Casper98gt

New Member

- Joined

- Jul 3, 2007

- Messages

- 52

- Reaction score

- 0

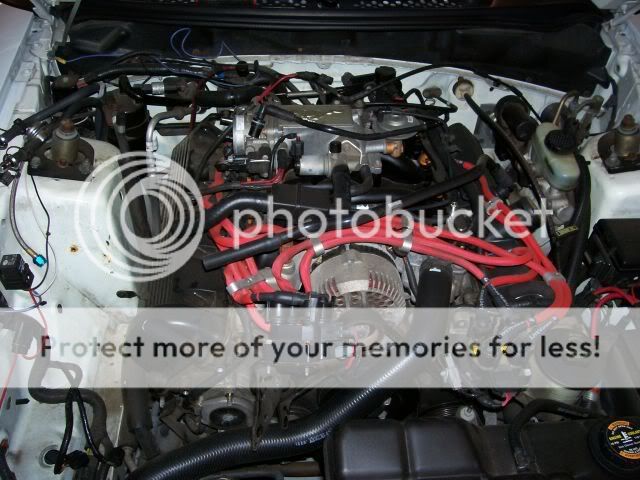

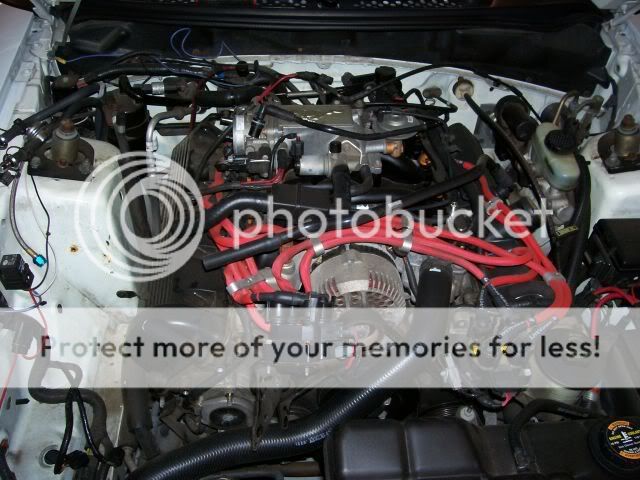

Well, i installed the PI cams in my NPI 98 Gt today.

Started out with: Cams, Cam bolts, 6 qts. Mobil 1 oil and Motorcraft filter, assembly lube, 180 degree thermostat.

Started off by yanking the CAI out of my way and nitrous silinoids. Took my IAC hose and PCV hose out of the way. Then started taking the bolts out of the valve cover on the right side. You will need a swivel 8mm, a deep 8 mm and a 13mm deep socket. There are all 8mm except the one at the back of the cover is a 13mm.

Once i got all the bolts out there is silicone at the front where the valve cover meets the front cover. So use a scraper or razor blade to get it off. Once everything is clear the cover can come off.

After the valve cover is off you can now see the cam exposed. First i use the Ford tool to jam in the timing chain so the timing doesnt jump on me. I dont remove the front cover when i do cams. But if you dont have the right tools then youre probably going to. Alot of garages will remove the front cover and re-time. But i dont. Then i used another Ford tool to remove the roller follwers.

After all 8 rollers are out of my way now i could remove the 10mm bolts holding down the girdles. Which in my thoughts are the biggest pieces of trash ever. They are cheap aluminum and they break....trust me. So after the number 3/4 girdle cracking i used my diegrinder and cut them up so they are now just cam caps like the PI motors use. So now all the bolts are out and girdles are off, now time to remove the cam gear. I used my impact gun with 18mm socket. Buzzed it off and slid the gear off. Put in the new cam and used assembly lube excessivly. Put the cam girdles back on and modified one in the rear. Then torqued down the cam girdles to 100 inch lbs. Then torqued down the cam gear to 95 ft. lbs.

If you notice in the picture the rear 3/4 girdles are modified. But thats only because they cracked.

Now i can put the rockers back in. Putting each cam lobe to the top and installing them one by one. Its now time to install the valve cover. I bought 2 brand new valve covers with gaskets in them from ebay shipping to my house for 12 dollars. So now i have new valve covers, clean!! Now its time for the other side.

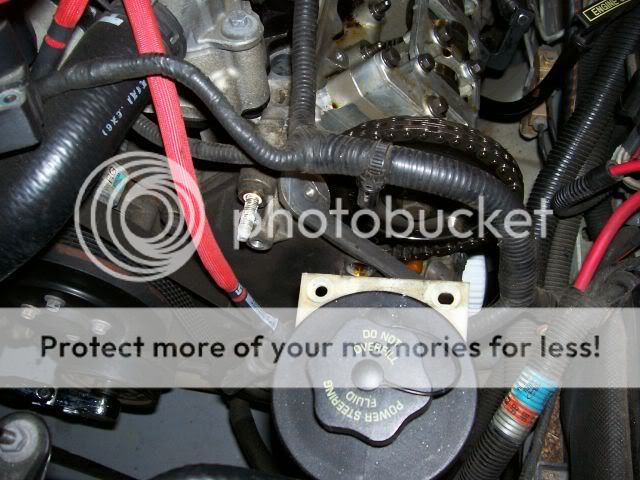

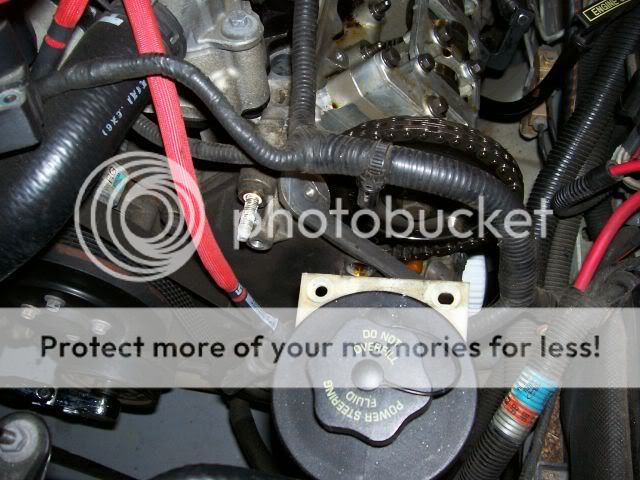

So the other side was a bit more time consuming, but i took quick care of it. Start by removeing all the plug wires out of the way. Then i removed the coil pack out of my way, followed by the powersteering res. with 3 10mm bolts, 2 on top and one on the left side.

Now i can get to the multiple 13mm bolts and nuts on the bracket in front of the head. Once out of my way i cleaned it up. Removed the cam sensor and set aside. Remove the valve cover and cleaned up the head. Removed the girdles, and rockers. Removed the cam and put more lube on it before assembly.

Now you can reassemble. Put back together the same as the other side. Put my oil in and drained the coolant real quick and threw in the 180 stat.

Now i was ready to fire it up.

Started good and sounds very nice.

Just a few things i have noticed.

First off it runs better, i dunno why but it does. The motor doesnt shake NEARLY as much now.

Sounds much louder. Not so much the CAM sound, but alot differerent sound.

Much more powerful above 2700rpms. I only pulled up to 5k rpms, but much better. Stronger and along with the PI intake i have it feels alot stronger then a stock 99+ car.

When i take the car up to 3-4k rpms and let off....it comes down alot better and is much more responsive.

Next to dyno it. :banana: O0

Started out with: Cams, Cam bolts, 6 qts. Mobil 1 oil and Motorcraft filter, assembly lube, 180 degree thermostat.

Started off by yanking the CAI out of my way and nitrous silinoids. Took my IAC hose and PCV hose out of the way. Then started taking the bolts out of the valve cover on the right side. You will need a swivel 8mm, a deep 8 mm and a 13mm deep socket. There are all 8mm except the one at the back of the cover is a 13mm.

Once i got all the bolts out there is silicone at the front where the valve cover meets the front cover. So use a scraper or razor blade to get it off. Once everything is clear the cover can come off.

After the valve cover is off you can now see the cam exposed. First i use the Ford tool to jam in the timing chain so the timing doesnt jump on me. I dont remove the front cover when i do cams. But if you dont have the right tools then youre probably going to. Alot of garages will remove the front cover and re-time. But i dont. Then i used another Ford tool to remove the roller follwers.

After all 8 rollers are out of my way now i could remove the 10mm bolts holding down the girdles. Which in my thoughts are the biggest pieces of trash ever. They are cheap aluminum and they break....trust me. So after the number 3/4 girdle cracking i used my diegrinder and cut them up so they are now just cam caps like the PI motors use. So now all the bolts are out and girdles are off, now time to remove the cam gear. I used my impact gun with 18mm socket. Buzzed it off and slid the gear off. Put in the new cam and used assembly lube excessivly. Put the cam girdles back on and modified one in the rear. Then torqued down the cam girdles to 100 inch lbs. Then torqued down the cam gear to 95 ft. lbs.

If you notice in the picture the rear 3/4 girdles are modified. But thats only because they cracked.

Now i can put the rockers back in. Putting each cam lobe to the top and installing them one by one. Its now time to install the valve cover. I bought 2 brand new valve covers with gaskets in them from ebay shipping to my house for 12 dollars. So now i have new valve covers, clean!! Now its time for the other side.

So the other side was a bit more time consuming, but i took quick care of it. Start by removeing all the plug wires out of the way. Then i removed the coil pack out of my way, followed by the powersteering res. with 3 10mm bolts, 2 on top and one on the left side.

Now i can get to the multiple 13mm bolts and nuts on the bracket in front of the head. Once out of my way i cleaned it up. Removed the cam sensor and set aside. Remove the valve cover and cleaned up the head. Removed the girdles, and rockers. Removed the cam and put more lube on it before assembly.

Now you can reassemble. Put back together the same as the other side. Put my oil in and drained the coolant real quick and threw in the 180 stat.

Now i was ready to fire it up.

Started good and sounds very nice.

Just a few things i have noticed.

First off it runs better, i dunno why but it does. The motor doesnt shake NEARLY as much now.

Sounds much louder. Not so much the CAM sound, but alot differerent sound.

Much more powerful above 2700rpms. I only pulled up to 5k rpms, but much better. Stronger and along with the PI intake i have it feels alot stronger then a stock 99+ car.

When i take the car up to 3-4k rpms and let off....it comes down alot better and is much more responsive.

Next to dyno it. :banana: O0