[MENTION=9659]95opal[/MENTION], it looks like you are running the stifflers lower k member brace - does it clear long tubes? I've been looking at the stifflers products at LMR, looks really nice.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Remove K Member '96 Cobra Convertible - Replace w/ MM Brace?

- Thread starter tcb-1

- Start date

95opal

Well-Known Member

- Joined

- Jun 21, 2007

- Messages

- 3,023

- Reaction score

- 1,605

95opal, it looks like you are running the stifflers lower k member brace - does it clear long tubes? I've been looking at the stifflers products at LMR, looks really nice.

yeah running stifflers k-member brace with the teamz auto- x k-member not running long tubes as I don't want the hassle for the little gain they give.

This is from Brian @stifflers

Within the last year we have redesigned both of 4pt braces which fit the SN95 & New Edge cars and since then have had good success clearing long tubes

Not sure if a specific set of headers will cause issues or not. I would drop them a line just to be sure though.

mineralgreygt

Member

I 2nd 95opal on stifflers products, I have their k member brace on my stock K and it made a very noticeable difference especially in torsion. I used to back out of my sloped driveway at an angle and could always feel the front end twist. After the brace it twists much much less. Brian takes chassis and puts them on a jig and twists them to reveal the chassis weak points that's how he came up with his design. I also have the spider brace waiting to be installed cant wait to feel the difference.

Most people say MM or nothing but there's definitely other companies out their doing it better or differently like Full tilt boogie racing. I plan on installing his IRS bushings over the winter his design is superior to MMs and there's plenty of facts all over the web to prove it. There are many different ways to solve the same problem, some are more efficient than others.

Most people say MM or nothing but there's definitely other companies out their doing it better or differently like Full tilt boogie racing. I plan on installing his IRS bushings over the winter his design is superior to MMs and there's plenty of facts all over the web to prove it. There are many different ways to solve the same problem, some are more efficient than others.

mineralgreygt

Member

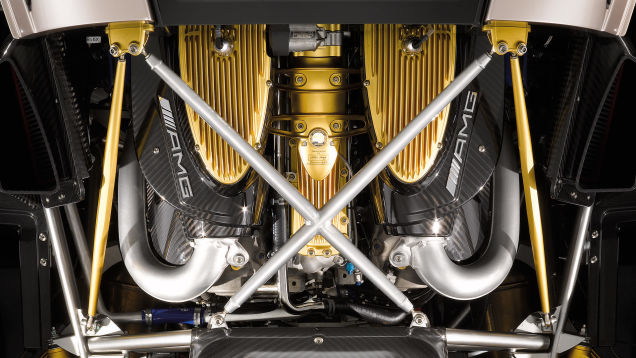

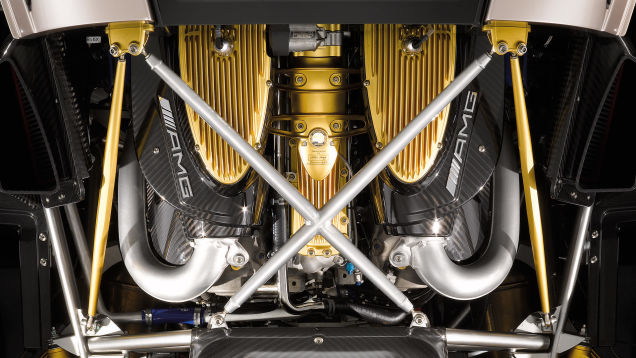

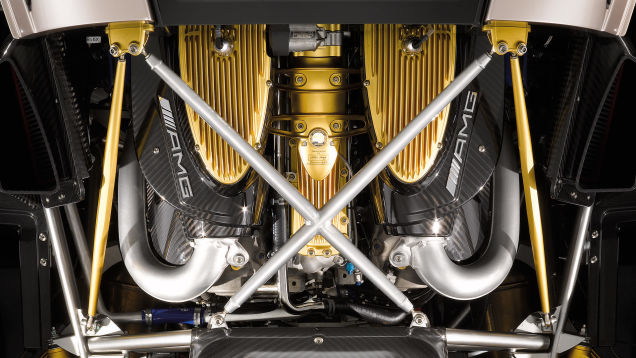

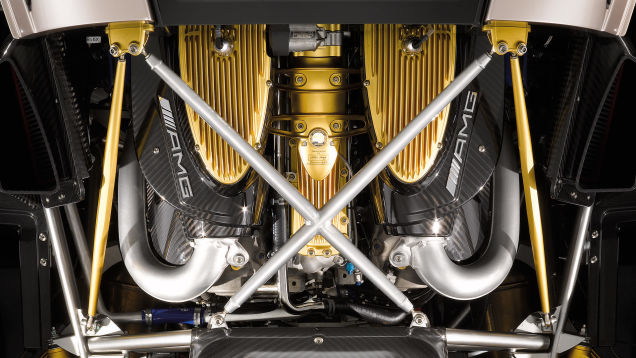

Here's the very same system used on the pagani huayra

95opal

Well-Known Member

- Joined

- Jun 21, 2007

- Messages

- 3,023

- Reaction score

- 1,605

Here's the very same system used on the pagani huayra

Clevis ends and rods are in use throughout all of racing. Its not some unheard of technology until you hit the mustang scene then it becomes a mind**** for the uneducated lol. That pagani is a good example of how they can be used elsewhere on the chassis.

i911fire

New Member

So I know I am late in the game on this but I am really interested in feedback from the guys that are actually running the stifflers setup. I have a '98Cobra Vert with 52k on it. I just bought it and would like to stiffen up the chassis. I have read and heard all of the MM guys, I just want some real accounts from the stifflers guys.

Thanks

Thanks

Here's the very same system used on the pagani huayra

Actually the way this system is very different.

First of all, this is located on top of the engine compartment, which means that it works in conjunction with a very stiff chassis, so you have a rigid structure on top and on the bottom. Secondly, most of the stiffening in that structure comes from the middle piece, which is a welded x brace. Third, it works as support, rather than restraint. This of the chassis as having two major pressure points, which is axles. It will naturally want to bow in in the middle, because that's where all the heavy stuff and the wheels are at the opposite ends of the car. On a Pagani, or any car with engine brace for that matter, the brace is used to support the chassis. The mounting points are up against firewall and the chassis itself, causing a lot of support. The structure under that mustang is essentially keeping the chassis from sagging, by keeping it from being pulled apart. In my opinion, that's not the right way of doing this. I have never seen an under car brace until now that has used this method, including movable rod ends. Usually this is done through a solidly mounted cross brace, which will allow no deflection and no possible movement under load.

mineralgreygt

Member

Actually the way this system is very different.

First of all, this is located on top of the engine compartment, which means that it works in conjunction with a very stiff chassis, so you have a rigid structure on top and on the bottom. Secondly, most of the stiffening in that structure comes from the middle piece, which is a welded x brace. Third, it works as support, rather than restraint. This of the chassis as having two major pressure points, which is axles. It will naturally want to bow in in the middle, because that's where all the heavy stuff and the wheels are at the opposite ends of the car. On a Pagani, or any car with engine brace for that matter, the brace is used to support the chassis. The mounting points are up against firewall and the chassis itself, causing a lot of support. The structure under that mustang is essentially keeping the chassis from sagging, by keeping it from being pulled apart. In my opinion, that's not the right way of doing this. I have never seen an under car brace until now that has used this method, including movable rod ends. Usually this is done through a solidly mounted cross brace, which will allow no deflection and no possible movement under load.

I was referring to the system itself, the threaded rod tubing, not so much the application, unless you have an overkill brace which adds a significant amount of weight, you will always see deflection and movement depending on power/traction. The system doesn't claim to eliminate it, it claims to reduce it, which it does really well. Just because you haven't seen it doesn't mean its wrong. Heres an example, I build a lot of machines with 80/20 framing, its all bolted together. A lot of the old timers look down on it and say weldments are the way to go because they wont ever come loose. There have been machines with reciprocating mass a lot linear motion and rotating mass. Not a single one has come loose in the past 15 years. The framing is nice because if you need to modify something its relatively easy where is in a weldment its a one shot deal and a PITA to fix it. Same principle applies here its a simpler method of achieving the same goal with some freedom in adjustability. To each their own I've been running this system and its not even the same car anymore, it handles and brakes leaps and bounds better than it ever did, i'm sure with a weldment under there it would perform better but for a street car Id be willing to bet the results would be negligible.

Similar threads

- Replies

- 3

- Views

- 562

- Replies

- 5

- Views

- 376