Hey guys!

I recently picked up my second mustang! That thing is a beauty,1995, triple black 5.0L! I bought it from the second owner and it only have 75k miles on it. Its pretty much stock except a BBK cold air intake and 17'' Cobra wheel.

Now a week after i bought the mustang i saw an add on facebook marketplace for a quickjack 5000lbs that is pretty much new. I jumped on it since i now have my own house and garage to work on the mustang. and i already have dome parts to install.

I then looked online for some tips on where to lift the mustang with a quickjack and found pretty much nothing. My car does not have frame connector, and i know that LMR sells a pinch weld jack plate for mustang but in the video that showcase the product it is said that you cannot lift the sn95 convertible by the pinch weld. So i'm confused as if i can really use my quickjack with it?.

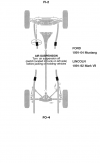

I know that if i need to work on the front wheel/suspension, i can lift the front with a jack under the k-member and put jackstand under the front of the frame rail, and in the back i can lift the car by the diff and put jackstand on the axle tube. But if i need to lift the rear leaving the axle tube free for like a control arm swap or spring swap, where the hell do you put jackstand? Directly under the flat part of the torquebox with maybe a piece of wood to spread the weight on it?

So basically is my purchase of a quickjack is useless? I dont really care if yes it is because these sells pretty well and for the price i paid i'm pretty sure i can sell it for the same if not a little more. But i would like to use it but in the correct way!

Am i over thinking this? I Just went on cars and bids, its a car auction site and usually people put a lot of pictures, and checked every auction of convertible sn95 and i saw that a lot of them had picture taken on lift and they were all using the pinch weld.

Thanks a lot!

I recently picked up my second mustang! That thing is a beauty,1995, triple black 5.0L! I bought it from the second owner and it only have 75k miles on it. Its pretty much stock except a BBK cold air intake and 17'' Cobra wheel.

Now a week after i bought the mustang i saw an add on facebook marketplace for a quickjack 5000lbs that is pretty much new. I jumped on it since i now have my own house and garage to work on the mustang. and i already have dome parts to install.

I then looked online for some tips on where to lift the mustang with a quickjack and found pretty much nothing. My car does not have frame connector, and i know that LMR sells a pinch weld jack plate for mustang but in the video that showcase the product it is said that you cannot lift the sn95 convertible by the pinch weld. So i'm confused as if i can really use my quickjack with it?.

I know that if i need to work on the front wheel/suspension, i can lift the front with a jack under the k-member and put jackstand under the front of the frame rail, and in the back i can lift the car by the diff and put jackstand on the axle tube. But if i need to lift the rear leaving the axle tube free for like a control arm swap or spring swap, where the hell do you put jackstand? Directly under the flat part of the torquebox with maybe a piece of wood to spread the weight on it?

So basically is my purchase of a quickjack is useless? I dont really care if yes it is because these sells pretty well and for the price i paid i'm pretty sure i can sell it for the same if not a little more. But i would like to use it but in the correct way!

Am i over thinking this? I Just went on cars and bids, its a car auction site and usually people put a lot of pictures, and checked every auction of convertible sn95 and i saw that a lot of them had picture taken on lift and they were all using the pinch weld.

Thanks a lot!

Last edited: