self loving shower) ive decided to open up the 5.4l 4v files that consists of B heads!

Whats in store?

Im glad you asked! This thread will continue on with suggested info by the talented folk of sn95forums (YOU) that will help me in the creation of a solid performing intake manifold to be used on a 5.4l engine using B series 4v heads.

Sent from my SM-G900P using Tapatalk