MustangMatt96GT

Well-Known Member

- Joined

- May 29, 2007

- Messages

- 1,295

- Reaction score

- 6

Many people know that Weld racing Prostars or Draglites have a problem clearing the front brakes. Infact many drag wheels do that are skinny. Anyway i ran a spacer for about 6 months. I got sick and tired of it. Not to mention with the long shank lug nuts that the wheels require, the spacer then eats up about 3/8s of the threads. The more threads the better, and its a NHRA rule for the lug stud to come through at least half the nut part of the shank Lugs. Thus the reason I have 3 inch studs in the rears and i am in the process of putting the 3 inchers in the front too.

1. Jack up car and secure the car on jack stands. Take front wheels off.

2. Once wheels are off, you are all set to go at it. Go grab you hack saw. Start cutting off the bar that goes in front of the rotor.

3. Once the bar has been cut off, you now have to get an angle grinder and start grinding at the ends of the caliper bracket. You have to take quite a bit off.

4. Keep grinding off metal until you can get your wheel on there with out any rubbing. I took mine down quite a ways.

5. Once you have it so it can clear. Take some Hitemp paint and paint them the color you want. This makes it so they wont rust.

6. Put the wheels back on and lower the car. Now take it for a drive to make sure with the extra weight of the car, there isnt any rubbing.

Here is a picture of mine off of the car, because of the stud change.

Here it is on the other side on the car.

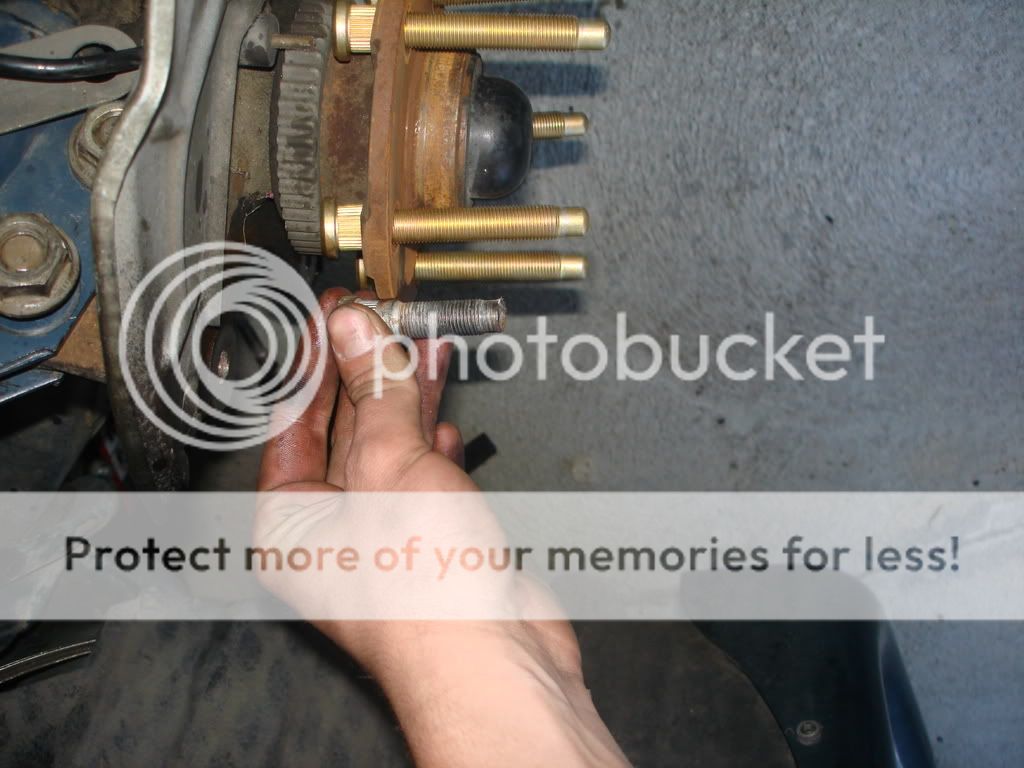

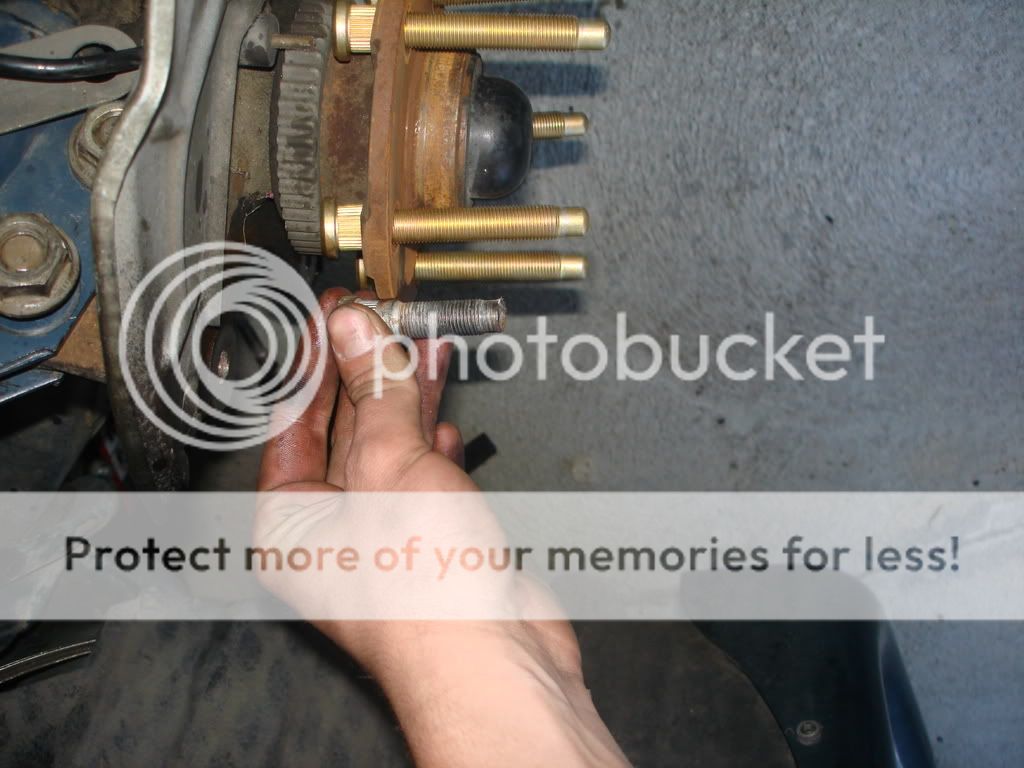

and here is the length difference between the stock lug studs and the ARP 3 inchers.

1. Jack up car and secure the car on jack stands. Take front wheels off.

2. Once wheels are off, you are all set to go at it. Go grab you hack saw. Start cutting off the bar that goes in front of the rotor.

3. Once the bar has been cut off, you now have to get an angle grinder and start grinding at the ends of the caliper bracket. You have to take quite a bit off.

4. Keep grinding off metal until you can get your wheel on there with out any rubbing. I took mine down quite a ways.

5. Once you have it so it can clear. Take some Hitemp paint and paint them the color you want. This makes it so they wont rust.

6. Put the wheels back on and lower the car. Now take it for a drive to make sure with the extra weight of the car, there isnt any rubbing.

Here is a picture of mine off of the car, because of the stud change.

Here it is on the other side on the car.

and here is the length difference between the stock lug studs and the ARP 3 inchers.