WHY

Why replace the bushings?

As anything in our cars, stuff wears out. Bushings are among the things that over time will distort and give less then ideal effects in handling, ride, and comfort. Some replace bushings to stiffen the ride and improve handling, some just want the stock quality ride restored. Getting into the front control arms (CA), stock bushings are adequate for street use. They dampen road noise and give a fairly cushy ride. Changing to polyurethane bushings gives you much more response, but the NVH (noise, vibration, harshness) is increased. This needs to be taken into account based on what you enjoy with your Mustang. The next step is delrin/aluminum which has very little deflection making it almost solid. NVH is at max with anything that stiff.

Stock control arms are adequate for everything you may want to do with your car. Aftermarket control arms can be purchased, they typicaly already have poly/delrin bushings installed and will be a direct swap. The aftermarket are usualy lighter, and have some wheel relocation which amounts to better handling charecteristic. The bushings I will be installing on my stock control arms are the Global West DEL-ALUM type that relocate the control arm forward of the stock location to increase front/rear track. If you choose to get an aftermarket CA, you obviously don't need to go through this surgery.

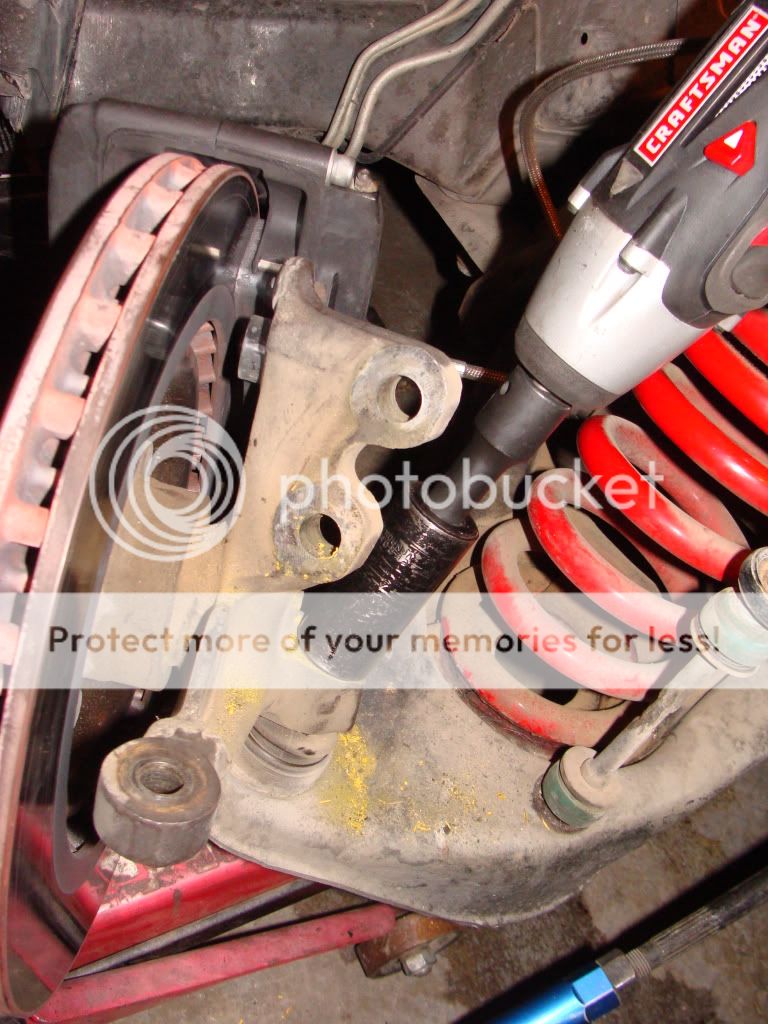

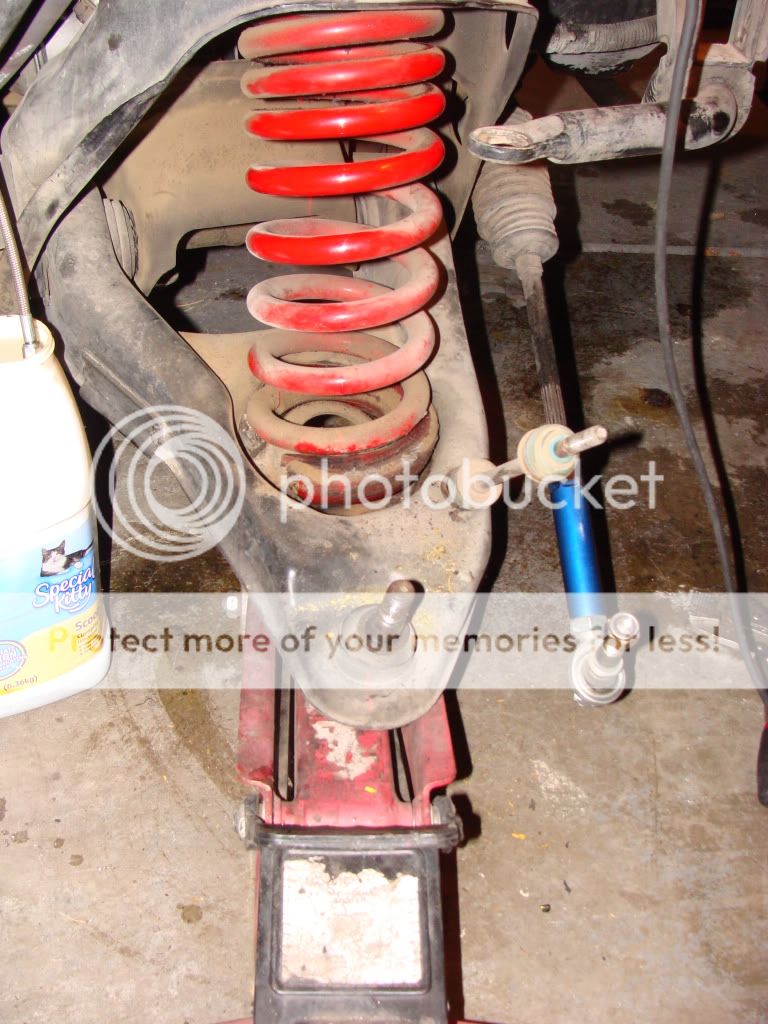

With worn out bushings you will get wheel movement as in the above diagram which is not desired. Specialy on a track car when maximum grip is needed.

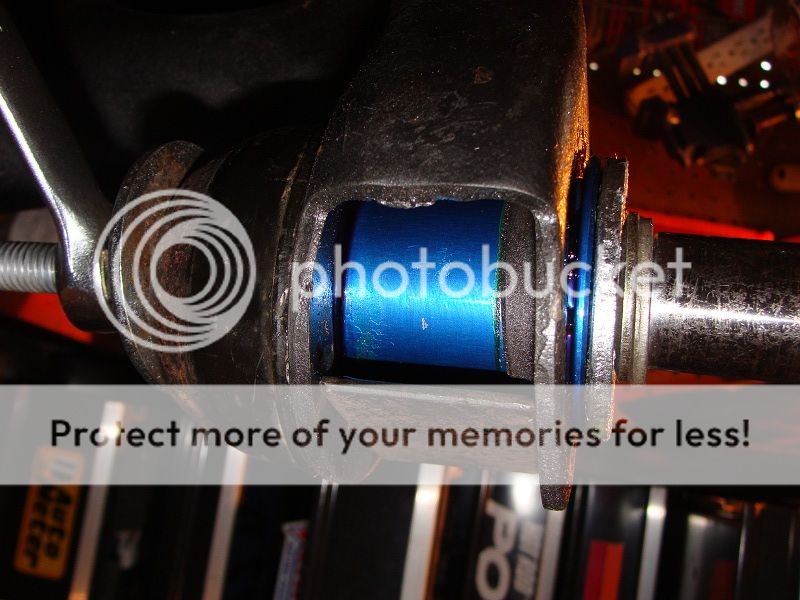

Examples of some worn/distorted bushings and the new del-alum bushings I'm putting in.

Why replace the bushings?

As anything in our cars, stuff wears out. Bushings are among the things that over time will distort and give less then ideal effects in handling, ride, and comfort. Some replace bushings to stiffen the ride and improve handling, some just want the stock quality ride restored. Getting into the front control arms (CA), stock bushings are adequate for street use. They dampen road noise and give a fairly cushy ride. Changing to polyurethane bushings gives you much more response, but the NVH (noise, vibration, harshness) is increased. This needs to be taken into account based on what you enjoy with your Mustang. The next step is delrin/aluminum which has very little deflection making it almost solid. NVH is at max with anything that stiff.

Stock control arms are adequate for everything you may want to do with your car. Aftermarket control arms can be purchased, they typicaly already have poly/delrin bushings installed and will be a direct swap. The aftermarket are usualy lighter, and have some wheel relocation which amounts to better handling charecteristic. The bushings I will be installing on my stock control arms are the Global West DEL-ALUM type that relocate the control arm forward of the stock location to increase front/rear track. If you choose to get an aftermarket CA, you obviously don't need to go through this surgery.

With worn out bushings you will get wheel movement as in the above diagram which is not desired. Specialy on a track car when maximum grip is needed.

Examples of some worn/distorted bushings and the new del-alum bushings I'm putting in.