Burninrock24

Active Member

I did not compile this info, but it applies to every motor made and is a great technical read for those like me who enjoy this kind of stuff.

Original post here: http://www.d-series.org/forums/engi...-torque-vs-horsepower-debate.html#post1865664

_____________________________________

After hearing/reading so much misinformation regarding torque and horsepower, I figured this write-up was needed. Although I have to go over some basic physics for this article, I’ll keep calculus out of it. Let’s start by going over the relevant terms:

Thrust

Thrust is the force that drives your car forward. It doesn’t matter how much torque your engine makes, what your gearing is, how large your wheels are, how shiny your muffler is, or how many stickers you have on your doors – thrust determines how fast your car can accelerate. In racing, acceleration is what really matters, and there are only a few immediate ways to make your car accelerate faster:

ΣF = ma

Where, ΣF= the sum of the forces acting on the car

m = the mass of the car

a = the acceleration of the car

If you want to increase acceleration, you need to reduce weight, increase thrust, or decrease other forces that oppose thrust (namely drag).

Torque

Torque is a force applied about a moment arm (commonly described as a “twisting” force). Instead of a force that propels an object forward, think of it as a force that causes the object to rotate. If I apply a force about some point, the torque applied is the product of the distance to the point and the portion of the force which is perpendicular to that distance. The equation used to calculate torque is:

τ = Fd

Where, τ = torque

F = the portion of the total force acting perpendicularly to the distance vector

d = the distance between the fulcrum and the point at which the force F is applied

Note that torque is instantaneous. It doesn’t matter how long or the distance over which the force is applied.

Work

Work is the energy used to move an object. Forces and torques might always exist, but unless the object has moved, no work has been performed. If I try to move an object, but I can’t make it budge, then I’m performing no work. I’m using a lot of energy to develop force, but it’s being used to create heat, not to perform work. Once the object moves, then I’m using some of that energy to perform work. The equation used to determine the work performed on an object is:

W = Fx

Where, W = the work performed

F = the force applied to the object

x = the displacement of the object

Work can also be performed on a rotating object, such as a crankshaft. The equation in this case is slightly different:

W = τθ

Where, W = the work performed

τ = the torque applied

θ = the angular displacement (in radians)

Instead of force, torque is used, and the displacement is expressed in radians instead of feet or meters. If an object makes one revolution, its angular displacement is 2π radians (or 360°), if it makes ¼ revolution, its angular displacement is π/2 radians (or 90°), etc. Based on this equation, it should be apparent that torque is not a measure of work. If torque is applied to a shaft, but it does not rotate, no work is performed. It’s a little confusing since both have the same units, but they do not measure the same quantities.

Power

Power is a measure of how much work is performed (or energy used) per unit of time. It doesn’t measure how much torque is applied over time, just the work performed. For engines, the unit “horsepower” is used. If an engine produces 1 hp, then it can perform 550 ft-lb of work (not torque) every second. It doesn’t matter if the engine produces 1 ft-lb of torque or 100 ft-lb of torque. The equation for power is:

P = Fv

Where, P = power

F = the force applied

v = the velocity at which the force is applied

For a rotating object, it’s:

P = τω

Where, P = power

τ = the torque applied

ω = the rotational speed at which the torque is applied

For engines, we commonly see the equation: Horsepower = (Torque)*(RPM) / 5252

However, what does this really mean? Where does the constant 5252 come from?

Calculating Horsepower

As mentioned, power can be calculated by multiplying the torque applied to a rotating object by the speed at which it rotates. However, the base unit for rotational speed is radians per second, and we normally measure engine speed in revolutions per minute. Therefore, if we want to use rpm, we need to convert. Since there are 2π radians in one revolution, and 60 seconds in one minute, we have to divide by 60 and multiply by 2π:

P = (Torque) * (RPM) * (1 min / 60 s) * (2π rad / 1 rev) = 2π*(Torque)*(RPM) / 60

Next, we want power expressed in horsepower, not ft-lb/s (which is the base unit). Therefore, we need to divide by 550:

Horsepower = 2π*(Torque) *(RPM) / (60 * 550) = 2π*(Torque) *(RPM) / 33000

Since 33000/2π is about 5252, we just use: Horsepower = (Torque)*(RPM) / 5252

Now you can see that it’s not just a random equation with a meaningless result. It’s a measure of the rate at which energy is produced and the rate at which work is performed.

So What?

By now, you’re probably getting tired of my physics lesson, so I’ll move on. How do we use this information to design our engines? Do we want to produce tons of torque like a diesel engine or gobs of horsepower like a motorcycle engine? Let’s take a look at some examples.

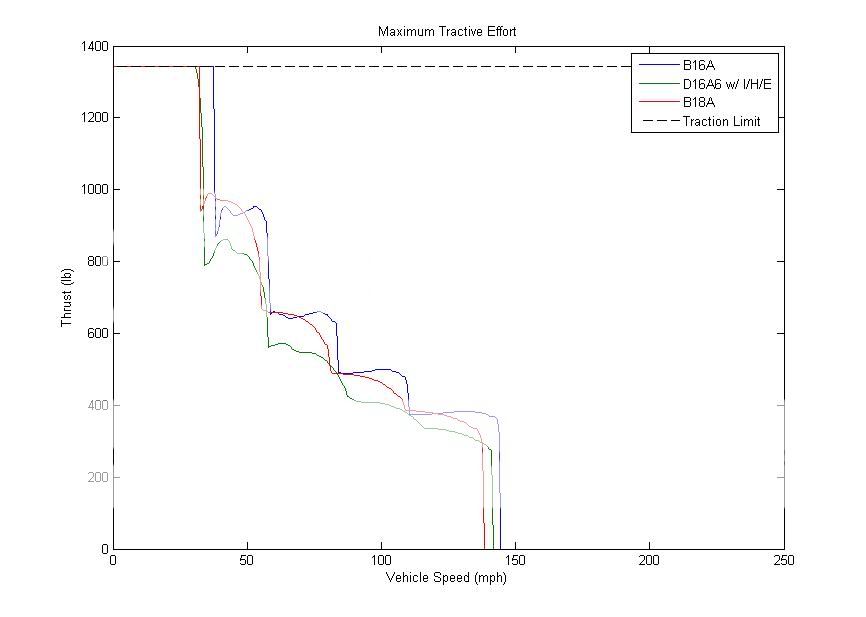

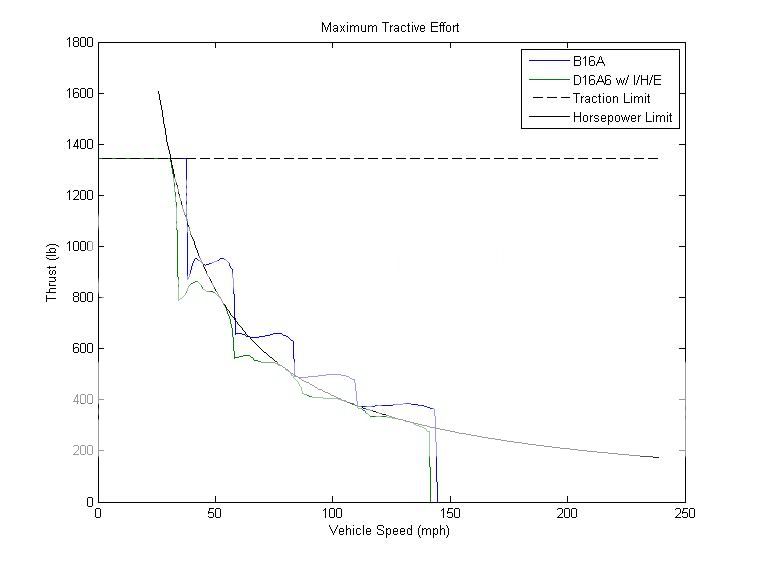

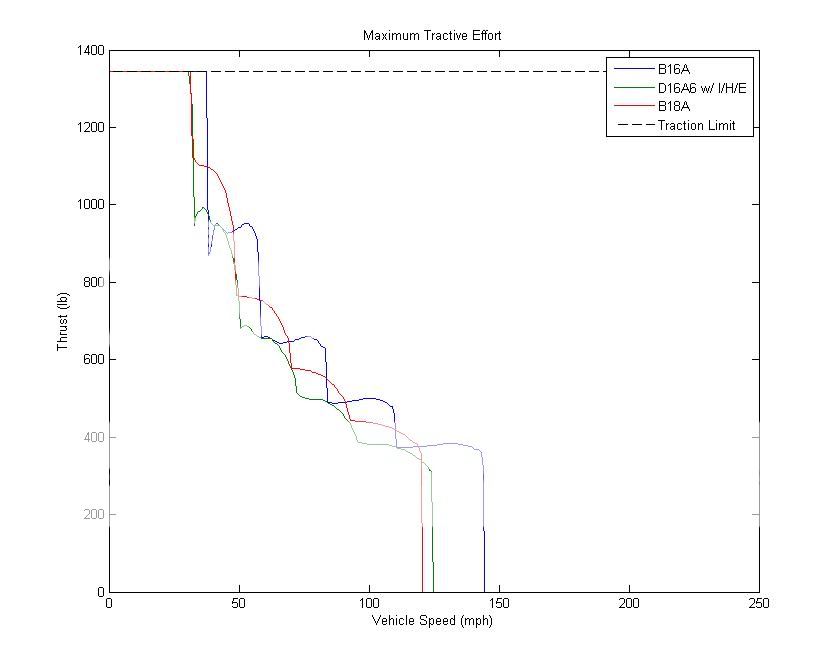

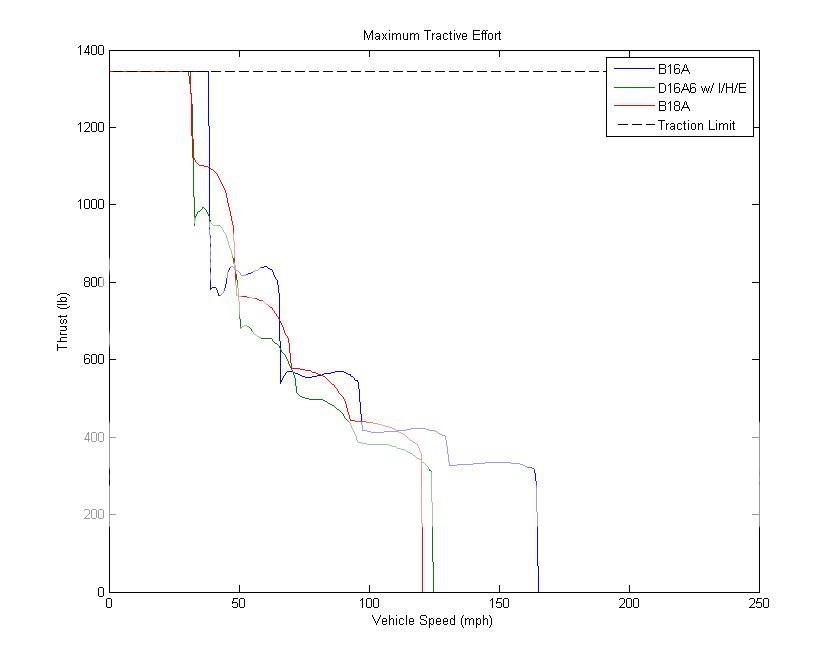

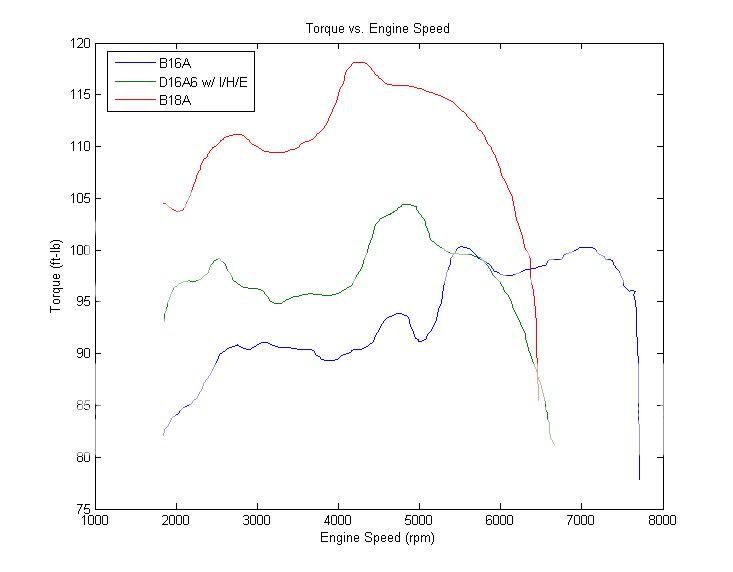

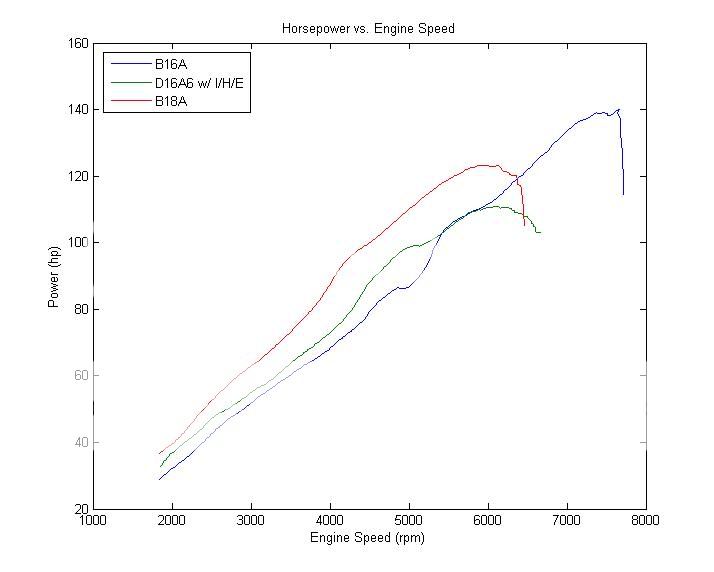

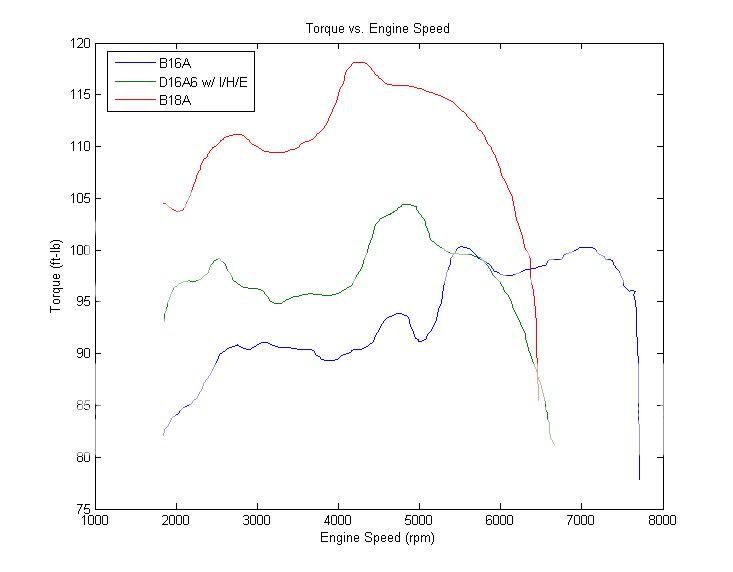

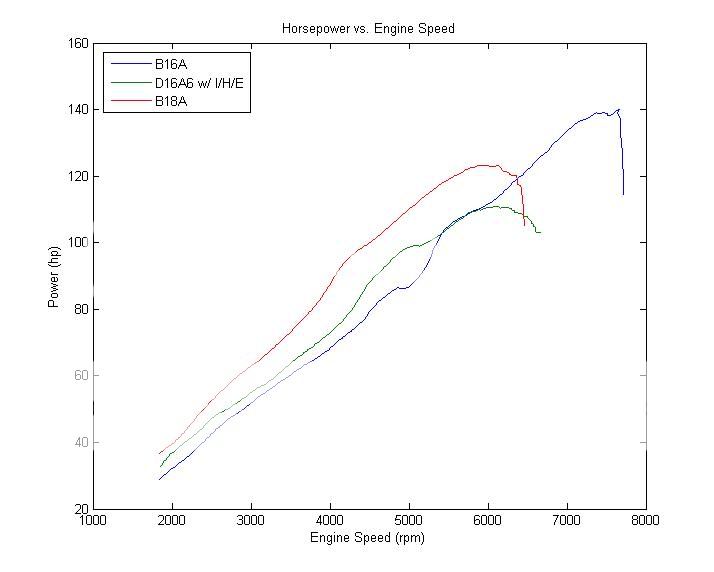

I did a little searching and found a dyno plot from Race Prep Engineering which contains results from three different engines: a b16a, a d16a6, and a b18a. I digitized the curves and recreated them for you:

As seen in the graphs, the b16a produces 100.3 ft-lb of torque and 140.1 whp, the d16a6 produces, 104.5 ft-lb of torque and 110.9 whp, and the b18a produces 118.1 ft-lb of torque and 123.3 whp. As expected, the b16a makes the least torque but the most horsepower, the b18a makes the most torque, and the d16a6 makes the least horsepower. These curves are useful by themselves, but they don’t tell us anything about thrust, which is what we really care about. So, we need to do a little math. First, I needed the gear ratios for the transmissions used with each engine:

I’ll also assume that each engine/transmission is used with a 23.4” tire. Using this information, and assuming perfect launches and shift points, we can figure out how much thrust each setup will produce at any speed.

However, there’s a catch. At low speeds, there may be too much thrust for the tires to handle, and they’ll spin. If the tires are spinning, they cannot develop as much force as if they were rolling (or slightly slipping, which is most desirable). Therefore, the car cannot use more thrust than its traction limit. Without going into too much detail, the traction limit of a car (at steady-state) is dictated by its center of gravity, weight, wheelbase, and tires. When the car is launched, these factors affect how much weight is transferred from the front wheels to the rear wheels. However, FWD cars want as much load on the drive wheels as possible, and weight transfer works against them. This puts them at a major disadvantage for drag racing. I’ll spare everyone the math, but in this example, I’ve estimated that the traction limit is about 1344 lb for a typical Civic using street tires, which corresponds to a maximum acceleration of about 0.54 g.

Original post here: http://www.d-series.org/forums/engi...-torque-vs-horsepower-debate.html#post1865664

_____________________________________

After hearing/reading so much misinformation regarding torque and horsepower, I figured this write-up was needed. Although I have to go over some basic physics for this article, I’ll keep calculus out of it. Let’s start by going over the relevant terms:

Thrust

Thrust is the force that drives your car forward. It doesn’t matter how much torque your engine makes, what your gearing is, how large your wheels are, how shiny your muffler is, or how many stickers you have on your doors – thrust determines how fast your car can accelerate. In racing, acceleration is what really matters, and there are only a few immediate ways to make your car accelerate faster:

ΣF = ma

Where, ΣF= the sum of the forces acting on the car

m = the mass of the car

a = the acceleration of the car

If you want to increase acceleration, you need to reduce weight, increase thrust, or decrease other forces that oppose thrust (namely drag).

Torque

Torque is a force applied about a moment arm (commonly described as a “twisting” force). Instead of a force that propels an object forward, think of it as a force that causes the object to rotate. If I apply a force about some point, the torque applied is the product of the distance to the point and the portion of the force which is perpendicular to that distance. The equation used to calculate torque is:

τ = Fd

Where, τ = torque

F = the portion of the total force acting perpendicularly to the distance vector

d = the distance between the fulcrum and the point at which the force F is applied

Note that torque is instantaneous. It doesn’t matter how long or the distance over which the force is applied.

Work

Work is the energy used to move an object. Forces and torques might always exist, but unless the object has moved, no work has been performed. If I try to move an object, but I can’t make it budge, then I’m performing no work. I’m using a lot of energy to develop force, but it’s being used to create heat, not to perform work. Once the object moves, then I’m using some of that energy to perform work. The equation used to determine the work performed on an object is:

W = Fx

Where, W = the work performed

F = the force applied to the object

x = the displacement of the object

Work can also be performed on a rotating object, such as a crankshaft. The equation in this case is slightly different:

W = τθ

Where, W = the work performed

τ = the torque applied

θ = the angular displacement (in radians)

Instead of force, torque is used, and the displacement is expressed in radians instead of feet or meters. If an object makes one revolution, its angular displacement is 2π radians (or 360°), if it makes ¼ revolution, its angular displacement is π/2 radians (or 90°), etc. Based on this equation, it should be apparent that torque is not a measure of work. If torque is applied to a shaft, but it does not rotate, no work is performed. It’s a little confusing since both have the same units, but they do not measure the same quantities.

Power

Power is a measure of how much work is performed (or energy used) per unit of time. It doesn’t measure how much torque is applied over time, just the work performed. For engines, the unit “horsepower” is used. If an engine produces 1 hp, then it can perform 550 ft-lb of work (not torque) every second. It doesn’t matter if the engine produces 1 ft-lb of torque or 100 ft-lb of torque. The equation for power is:

P = Fv

Where, P = power

F = the force applied

v = the velocity at which the force is applied

For a rotating object, it’s:

P = τω

Where, P = power

τ = the torque applied

ω = the rotational speed at which the torque is applied

For engines, we commonly see the equation: Horsepower = (Torque)*(RPM) / 5252

However, what does this really mean? Where does the constant 5252 come from?

Calculating Horsepower

As mentioned, power can be calculated by multiplying the torque applied to a rotating object by the speed at which it rotates. However, the base unit for rotational speed is radians per second, and we normally measure engine speed in revolutions per minute. Therefore, if we want to use rpm, we need to convert. Since there are 2π radians in one revolution, and 60 seconds in one minute, we have to divide by 60 and multiply by 2π:

P = (Torque) * (RPM) * (1 min / 60 s) * (2π rad / 1 rev) = 2π*(Torque)*(RPM) / 60

Next, we want power expressed in horsepower, not ft-lb/s (which is the base unit). Therefore, we need to divide by 550:

Horsepower = 2π*(Torque) *(RPM) / (60 * 550) = 2π*(Torque) *(RPM) / 33000

Since 33000/2π is about 5252, we just use: Horsepower = (Torque)*(RPM) / 5252

Now you can see that it’s not just a random equation with a meaningless result. It’s a measure of the rate at which energy is produced and the rate at which work is performed.

So What?

By now, you’re probably getting tired of my physics lesson, so I’ll move on. How do we use this information to design our engines? Do we want to produce tons of torque like a diesel engine or gobs of horsepower like a motorcycle engine? Let’s take a look at some examples.

I did a little searching and found a dyno plot from Race Prep Engineering which contains results from three different engines: a b16a, a d16a6, and a b18a. I digitized the curves and recreated them for you:

| This image has been resized. Click this bar to view the full image. |

As seen in the graphs, the b16a produces 100.3 ft-lb of torque and 140.1 whp, the d16a6 produces, 104.5 ft-lb of torque and 110.9 whp, and the b18a produces 118.1 ft-lb of torque and 123.3 whp. As expected, the b16a makes the least torque but the most horsepower, the b18a makes the most torque, and the d16a6 makes the least horsepower. These curves are useful by themselves, but they don’t tell us anything about thrust, which is what we really care about. So, we need to do a little math. First, I needed the gear ratios for the transmissions used with each engine:

I’ll also assume that each engine/transmission is used with a 23.4” tire. Using this information, and assuming perfect launches and shift points, we can figure out how much thrust each setup will produce at any speed.

However, there’s a catch. At low speeds, there may be too much thrust for the tires to handle, and they’ll spin. If the tires are spinning, they cannot develop as much force as if they were rolling (or slightly slipping, which is most desirable). Therefore, the car cannot use more thrust than its traction limit. Without going into too much detail, the traction limit of a car (at steady-state) is dictated by its center of gravity, weight, wheelbase, and tires. When the car is launched, these factors affect how much weight is transferred from the front wheels to the rear wheels. However, FWD cars want as much load on the drive wheels as possible, and weight transfer works against them. This puts them at a major disadvantage for drag racing. I’ll spare everyone the math, but in this example, I’ve estimated that the traction limit is about 1344 lb for a typical Civic using street tires, which corresponds to a maximum acceleration of about 0.54 g.