Hello, im a newbie posting here.. it has questions too, so i don't know i this thread goes here, but nobody is perferct O0 im bullitt66 form svtperformance and this is my first post lol..

I didn't found a lot of info for the t-45, but my trans broke someting, i was able to put the shifter in 1rst, and the trans was in 1rst to, changed the shifter to 2nd or neutral and the trans would still be in 1rs, So i took out the trans from the car myself and opened it with my friends, i found it was the gear shift plate that broke, what was the reason? :shrug: someone here may know i hope, now im looking to upgrade it because i already disassembled it all, do you guys know if any hanlon kit cames with that shifter plate? maybe red98cobrastang knows..

what kit should i get now so it can build an upgraded t-45 tha i won't have to worry for some time?.. i know ill need steel shift forks, what more would you recomend??

the good thing is i did it myself with my friends and learned as always, here are the pics of the progress..

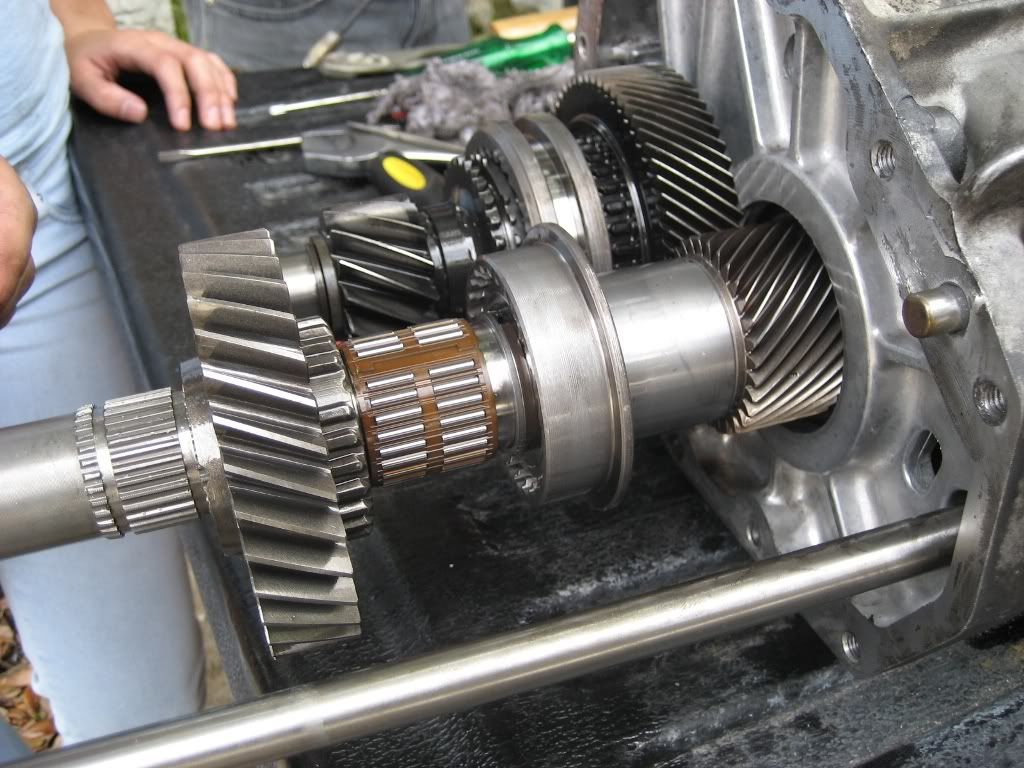

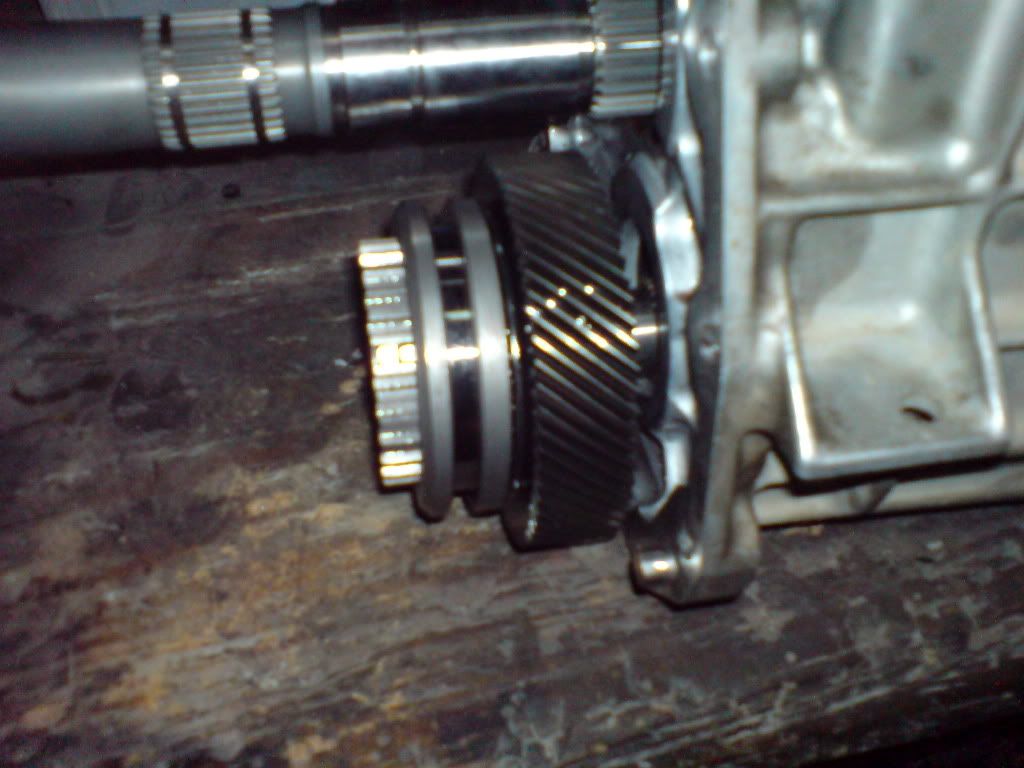

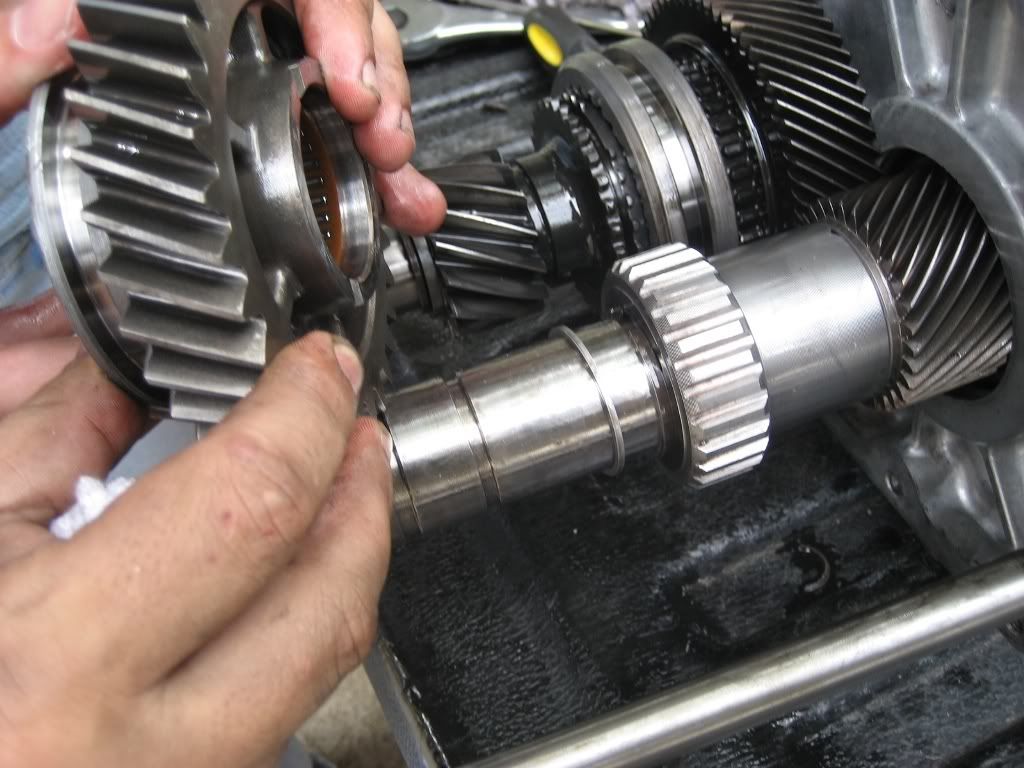

First we took out the bolts of the tailhousing, you'll need to punch a pin that sits where the shifter goes, so you can remove the tailhousing, then it should look like this..

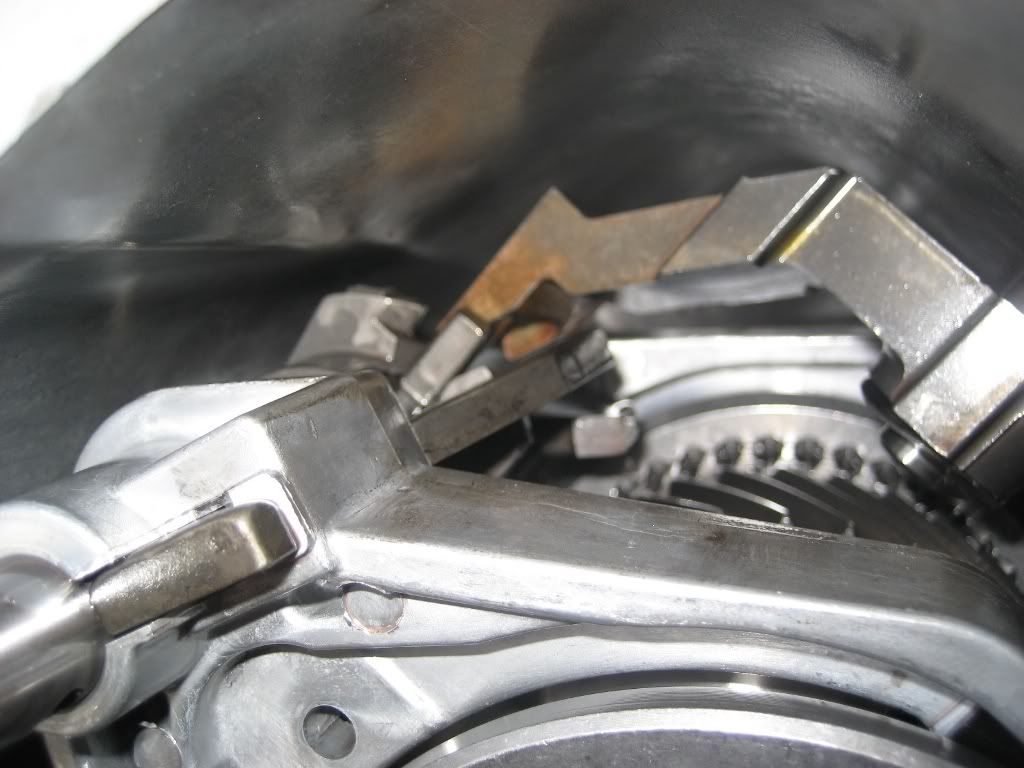

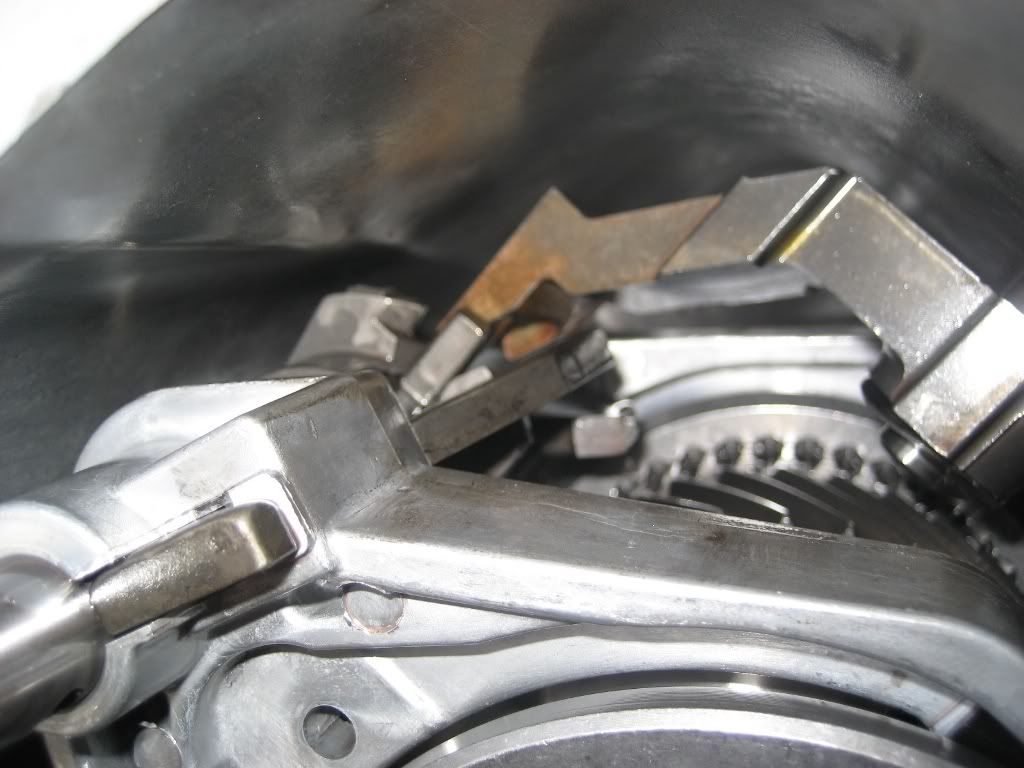

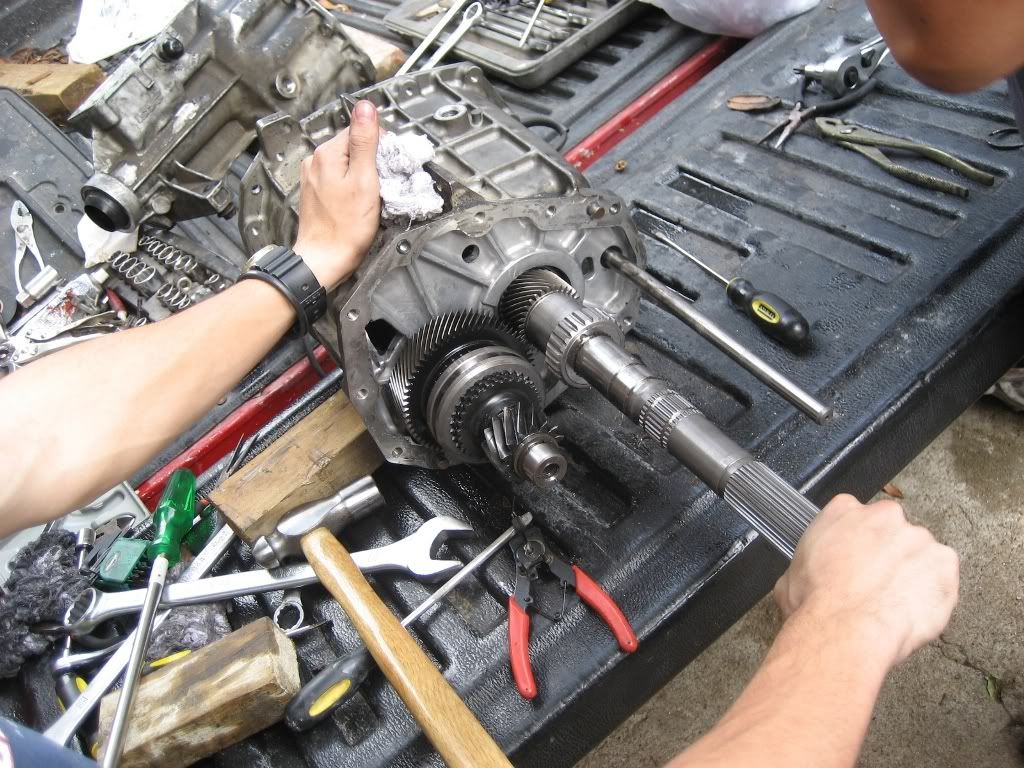

Then remove the bellhousing and you can see the shiter plate broke if you pay attention or if you know the t-45.. i should be like two little "U", but since one broke, thats why i was able to move the shifter, but not the shift forks..

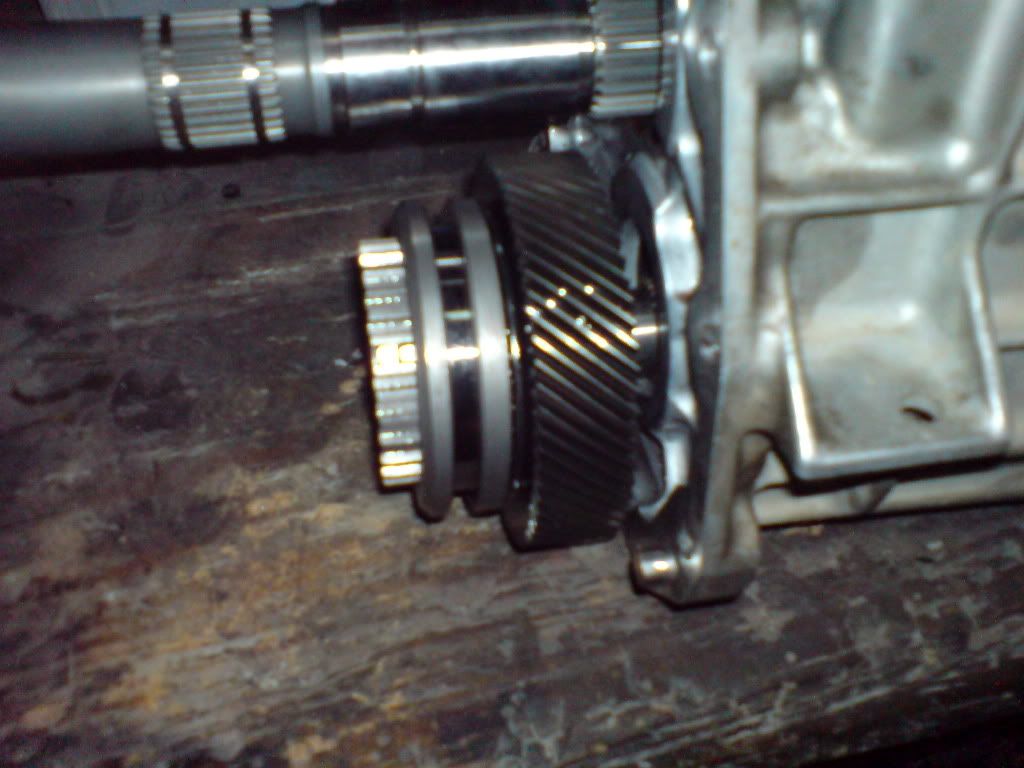

This is the piece that broke, i found someone on stangnet posted that too, but the only reply was "check out d&dmotorsports

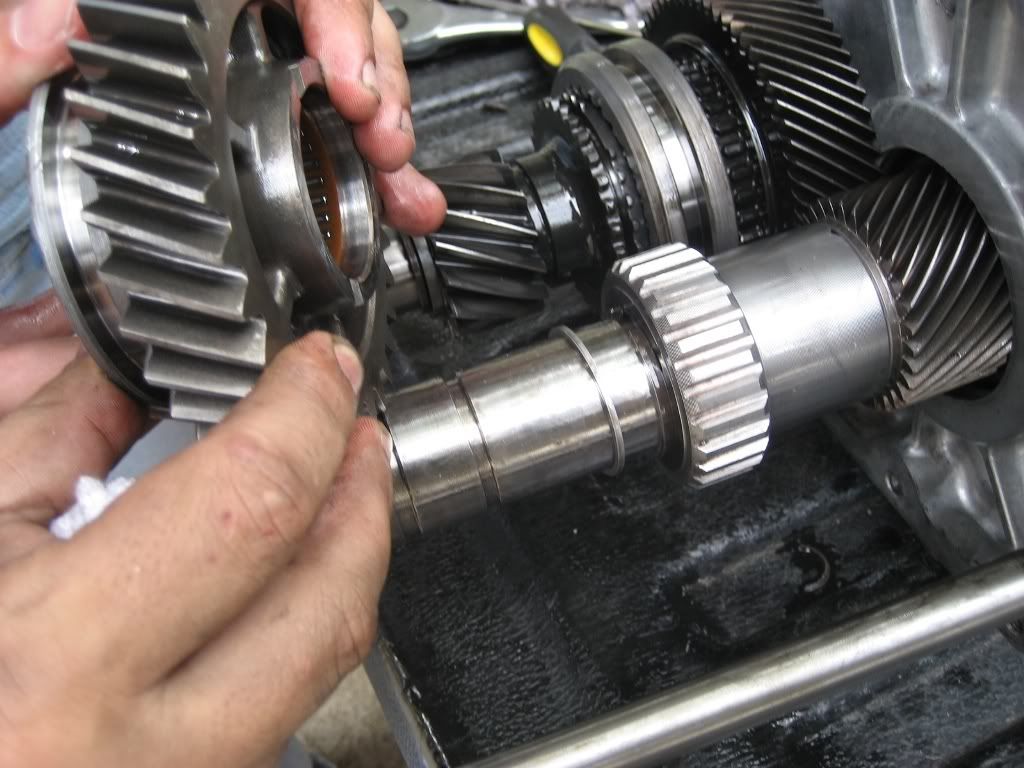

Starting from the back, we took the bushing out, and the c-clips we found on the road

Tought that was the problem, Japan Bearings epper:

epper:

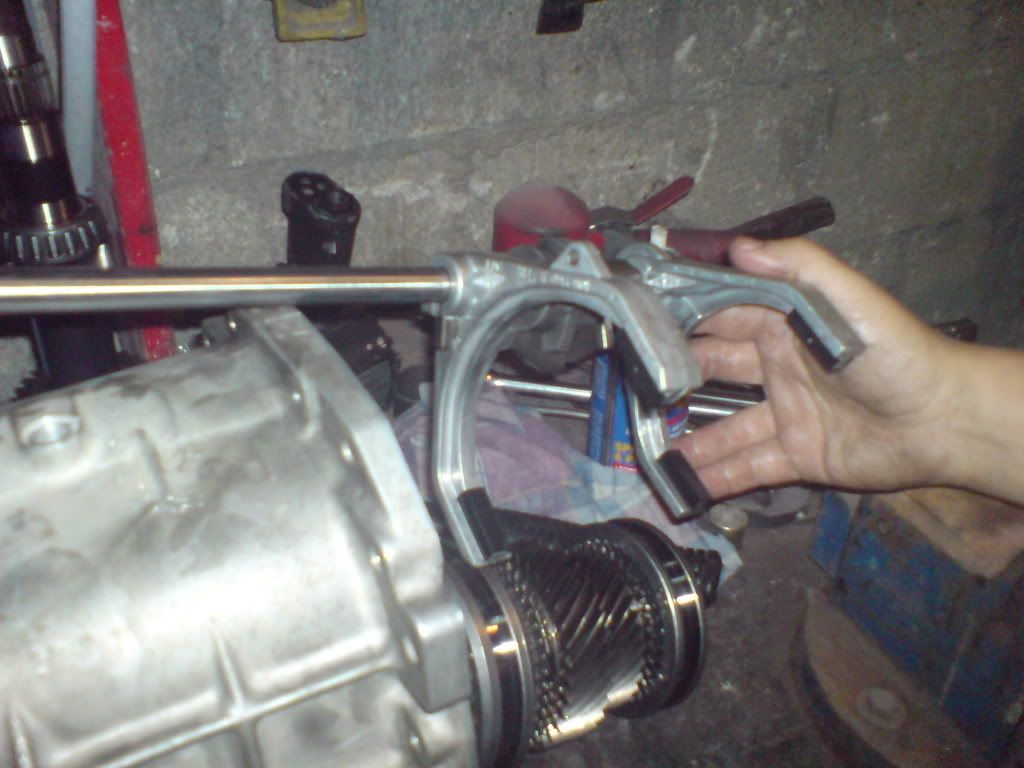

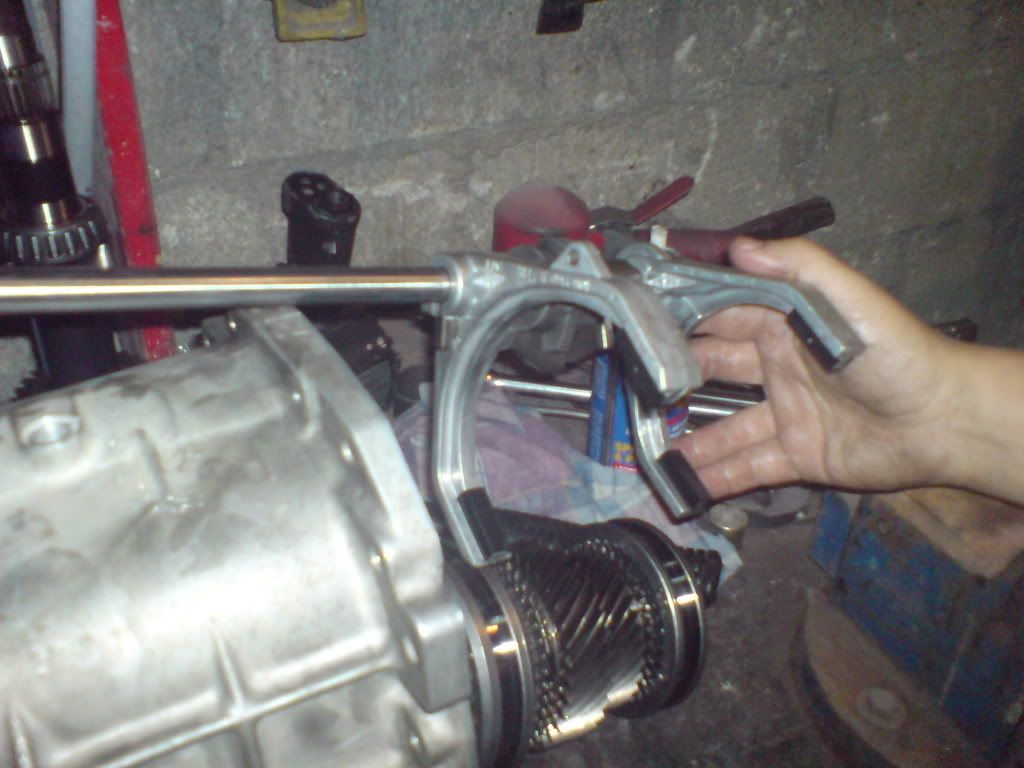

Since we don't have all the tools, we like to improve, those parts were not born there.. lol

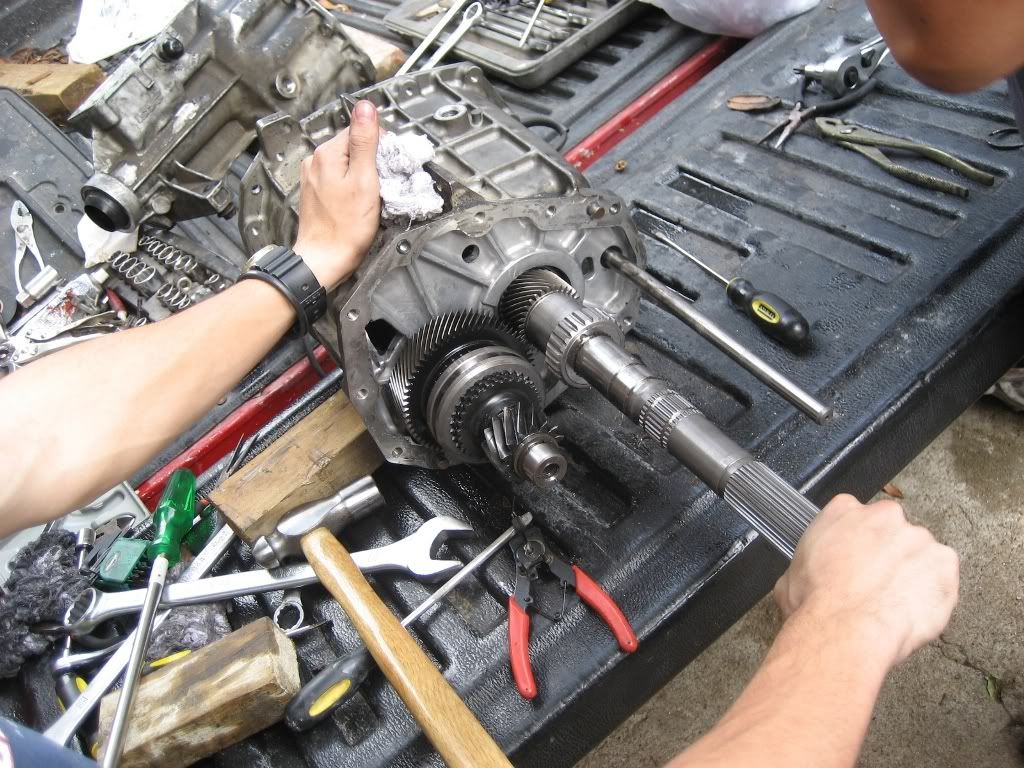

Now, we go to the front..

As always, the last screw was a PITA, aluminum + a steel screw gets real tight as time passes..

We used a torx and we broke it, then we used an air gun, and broke the torx before the screw could move.. it was about 250lb/ft (like 3-4 hondas) and it didn't move. So i learend that if you heat the aluminum, and then use a little wd-40 on the screw, it won't be tight anymore.. it was real cool to see this..

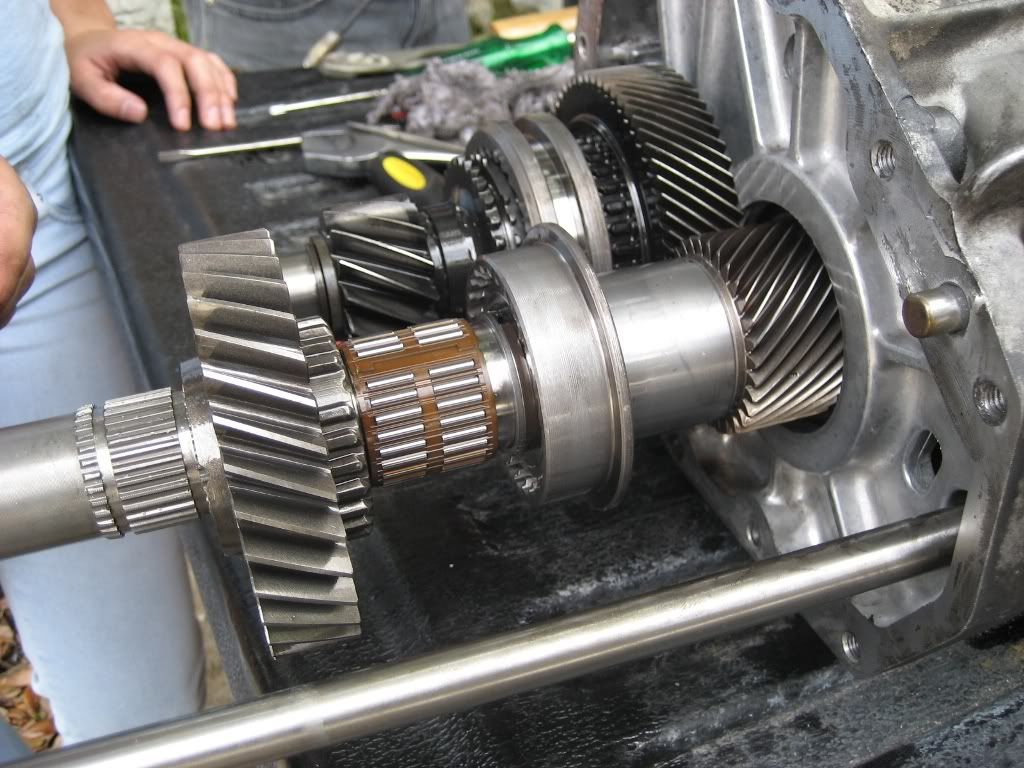

Then, would need a press to take this gear out, but a little hammer did the work..

thanks pomoforacing for this pdf to disassemble the t-45

http://pomoforacing.com/tech/PreliminaryT45rebuild.pdf

I didn't found a lot of info for the t-45, but my trans broke someting, i was able to put the shifter in 1rst, and the trans was in 1rst to, changed the shifter to 2nd or neutral and the trans would still be in 1rs, So i took out the trans from the car myself and opened it with my friends, i found it was the gear shift plate that broke, what was the reason? :shrug: someone here may know i hope, now im looking to upgrade it because i already disassembled it all, do you guys know if any hanlon kit cames with that shifter plate? maybe red98cobrastang knows..

what kit should i get now so it can build an upgraded t-45 tha i won't have to worry for some time?.. i know ill need steel shift forks, what more would you recomend??

the good thing is i did it myself with my friends and learned as always, here are the pics of the progress..

First we took out the bolts of the tailhousing, you'll need to punch a pin that sits where the shifter goes, so you can remove the tailhousing, then it should look like this..

Then remove the bellhousing and you can see the shiter plate broke if you pay attention or if you know the t-45.. i should be like two little "U", but since one broke, thats why i was able to move the shifter, but not the shift forks..

This is the piece that broke, i found someone on stangnet posted that too, but the only reply was "check out d&dmotorsports

Starting from the back, we took the bushing out, and the c-clips we found on the road

Tought that was the problem, Japan Bearings

Since we don't have all the tools, we like to improve, those parts were not born there.. lol

Now, we go to the front..

As always, the last screw was a PITA, aluminum + a steel screw gets real tight as time passes..

We used a torx and we broke it, then we used an air gun, and broke the torx before the screw could move.. it was about 250lb/ft (like 3-4 hondas) and it didn't move. So i learend that if you heat the aluminum, and then use a little wd-40 on the screw, it won't be tight anymore.. it was real cool to see this..

Then, would need a press to take this gear out, but a little hammer did the work..

thanks pomoforacing for this pdf to disassemble the t-45

http://pomoforacing.com/tech/PreliminaryT45rebuild.pdf