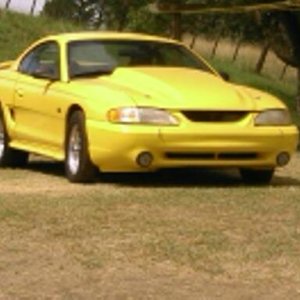

Hello! For those of you who follow the build, you know that I recently got a Tech Sponsorship with Setrab USA! For those who dont follow, now you know lol. So a bit of background, I have a 1994 GT that was a daily driver, now its going to be more track oriented (autocross and road racing). The car was working good, until about the first of this year, when during a canyon run, power steering fluid gushed all over the engine bay. After that, it was downhill from there. Event after event, problems with the pump running dry because of spilled fluid. Had to figure out how to keep the temps low. Tried turning on the oil cooler fans, had to turn off my car in between runs, and had to adjust my driving to the point where I wasnt even trying anymore. One last event, it ran dry, and that was the last of that event. You can see the videos below where the steering locked and prevented me from steering, went straight for the comes.

[video=youtube_share;7HjfA4eB9YQ]https://youtu.be/7HjfA4eB9YQ[/video]

Same video, but different time

[video=youtube_share;7HjfA4eB9YQ]https://youtu.be/7HjfA4eB9YQ[/video]

And another one, but luckily this one was at the end. But you can see how much I had to adjust, brake earlier, and adjust transitions.

[video=youtube_share;t535kCai6aY]https://youtu.be/t535kCai6aY[/video]

Overall, bad combo. In racing, heat is probably your #1 enemy/competitor. We didnt help the 23 year old power steering pump by mounting huge and sticky 275's up front, and beating it around the track for about a year straight. It was clear the pump did not want to work anymore. How do you solve the problem? First, you should get rid of that pump, and probably NOT go with an OEM replacement. But, many of us do not have fabrication skills, the time, or the money to do that. Even then, there is no guarantee that it will solve your issue. So what do we do? Just keep breaking pumps and hope we dont crash? There is a solution. Ladies and Gentlemen, I introduce you to the Setrab USA's Oil Cooler Fanpack (Part#FP113M22I). As many of you know, Setrab is a leader in the oil cooler industry, and is used by some brands as an OEM oil cooler. Is your diff oil overheating? Oil? What about your power steering fluid? Cooler is your solution. I wont bore you with the technical details of fluid, heat, blah blah blah. I will save that for the blog. However, I will be going over how to connect and install the cooler, as well as places to install, and reap its benefits. For now, enjoy some shitty pictures I took with my phone at work. Because I was too excited to wait till I got home.

[video=youtube_share;7HjfA4eB9YQ]https://youtu.be/7HjfA4eB9YQ[/video]

Same video, but different time

[video=youtube_share;7HjfA4eB9YQ]https://youtu.be/7HjfA4eB9YQ[/video]

And another one, but luckily this one was at the end. But you can see how much I had to adjust, brake earlier, and adjust transitions.

[video=youtube_share;t535kCai6aY]https://youtu.be/t535kCai6aY[/video]

Overall, bad combo. In racing, heat is probably your #1 enemy/competitor. We didnt help the 23 year old power steering pump by mounting huge and sticky 275's up front, and beating it around the track for about a year straight. It was clear the pump did not want to work anymore. How do you solve the problem? First, you should get rid of that pump, and probably NOT go with an OEM replacement. But, many of us do not have fabrication skills, the time, or the money to do that. Even then, there is no guarantee that it will solve your issue. So what do we do? Just keep breaking pumps and hope we dont crash? There is a solution. Ladies and Gentlemen, I introduce you to the Setrab USA's Oil Cooler Fanpack (Part#FP113M22I). As many of you know, Setrab is a leader in the oil cooler industry, and is used by some brands as an OEM oil cooler. Is your diff oil overheating? Oil? What about your power steering fluid? Cooler is your solution. I wont bore you with the technical details of fluid, heat, blah blah blah. I will save that for the blog. However, I will be going over how to connect and install the cooler, as well as places to install, and reap its benefits. For now, enjoy some shitty pictures I took with my phone at work. Because I was too excited to wait till I got home.