Re: Paul's '89 Notch Build - Updated 01/19/09

I've been doing a bunch of work to the interior lately. I'm going to replace the old beat up porno red interior with black. First things first, I needed to get the old interior out... and so it began.

Here's the old center cluster from when I bought the car.

A local stereo guy volunteered to come remove all the "mystery wires" from under the dash since I suck at electrical. This is what he pulled out. None of it did anything.

This last weekend I started tearing the interior out wholesale.

I had to get the steering wheel off, but once you get the cruise switches and trim off, it's just one bolt.

Then a few quick turns of the steering wheel puller and it pops right off.

The cruise control switches and clockspring thingy were set aside for another project that I'll show you guys later. It will be pretty cool and you guys will like it. :grin:

Another friend of mine gave me a good working '87-'89 tilt column too. The tilt mechanism in my old one was screwed up, and it would "tilt" without pulling the tilt lever. It was annoying at best, and dangerous at worst. Another buddy actually gave me a '90-'93 non-tilt airbag column too, but since I was able to source a tilt column I didn't use it. I gave it away to another friend of mine. The one on the left is non-tilt from 90-93, and the two on the right are 87-89 non-airbag tilt columns.

After quite a bit of work, I got the old column and dash completely out of the car.

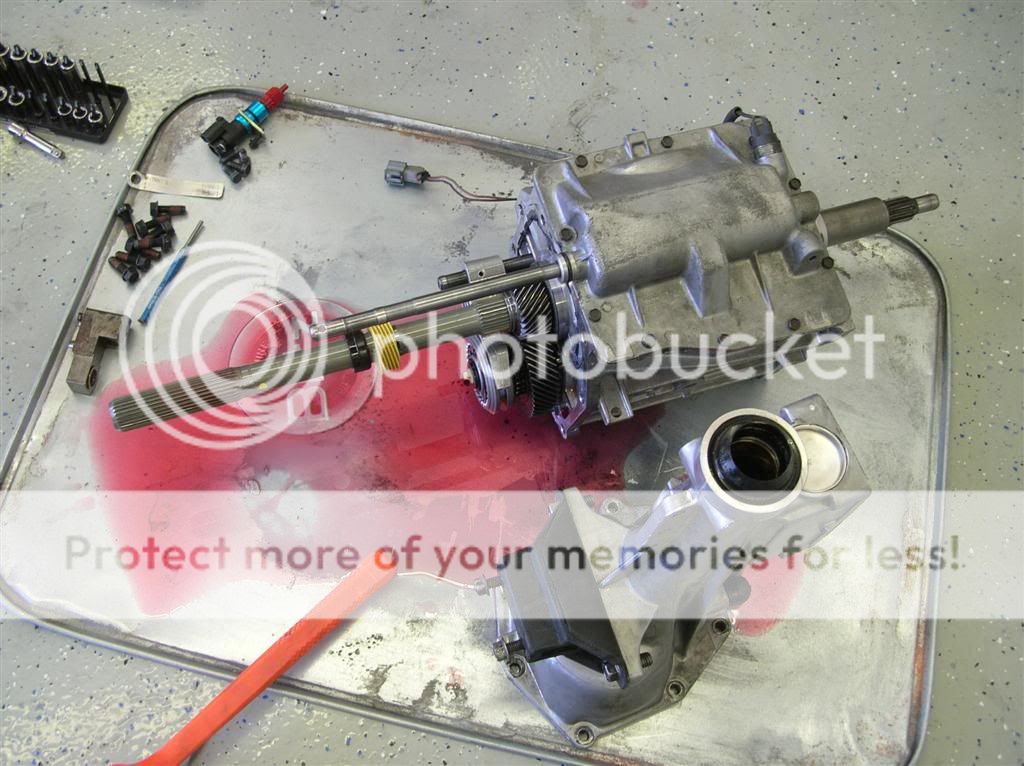

I figured I would replace the heater core while I was at it since I was this far into it anyway. When I dropped the A/C box down to access the heater core, I found this giant crack in the box. A friend of mine works at a Ford dealership, and showed it to one of their techs. Apparently if the dealer needs to replace the A/C condenser, they just slice the top of the box open, pull out the old condenser, stick a new one in, and glue it back up. Well you can see how well it held up. :BangHead:

I hate half-assed jobs, so I decided to completely remove the entire A/C box and rebuild it... Out came the box.

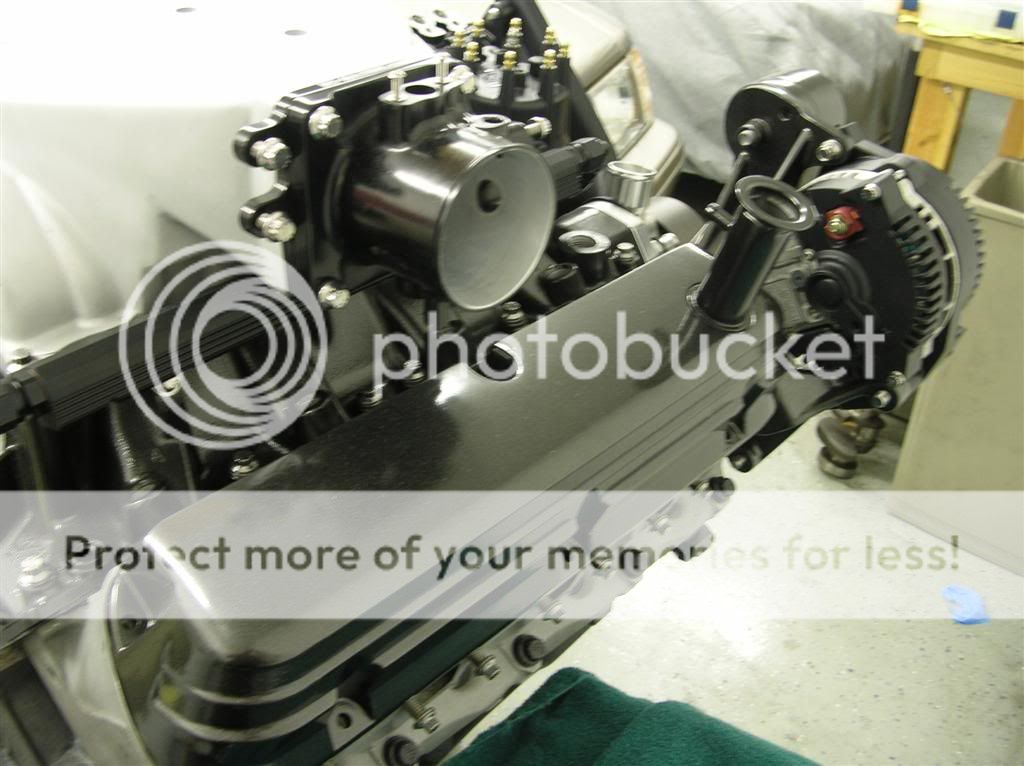

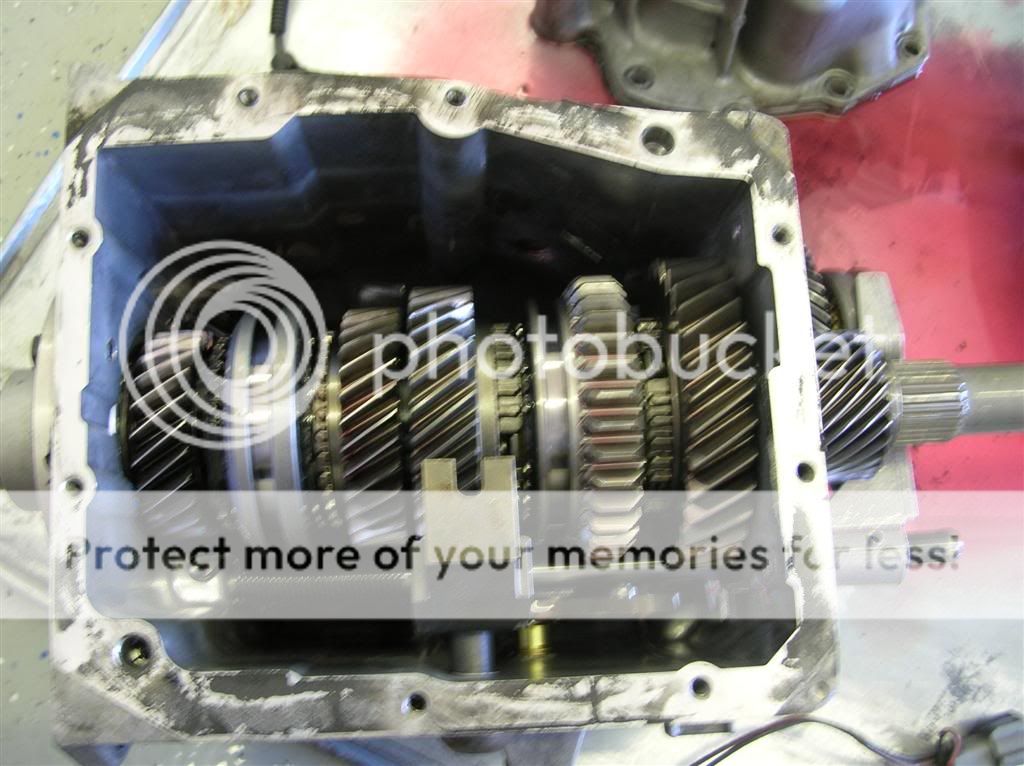

A friend of mine is really knowledgable about this stuff, so he offered to come over and show me what's involved. Another friend of mine gave me a complete spare A/C box out of another '89, which we used for parts. We took the whole box apart.

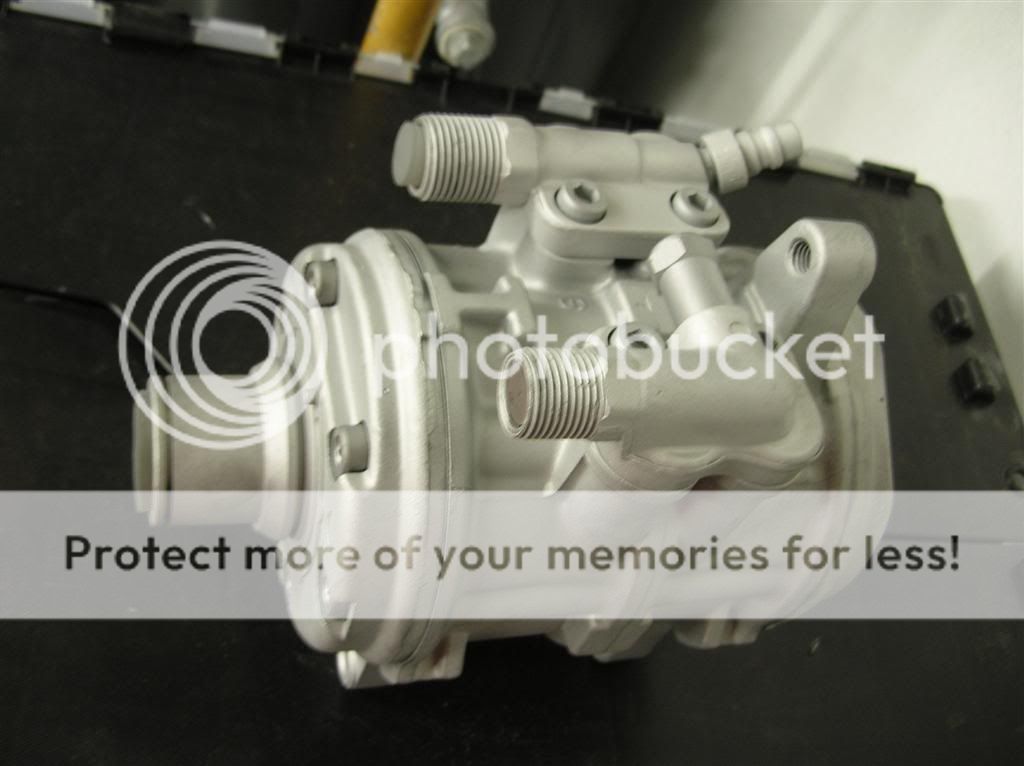

This is the blower motor:

In the foreground of this picture you can see the condenser core. We cleaned it all out and tested for leaks. There was a ton of leaves and gunk in it. Gross.

Here you can see my friend Richard putting silicone on top of box where the lid for the heater core goes. You'll also notice the new box doesn't have a giant crack in it. :tongue3:

ABS cement was used to fuse the various parts of the box back together. You can see some vicegrips holding the parts together while the cement bonded. We also put screws in a couple places where it didn't quite go back together perfectly.

The new heater core was dropped into place, and he's about to put the lid back on.

And tah dah! One brand-new-20-year-old A/C box. :tongue3:

I actually had an original (and very hard to find) black dash that my friend Rob gave to me. Unfortunately, I can't use it because it's for a 90-93 car. They have a slightly different fuse box setup and other small differences. Here's a pic of my red and black dashes.

Luckily I also had an old grey dash that has been sitting in my side yard in the sun for 1.5 years. Amazingly, it cleaned up pretty well with some soap and water, and a bit of scrubbing. This dash was prepped and painted black later that day.

I disassembled all the A/C vents, cleaned, and painted them.

I actually reinstalled the A/C box and new black dash last Saturday, but for some reason I didn't take any pictures. I think it was because it was late, I was tired, and probably grumpy. I'll get some pics up soon hopefully.

More to come...

Paul.