well this project ended up taking longer than planned after we discovered a rotted/molding wall in the basement where I planned to put this. The basement is unfinished and just a storage/work space for the past 40 yrs so it meant there was a lot of crap that needed to be thrown out as well as just everything moved away from the wall so it could be replaced. It ended up taking a few weeks longer than planned because of it. The old cnc had a 6" x 8" cutting area and weighs 45 lbs. This one has a 32" x 32" so it takes up a lot more space and weighs a 125 lbs so it needed a solid table to start.

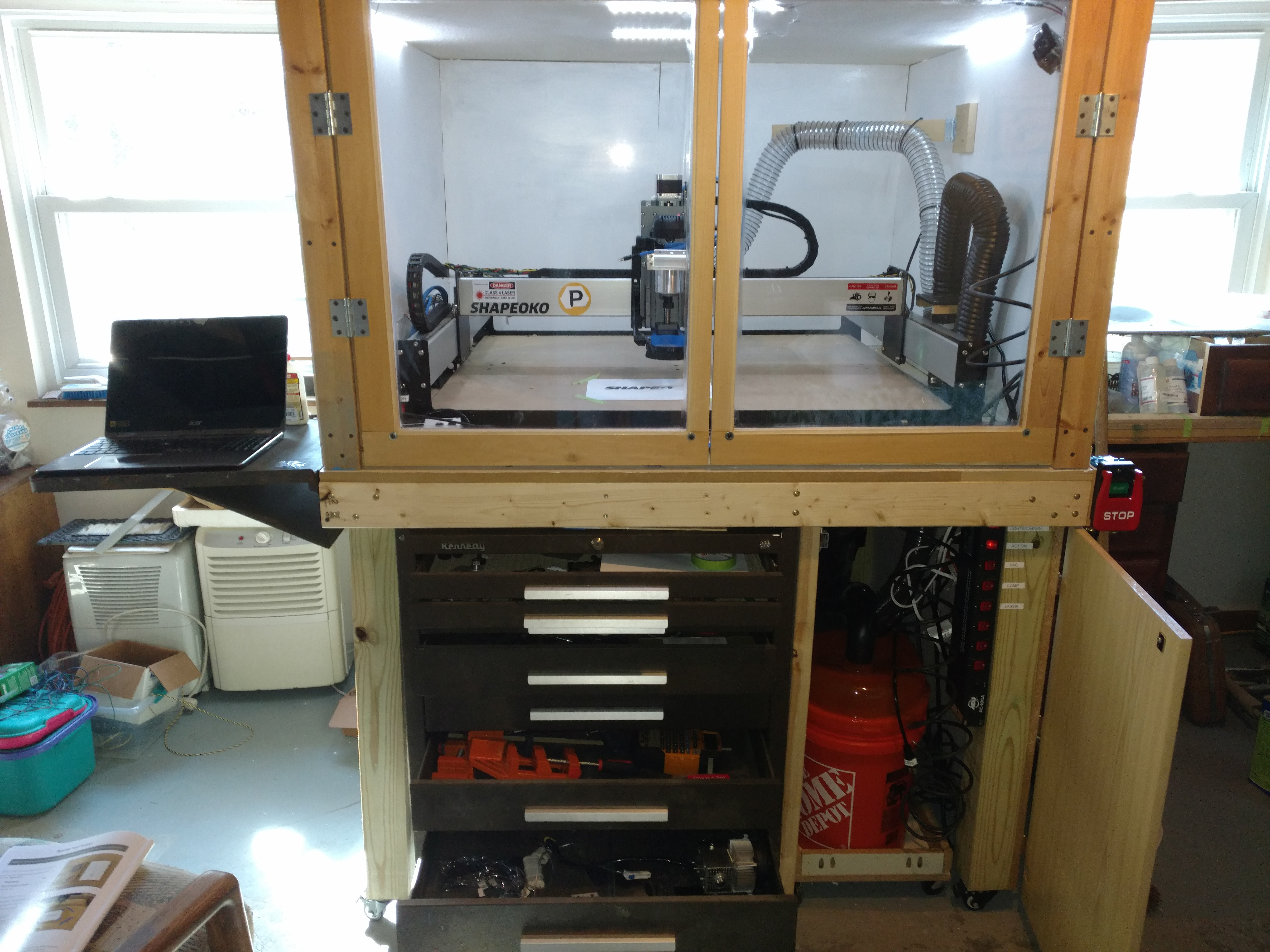

I also wanted to have some drawers for all the extras that go with it but didn't really want to take the time to design/cut/make shelves/drawers so after a quick search I found this kennedy toolbox at a local swap meet for $100. It was just short enough to slide under it and leave space on the side for the vac/dust collection and a compressor. After that I put the top on, built the enclosure and then put the cnc together.

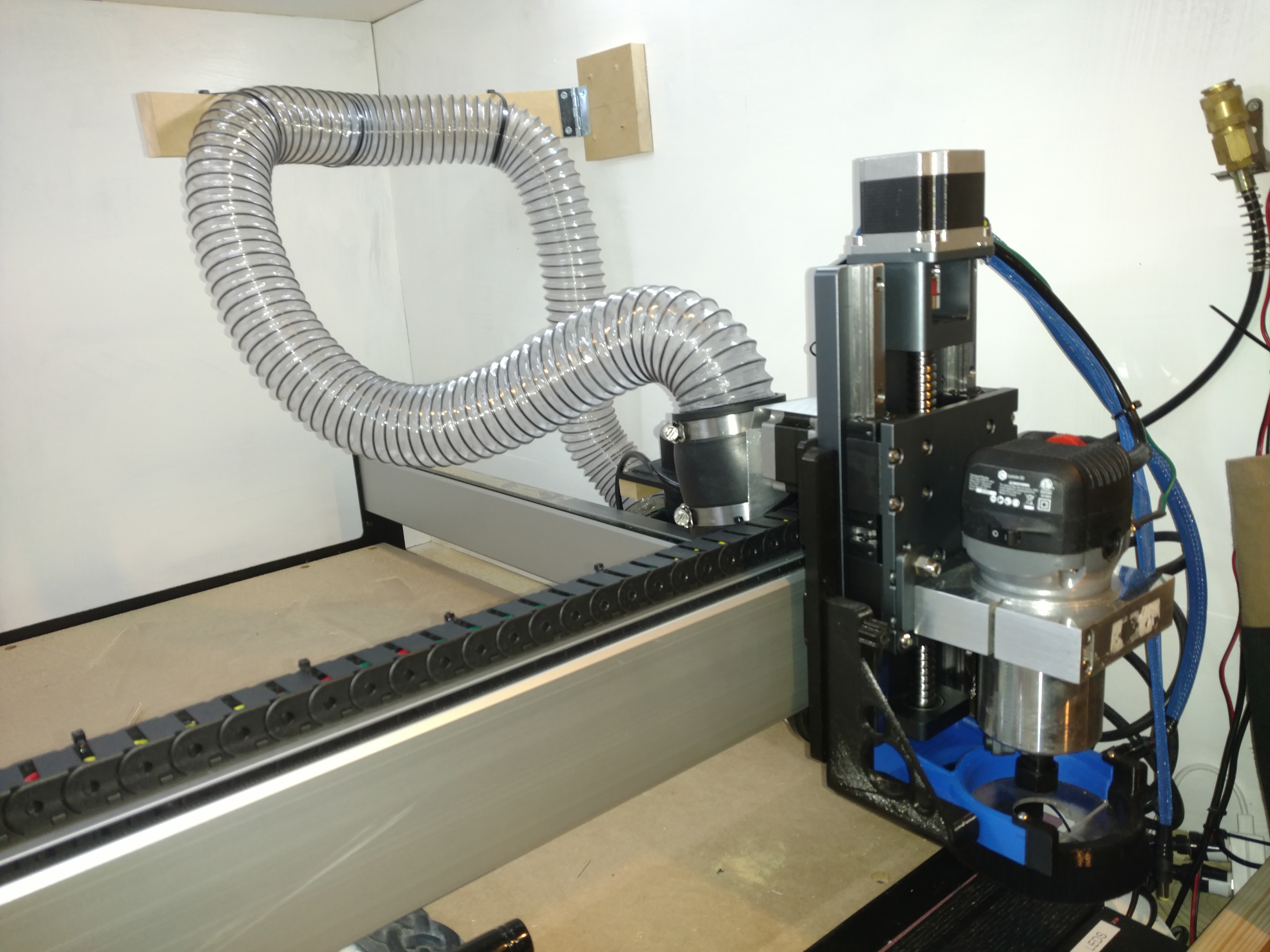

I included an emergency stop on the right side to kill power to everything in case the shit hits the fan, as well as used a an automotive keyless entry to work as a remote pause system that will kill power to the spindle and pull it back from the work but not kill power to everything. With my gopro on the top right I will be able to remotely monitor it and pause it if needed. The kennedy box had a fold out work space on the side that I removed and then stuck on the side of the table for my laptop.

did I mention there was a lot going on in a small area?

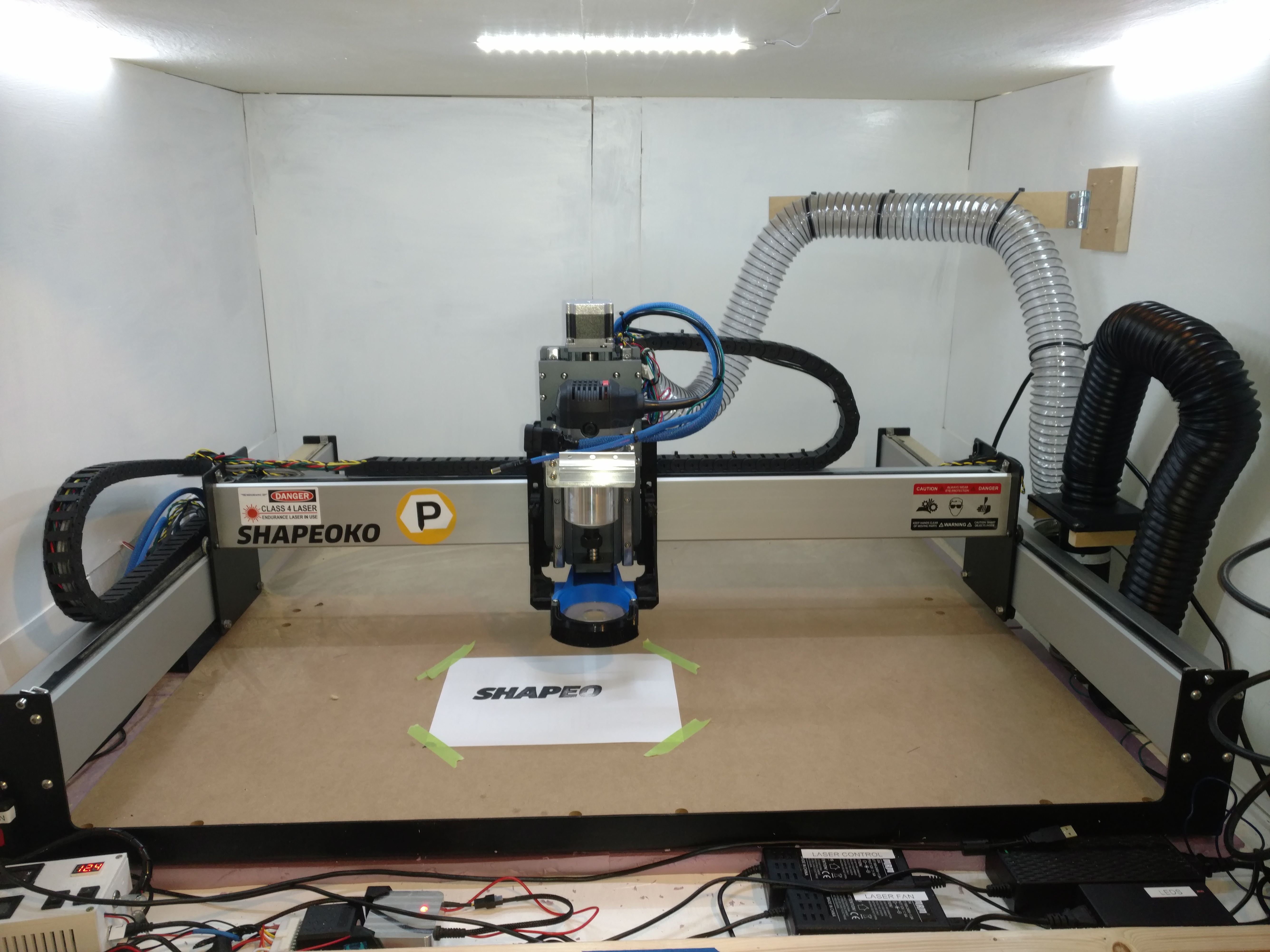

this was a test program to make sure its all working.

at the bottom of the pic you can see the laser power source(far left), touch probe(the red light, this automatically sets the Z to zero for you) and the keyless entry to pause it. now I wish with this said that I could start making cool stuff but I still have some more stuff to set up. I need to make and then deck the board that goes on the bottom so that I can easily mount things to it and make sure its perfectly flat. I also need to make a bracket for the laser but I want to do that with the cnc so that will be after decking the spoil board.

Unfortunately I am waiting on some parts for that, so while I wait for that shtuff I am going to get back in the car and see if, sorry I mean to say see "how long" it takes for it to piss me off again. Not sure why, it was starting up and sounded so nice till suddenly it wasn't and now it will not start at all. After being so close to hoping it was on the road and taking 3 steps back to "I don't know what the ffffffff is wrong again" left me in a place where I considered saying F-it and starting a parts sale. I decided to take a step back from it and work on this in hopes that this could bring a little satisfaction in the end. I am going to start simple and replace the plugs, again and see where that leads.