Alright everyone! Time for an update! But first, a tiny bit of carnage lol. I tried smashing the back of the spindles to pop the ball joints out, but they just wouldnt budge. So I bought a "press" to pop the ball joints out.

The fork goes under the spindle, around the ball joint and the "hook" or clamp goes on top of the ball joint stud. Well, it wouldnt open far enough so i had to shave the back of the tool to allow it to open more

to much pressure

But i went and rented one from autozone and tada!!

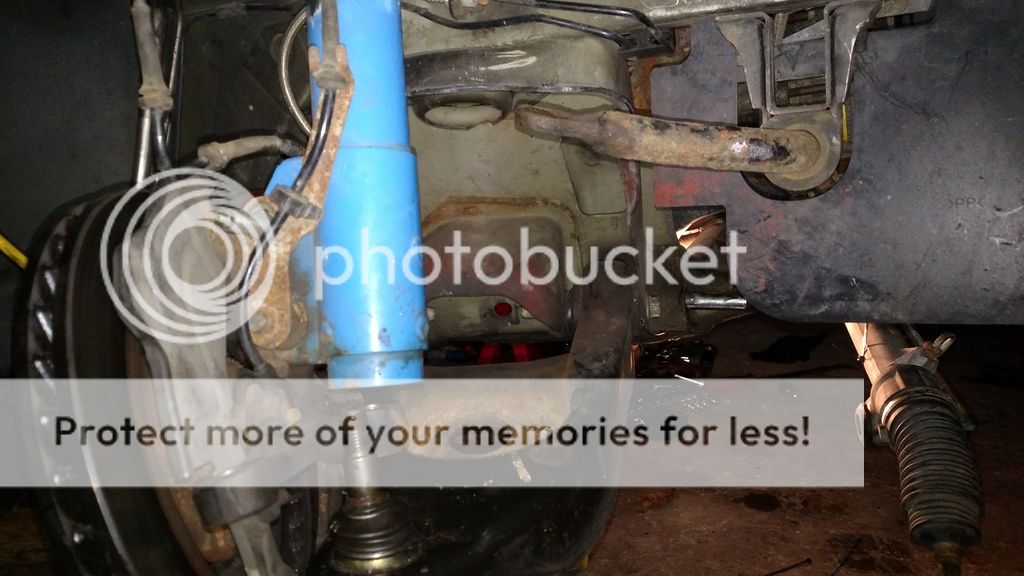

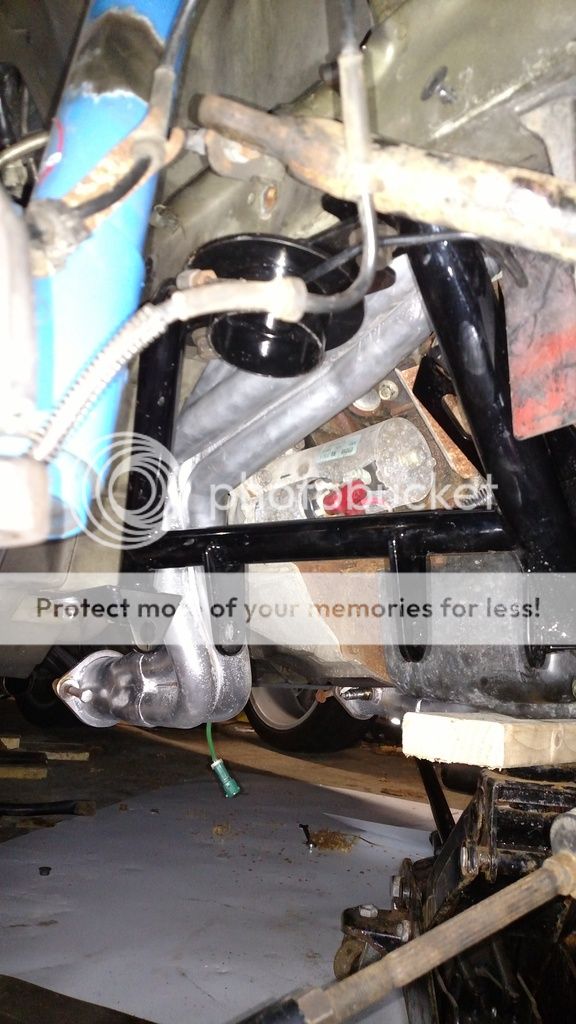

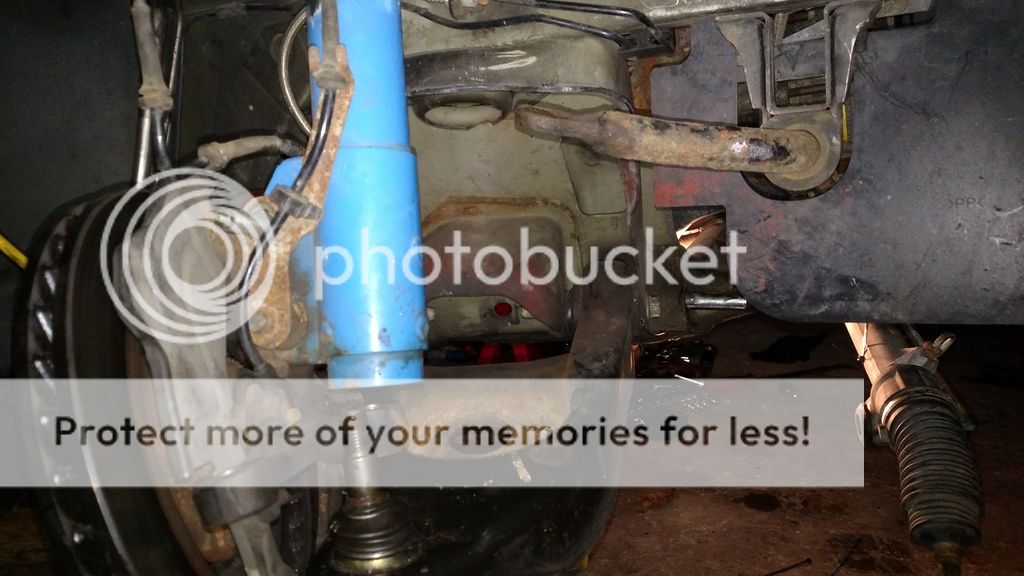

Finally had a friend stop by and lend a hand in ripping the old k member out, and luck for me he brought his electric impact gun. K member came out pretty smoothly.

But this came up short lol. We finally removed the old exhaust out and didnt break any of the bolts which was awesome! But the manifold to midpipe bolts were a pain in the aarse. and the driverside 02 sensors broke so i had to buy two new sensors. We pretty much have the passenger side long tube in the car, but the driver side was proving to be a pain. the oil dipstick wouldnt come out... easy. finally got it out with the motor mount removed. the oil tube came out. and them had to install the exhaust studs.

Well the 3rd cylinder on the driver side.... the pipe for that cylinder i guess is known problem with manifold studs. so i am having my buddy trim the stud a bit and should have it tomorrow.

As you can see on the middle pipe it was digging into the header and prevented the header from sitting flush. Well this haulted the whole day. couldnt install the k member, couldnt install motor mounts and couldnt install the oil dip stick tube.

So tomorrow should have the bolts broken loose from the stock k member, and swap the control arms over, should have the header inplace, and k member installed. then the small tiny stuff after that.

yay mustang stuff