AfghaniBob

Member

- Joined

- Jun 19, 2007

- Messages

- 130

- Reaction score

- 20

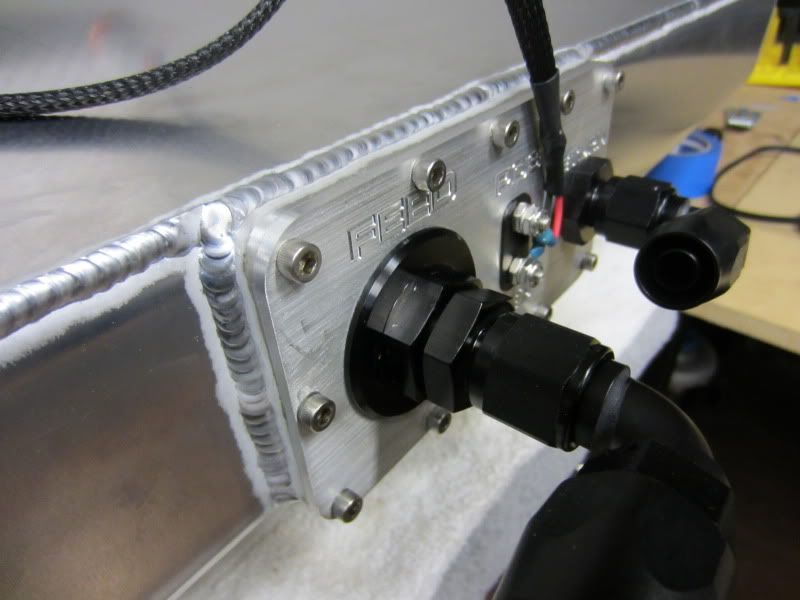

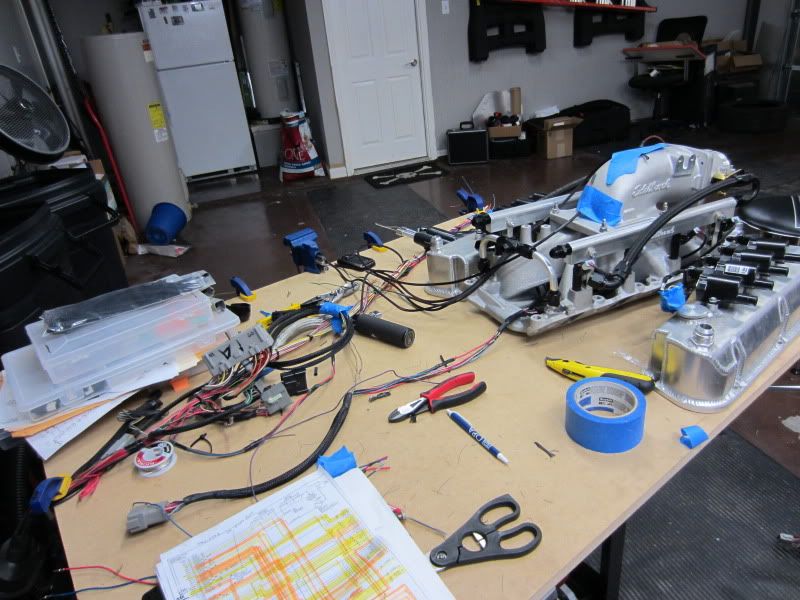

From building the hoses

Update:

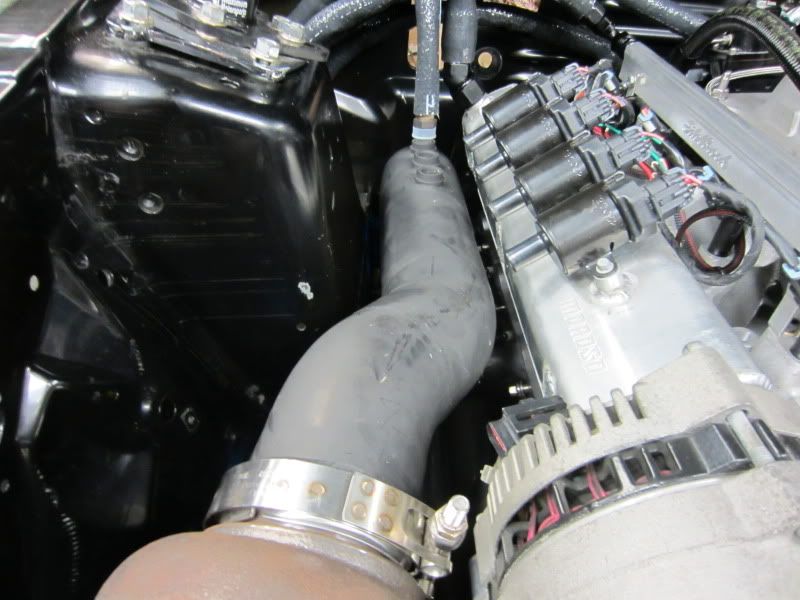

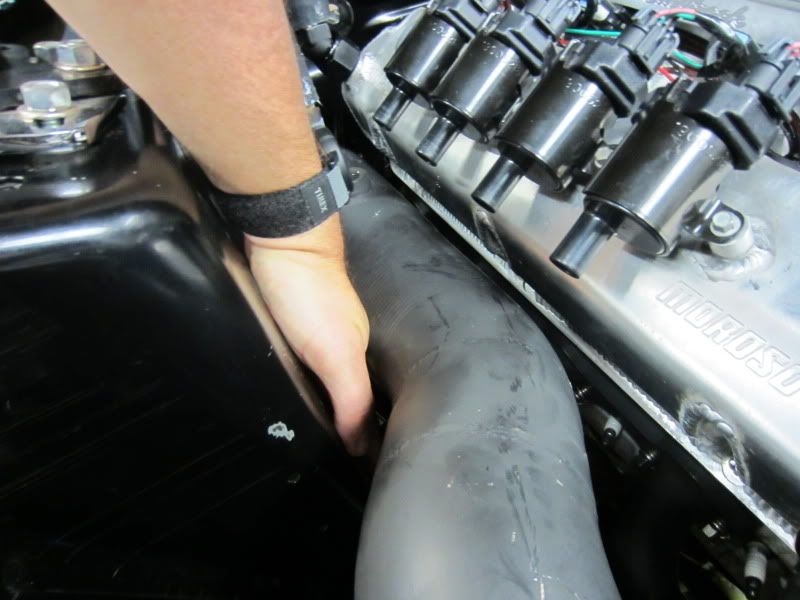

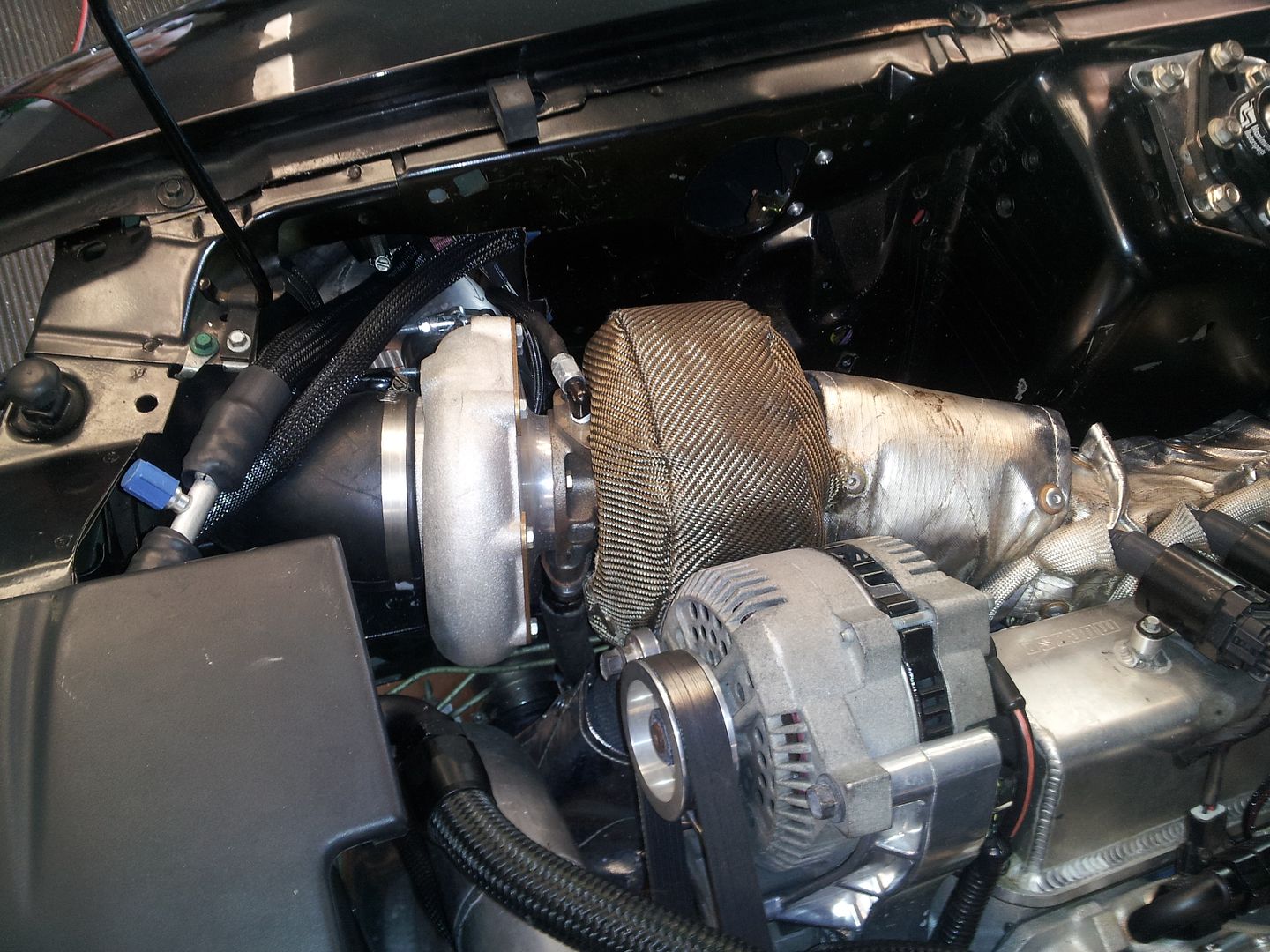

Hoses came back from Kim's in Fort Worth and his brazing aluminum tubes to the unique ends the condenser required look factory and perfect. Since I marked the "clock" of the fittings/hose they installed in a matter of minutes.

I used a unused hose end to the compressor with a section of hose on it to fill the compressor. Compressor got about 5oz and the accumulator got a little over 3oz. I cranked it at least 20 times. All the fittings are tight and the lines are protected from abrasion and secured.

Take a look at how good the welded ends for the condenser came out. It took a little thought but I am confident I could have used any style of condenser/accumulator/etc and made it all work just the same.

Welded end

after

Welded end from 3 pieces

before

after

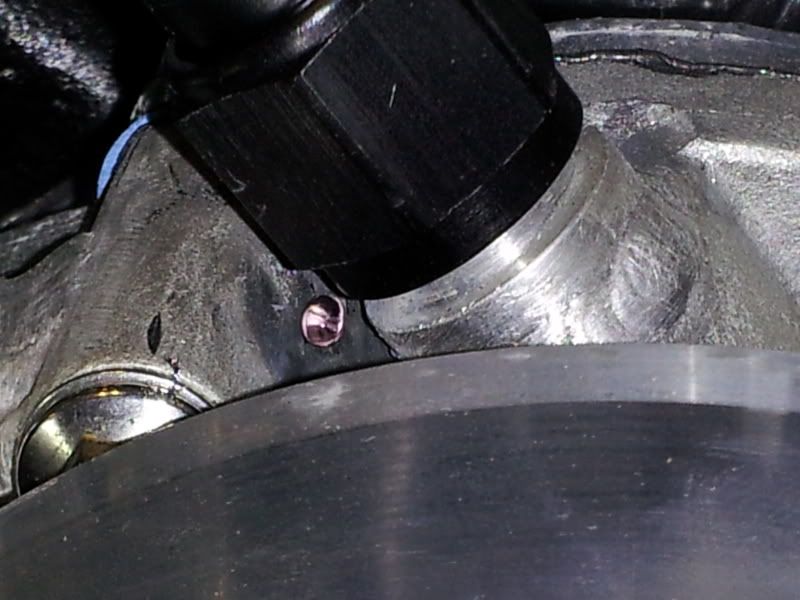

Pressure switch spliced in

Line

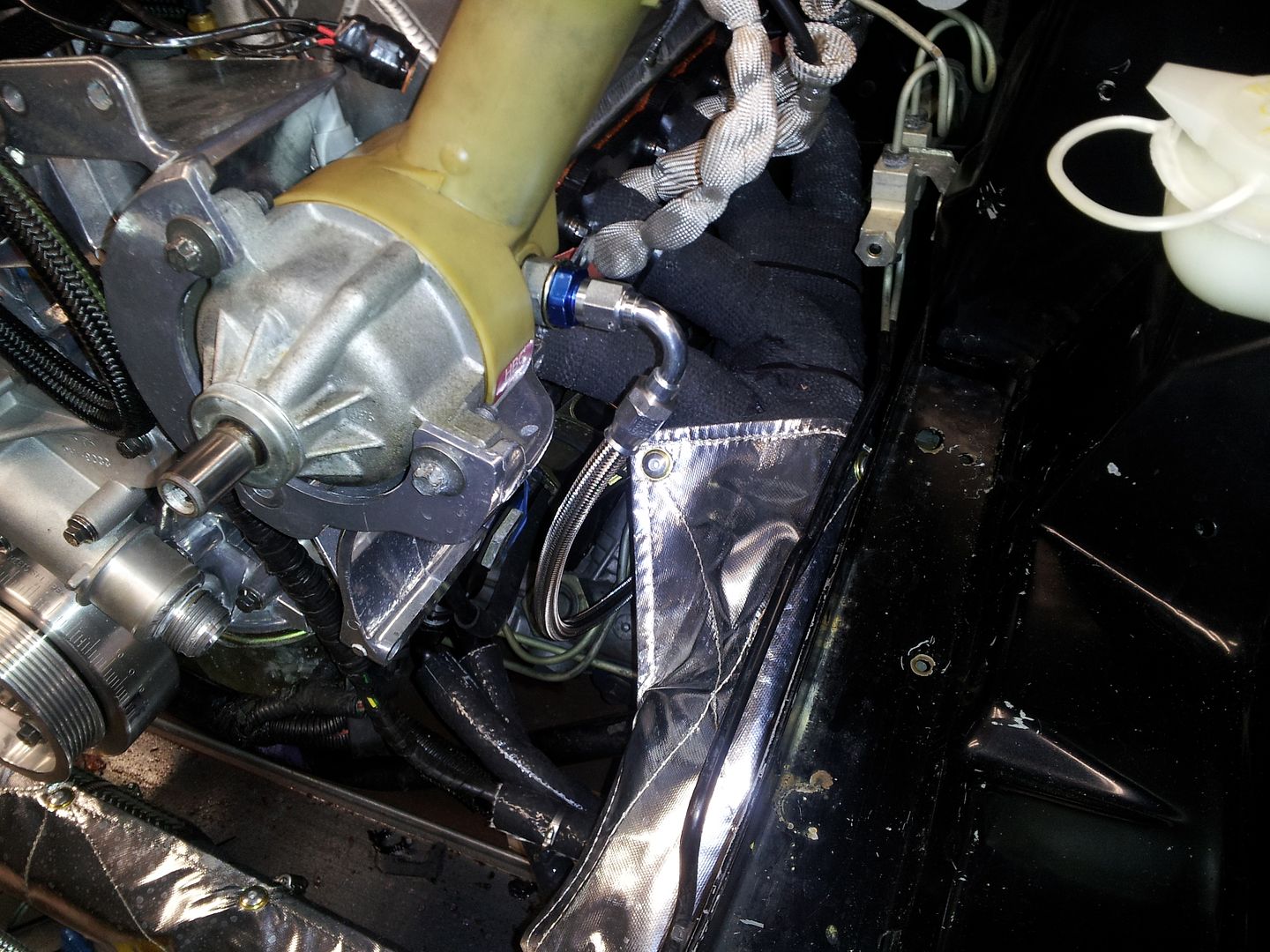

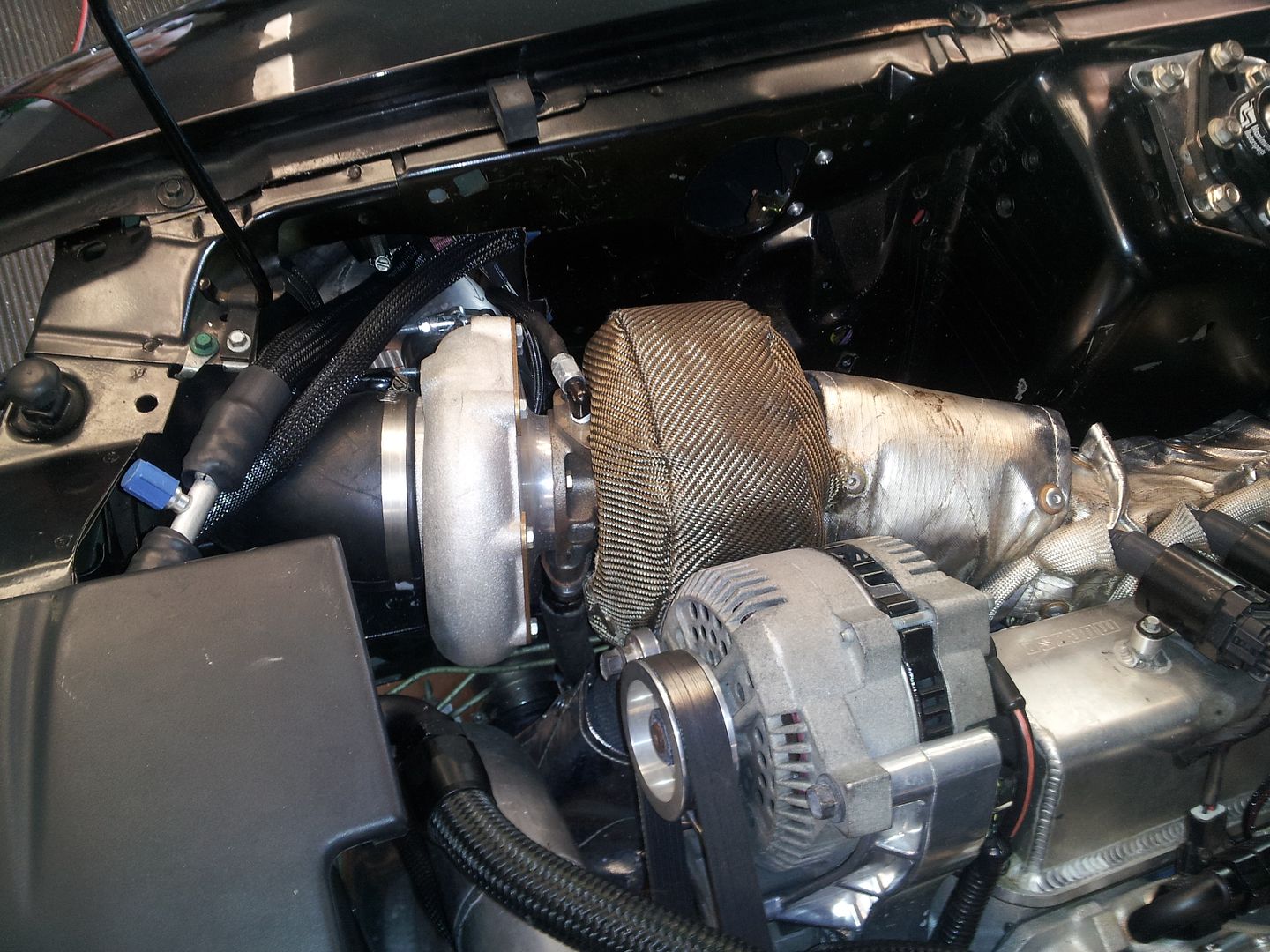

What you see

To the evaporator

Update:

Hoses came back from Kim's in Fort Worth and his brazing aluminum tubes to the unique ends the condenser required look factory and perfect. Since I marked the "clock" of the fittings/hose they installed in a matter of minutes.

I used a unused hose end to the compressor with a section of hose on it to fill the compressor. Compressor got about 5oz and the accumulator got a little over 3oz. I cranked it at least 20 times. All the fittings are tight and the lines are protected from abrasion and secured.

Take a look at how good the welded ends for the condenser came out. It took a little thought but I am confident I could have used any style of condenser/accumulator/etc and made it all work just the same.

Welded end

after

Welded end from 3 pieces

before

after

Pressure switch spliced in

Line

What you see

To the evaporator