Burninriverdiver

Well-Known Member

- Joined

- Jan 1, 2014

- Messages

- 2,770

- Reaction score

- 234

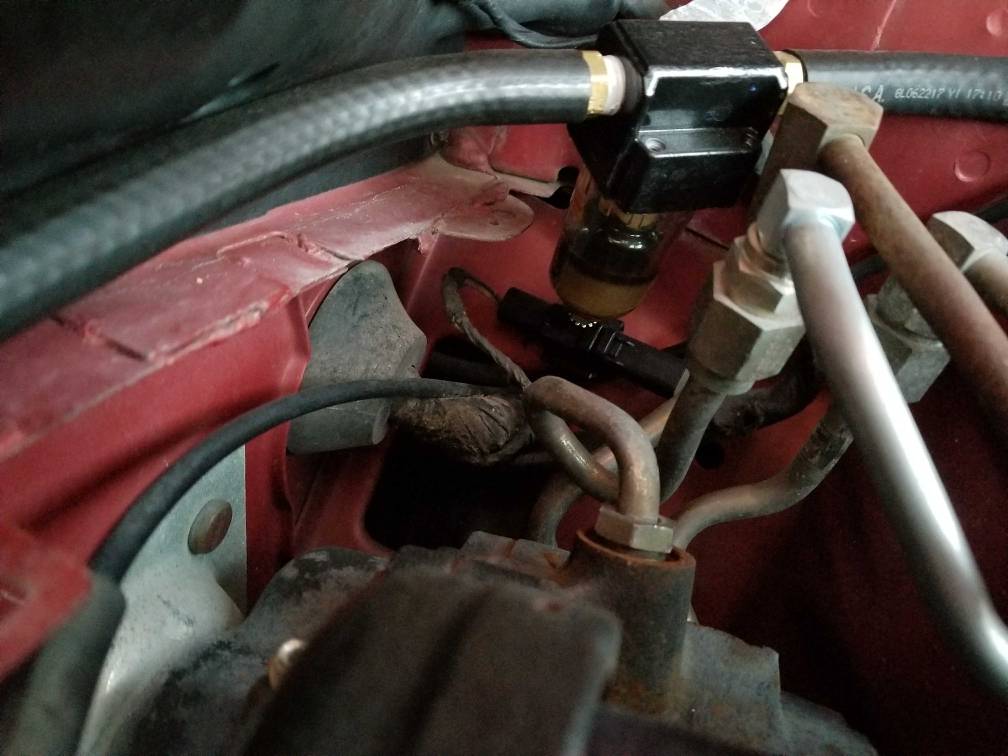

Every time I need to work on the top end of my motor the hard plastic lines are in the way and need removed. After 22 years of heat exposure these things crack in a new place every time I breathe too hard. I got tired of patching them so I came up with a solution.

You will need:

1: Old cracked vacuum lines with the rubber connectors. I reused the rubber connectors since they were in good shape.

2: Approximately 10 feet of 3/16 hard brake lines (I chose the nickel/copper for ease of bending and flaring... not to mention bling)

3: Approximately 2 feet of 5/32 rubber hose (washer fluid line hose was what I used).

4: Heat shrink wrap (3/16 inner diameter) for the ends of the plastic lines to ensure a tighter seal against the rubber hose.

TOOLS

4: Flaring tool to ensure a seal is created between the rubber and copper lines.

5: Tubing cutter

6: (Optional) tube bender. I bent mine by hand, it's easy with the nickel/ copper lines. I can't find my tube bender so I decided to bend by hand; the bender would help to make a cleaner install.

Onto the action.

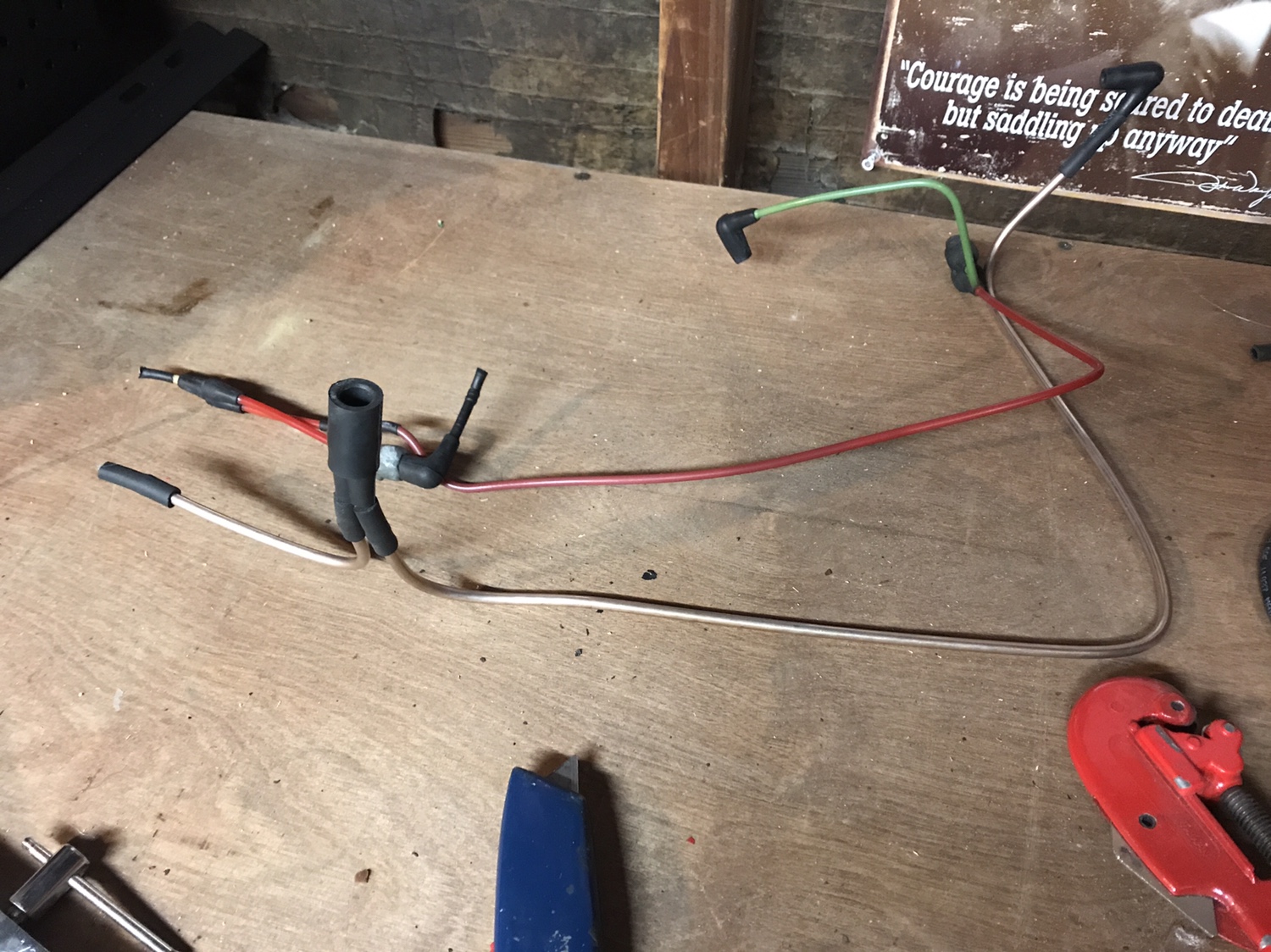

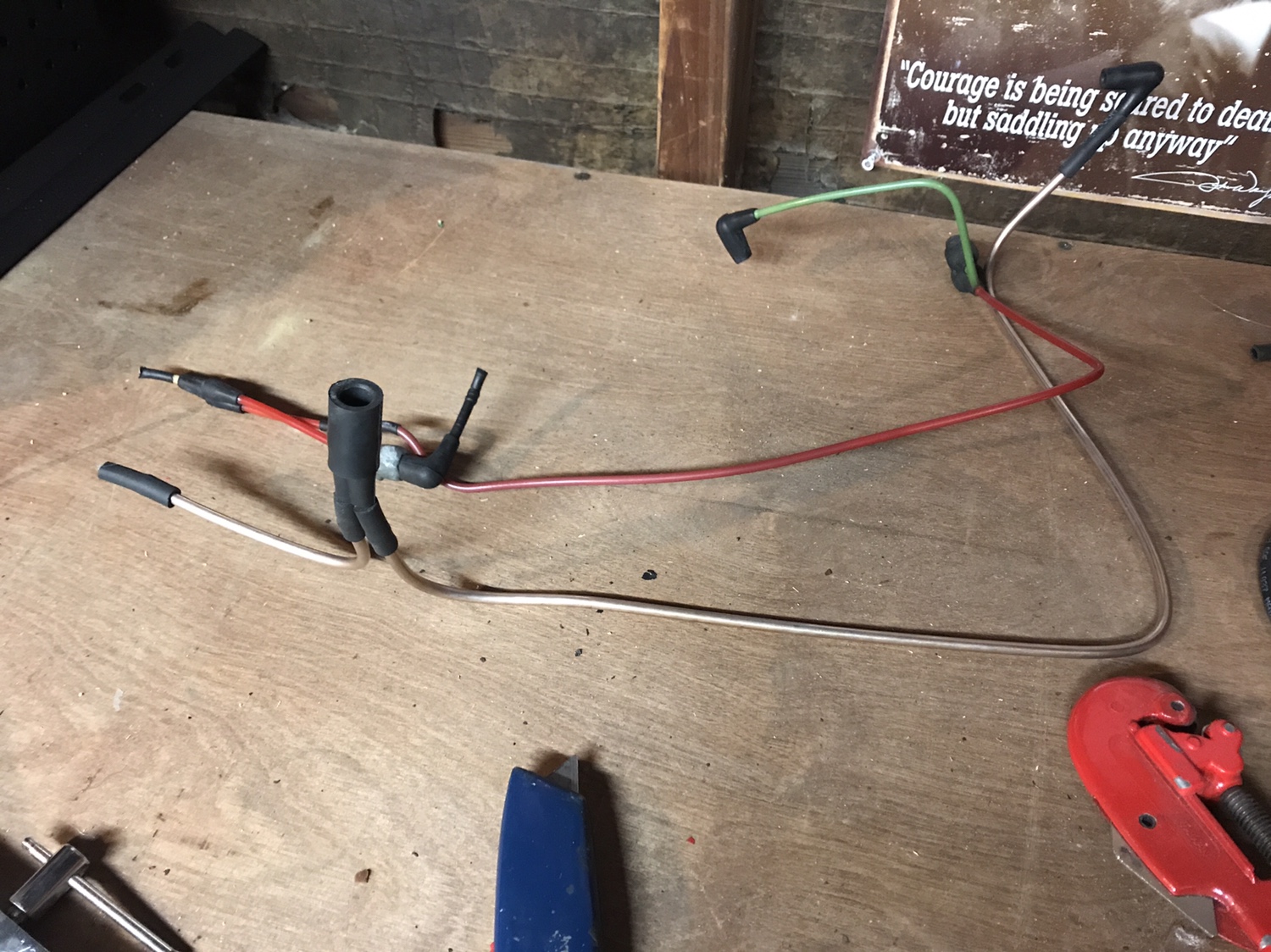

1st: Remove the plastic lines from all the vacuum connections and pull it out in one piece if possible. After removal place the piece on a work bench for reference.

2nd: Cut the dual connector that goes into the throttle body, leaving enough plastic hard line to slip your washer fluid hose over (1" will do).

3rd: Measure the cut portions of the hard plastic lines that are going to be replaced with copper lines. Cut the copper lines to that length.

4th: Flare the end of each new copper line so it makes a better seal with the rubber tubing that it will connect to.

5th: Apply the heat shrink wrap over the exposed plastic hard lines that go into the factory rubber connector. The heat shrink wrap increases the outer diameter of the hard plastic line stubs and makes a better seal to the rubber washer fluid line. (Photo in the 2nd step shows my heat shrink wrap already in place to patch cracks from previous removal).

6th: Slide rubber hose over copper line and then over the hard line stub that goes into the factory rubber connector.

7th: Continue to measure and replace each hard plastic line with copper lines in the same manner while bending each to match the factory pathway. I apologize for not getting measurements or angles of each line, I may update in the future.

8th: Put into place and fine tune the bends as needed. Copper lines are easier to make hairpin adjustments by hand than steel/ stainless.

That's it. I have some valve seals to replace so I didn't bother installing fully because I'd have to remove it when my spring compressor comes in anyway.

This thread is open to better installation techniques and suggestions. I haven't tested it out running yet but I have full confidence that it will work better than the cracked and dry rotted plastic hard lines that were on it.

Sent from my iPhone using Tapatalk

You will need:

1: Old cracked vacuum lines with the rubber connectors. I reused the rubber connectors since they were in good shape.

2: Approximately 10 feet of 3/16 hard brake lines (I chose the nickel/copper for ease of bending and flaring... not to mention bling)

3: Approximately 2 feet of 5/32 rubber hose (washer fluid line hose was what I used).

4: Heat shrink wrap (3/16 inner diameter) for the ends of the plastic lines to ensure a tighter seal against the rubber hose.

TOOLS

4: Flaring tool to ensure a seal is created between the rubber and copper lines.

5: Tubing cutter

6: (Optional) tube bender. I bent mine by hand, it's easy with the nickel/ copper lines. I can't find my tube bender so I decided to bend by hand; the bender would help to make a cleaner install.

Onto the action.

1st: Remove the plastic lines from all the vacuum connections and pull it out in one piece if possible. After removal place the piece on a work bench for reference.

2nd: Cut the dual connector that goes into the throttle body, leaving enough plastic hard line to slip your washer fluid hose over (1" will do).

3rd: Measure the cut portions of the hard plastic lines that are going to be replaced with copper lines. Cut the copper lines to that length.

4th: Flare the end of each new copper line so it makes a better seal with the rubber tubing that it will connect to.

5th: Apply the heat shrink wrap over the exposed plastic hard lines that go into the factory rubber connector. The heat shrink wrap increases the outer diameter of the hard plastic line stubs and makes a better seal to the rubber washer fluid line. (Photo in the 2nd step shows my heat shrink wrap already in place to patch cracks from previous removal).

6th: Slide rubber hose over copper line and then over the hard line stub that goes into the factory rubber connector.

7th: Continue to measure and replace each hard plastic line with copper lines in the same manner while bending each to match the factory pathway. I apologize for not getting measurements or angles of each line, I may update in the future.

8th: Put into place and fine tune the bends as needed. Copper lines are easier to make hairpin adjustments by hand than steel/ stainless.

That's it. I have some valve seals to replace so I didn't bother installing fully because I'd have to remove it when my spring compressor comes in anyway.

This thread is open to better installation techniques and suggestions. I haven't tested it out running yet but I have full confidence that it will work better than the cracked and dry rotted plastic hard lines that were on it.

Sent from my iPhone using Tapatalk