DONT DO IT!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Porting pi heads

- Thread starter 96blak54

- Start date

What is the biggest reason not to port pi heads?

The flow bench!

Yes, porting the heads will produce results on a flow bench and hp will be gained when used on an engine, but porting may kill what the heads design is intended for.....and this does not show up on a flow bench.

Question remains......whats left on the table when porting pi heads? (Or any head)

Yes, porting the heads will produce results on a flow bench and hp will be gained when used on an engine, but porting may kill what the heads design is intended for.....and this does not show up on a flow bench.

Question remains......whats left on the table when porting pi heads? (Or any head)

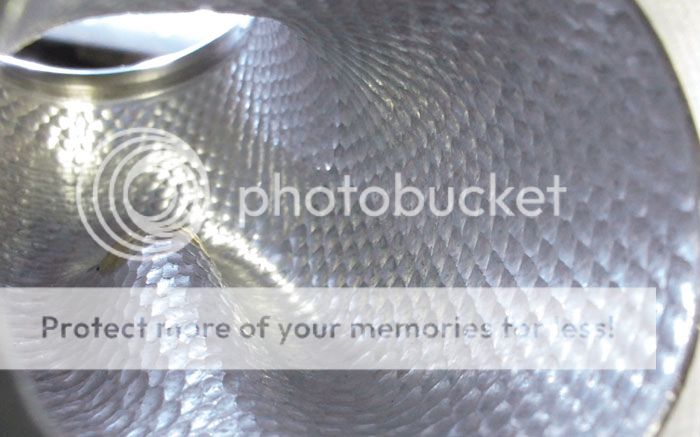

Lets discuss what we see in this pic of a 100k mile pi intake port.

The port is nasty oil covered! Thats obvious! This oil covering is due to the PCV needing an inline oil catch. Overhead cams spinning fast, slinging oil into tiny droplets will get pulled out by the PCV vacuum straight to the intake tract, ultimately throughout the intake manifold and into the combustion chamber.

Although the oil tracking is bad for performance, .... its great for this pic!

See the clean-er area towards the bowl? Why isnt the black oil in them spots? Why is it clean?

Although the oil tracking is bad for performance, .... its great for this pic!

See the clean-er area towards the bowl? Why isnt the black oil in them spots? Why is it clean?

Burninriverdiver

Well-Known Member

- Joined

- Jan 1, 2014

- Messages

- 2,770

- Reaction score

- 234

You are definitely asking questions I would like to know! When I swapped my cams and intake this winter, I noticed the same buildup on the top of my NPI heads. I changed the PCV twice and it still smokes slightly out of the exhaust. Installing an inline oil catch would be much less labor intensive than valve seals if that is what causes part of the issue. This thread is heading in a good direction

Wichers123

Well-Known Member

Looks like the fuel is washing down the port, which is shit. Cfm is cfm is cfm. If the engine can't draw in more cfm then the power output is limited to that cfm. Now yeah the port design maybe good but cfm is also where it's at. If you can cnc the port in the exact shape and make it flow say 300 at .550 lift then shit you got a damn good head.

You are correct wichers123! Fuel always washes the port walls just before the valve. Also washes valve seats and valve back. This is typical of a port injected engine....nothing new here. As for cfm, again you are correct.... Straight to the point! Thats what I like about your post....truth! But....a slight problem here with a single intake valve pi head. Only so much air can pass through a valve. Is it possible to obtain more cfm with the stock valve hole by porting... Absolutely! Now the question remains....after porting, wil the heads potential for hp still be the same? NO it will not....unless you know what you're doing. Pi heads can be destroyed very easily! Most of the port work youll want to do stays away from the valve area. "Touching up" "smoothing out" "blending" or aftermarket valves all destroy what the head is designed to do. Killing potential for stable hp! We will break this down into a science to better understand why.

More, more, more, I need to know before the NPI's come off and I make them look like the first the first pic PI's, I am your guinea pig. I do not care what I ruin, I will get some more and get it right. Loved the pic of the 5.4 exhaust ports you put up. I can weld up areas and go again, then cut them in half and look see, and get them sweet the 3rd. time.

^ I like this guy! Always wanting to try more.

Check out the Moody Diagram here: https://en.wikipedia.org/wiki/Reynolds_number

Explains a lot about the valve stem sticking out in the flow channel of the port. Sorry... your thread, I get excited, I will be quiet and sit on my hands (squirming).

Explains a lot about the valve stem sticking out in the flow channel of the port. Sorry... your thread, I get excited, I will be quiet and sit on my hands (squirming).

Wichers123

Well-Known Member

96blak54 I understand the idea of what the port is supposed to do but can you just make it flow better? I mean if you go bigger valve you just adding more shrouded area to the valve. If anything blend the seat into the port then work on the roof don't **** with the floor just blend and sharpen the guide. After all that cut out the intake shroud and blend to the rest of the bowl. Now the valve has less shrouded area and should be able to flow more cfm.

Wichers123

Well-Known Member

Btw I did what you did and ported on the car and learned why not too. A couple of flakes stuck to the valve stem and gulled up the stem and guide. I would recommend the next set you do is pull them.Check out the Moody Diagram here: https://en.wikipedia.org/wiki/Reynolds_number

Explains a lot about the valve stem sticking out in the flow channel of the port. Sorry... your thread, I get excited, I will be quiet and sit on my hands (squirming).

Im compiling pics now to fully explain the purpose of the design. Give me a little bit. Wichers, youre right. More cfm is vital to rpm production. If the port can not support the demand of the pistons speed during intake...a wall happens. Kinda like sucking through diffrent diameters of straws. Adding a bigger diameter valve actually is a great idea cause the stock valve is beyond shrouded. More like 70% walled! Adding a tad more area would help. The walling around the valve is equally important to why a port injected 2v has adavantages over a port injected 4v. Also note the pi valve cup shape on the face.....VERY IMPORTANT!

The moody diagram is great info! Thanks OLD H2S.

The moody diagram is great info! Thanks OLD H2S.

Wichers123

Well-Known Member

Im compiling pics now to fully explain the purpose of the design. Give me a little bit. Wichers, youre right. More cfm is vital to rpm production. If the port can not support the demand of the pistons speed during intake...a wall happens. Kinda like sucking through diffrent diameters of straws. Adding a bigger diameter valve actually is a great idea cause the stock valve is beyond shrouded. More like 70% walled! Adding a tad more area would help. The walling around the valve is equally important to why a port injected 2v has adavantages over a port injected 4v. Also note the pi valve cup shape on the face.....VERY IMPORTANT!

The moody diagram is great info! Thanks OLD H2S.

Okay cant ant wait to see it. In the perfect world the valves would be horizontal to the piston and direct center of the cylinder. Valves wouldn't need lash or rockers just direct shim over bucket then the valve train would have even less weight and could rev to the moon.

Homogeneous or heterogeneous. Homo means together uniform throughout. Hetero means together but un-uniform.

Suger dessolved into water = homogeneous

Sugar granules in water = heterogeneous

When the incoming air meets fuel the 2 parts need to mix uniformly into a homogeneous state when entering the cylinder. Sort of like a foggy morning. Microscopic droplets of liquid suspended within the air. The more uniform, the more resistance to preignition, better flame propagation, and less advance timing at early rpm.

Heterogeneous means the fuel is still a liquid state...big blobs of liquid flying about in the air not mixing. Probable preignition, higher chance of detonation, poor flame propagation, and increased advance timing at lower rpm's.

Suger dessolved into water = homogeneous

Sugar granules in water = heterogeneous

When the incoming air meets fuel the 2 parts need to mix uniformly into a homogeneous state when entering the cylinder. Sort of like a foggy morning. Microscopic droplets of liquid suspended within the air. The more uniform, the more resistance to preignition, better flame propagation, and less advance timing at early rpm.

Heterogeneous means the fuel is still a liquid state...big blobs of liquid flying about in the air not mixing. Probable preignition, higher chance of detonation, poor flame propagation, and increased advance timing at lower rpm's.

Porting the pi heads destroys all the bumbs, dips, and edges that aid into a homogeneous scenario.

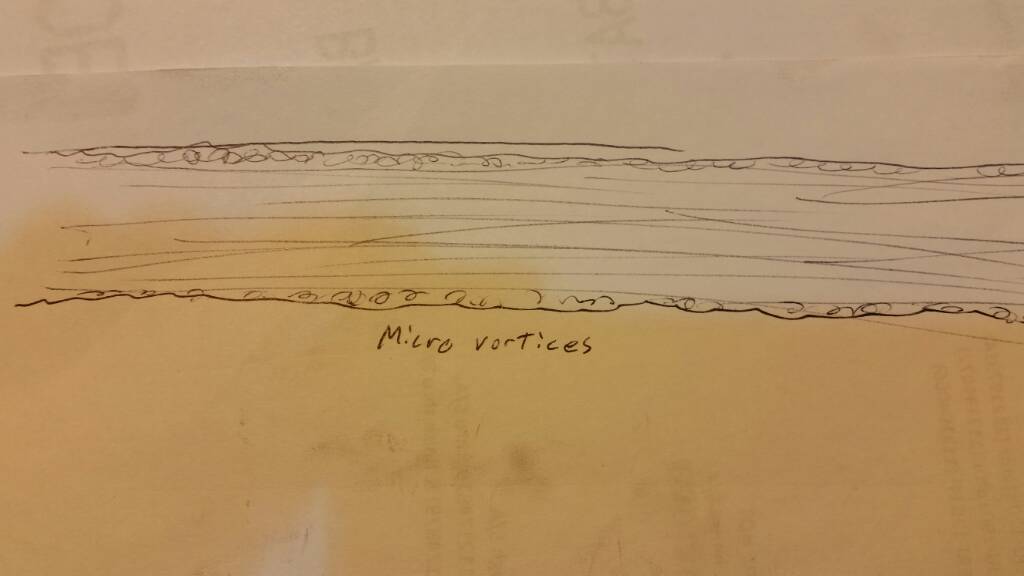

Take for instance the port walls texture. Its know that air does not flow on a surface but flows over it. The smoother it is, the less air flows on it. BUT, fuel will cling to the surface and the smoother the surface the better the fuel clings. Unless the port walls have a texture. This texture disrupts the air flowing over by giving micro bumps and dips as well as peaks that create vortices. When air passes over edges, a low pressure is created (microscopic) and allows for air to flow into and tumble....better known as vortices. These microscopic vortices pick fuel up thats tracking along the port walls and slings it apart throwing it into the incoming charge. These vortices also act like a roller conveyor system, rolling the jet strem through. Smoothing the pi port before the valve seat where the injector sprays will allow fuel to track directly into the chamber. Smooth porting ='s dont do it!

This is a drawn pic to give an idea of vortices along a textured walled pipe.

Take for instance the port walls texture. Its know that air does not flow on a surface but flows over it. The smoother it is, the less air flows on it. BUT, fuel will cling to the surface and the smoother the surface the better the fuel clings. Unless the port walls have a texture. This texture disrupts the air flowing over by giving micro bumps and dips as well as peaks that create vortices. When air passes over edges, a low pressure is created (microscopic) and allows for air to flow into and tumble....better known as vortices. These microscopic vortices pick fuel up thats tracking along the port walls and slings it apart throwing it into the incoming charge. These vortices also act like a roller conveyor system, rolling the jet strem through. Smoothing the pi port before the valve seat where the injector sprays will allow fuel to track directly into the chamber. Smooth porting ='s dont do it!

This is a drawn pic to give an idea of vortices along a textured walled pipe.

Drive down a road on a rainy day without the use of windshield wipers you will see an excellent example of liquid/fuel tracking along a smooth surface. One would think the air would blow the water off clean, but it dont. Liquid clings to smooth.

Wichers123

Well-Known Member

Here's the answer to that.