PRO5OHHO

New Member

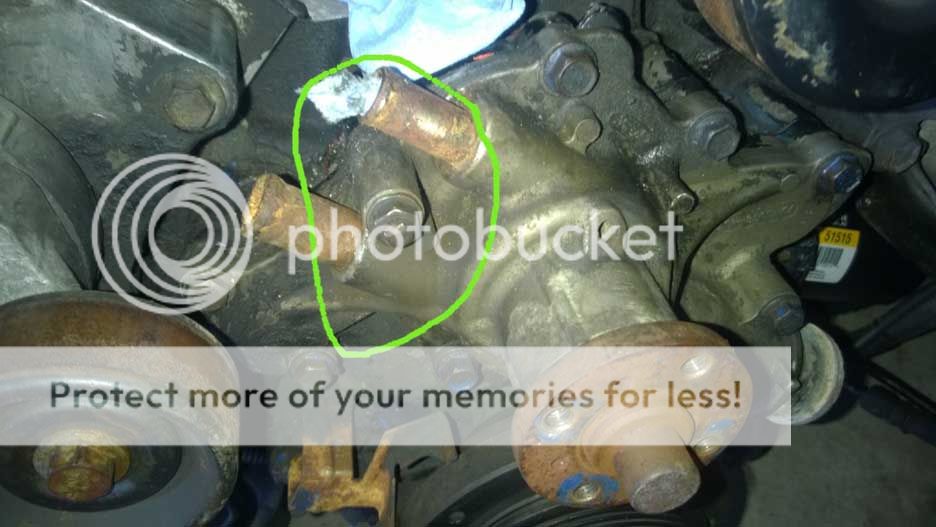

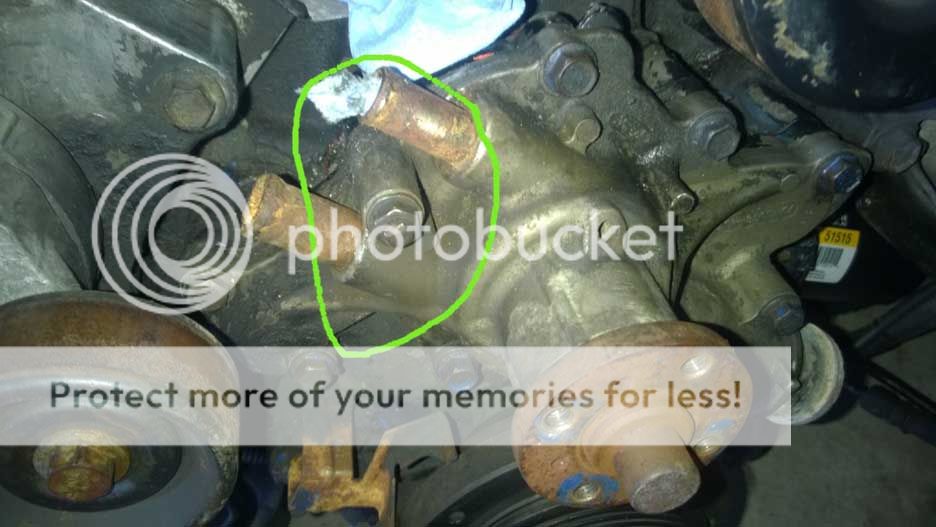

94 5.0L here. Trying to replace my water pump gasket, hasn't been off the car in 10 years. Bolts aren't giving me much resistance coming out, but the one stud right above the water pump is giving me problems. I've been applying about 15 lbs of force consistently to get it out, I've gotten it to back out about 3/8ths of an inch, but no matter how many more revolutions I make on the ratchet, it just keeps turning and turning and won't come out any further. At no point did it feel like I broke the stud off so I'm perplexed as to why it's just turning and not coming out. Is there another nut on the stud somewhere between where the stud goes from the block through the timing cover and then through the water pump? I don't see what's keeping the stud from coming out.

I know these things are notorious for breaking water pump bolts if you've put too much pressure on them, but I don't think it's broken. I've circled the stud in question in the picture.

I know these things are notorious for breaking water pump bolts if you've put too much pressure on them, but I don't think it's broken. I've circled the stud in question in the picture.