You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project Unfinished Business: 95PGTTech's 1998 Cobra build...

- Thread starter 95PGTTech

- Start date

Chris: yep, MIG ground cable.

No. Most are an hour install welding from the bottom of the car. This is above and beyond the amount of work for even most through-floor installations. The advantages of this method are far increased rigidity and ground clearance; the disadvantage is a lot more difficult install. Cost ends up being about the same if you're doing the install yourself; cost to do through-floors is way higher if you're paying someone to do it for you.

Xronin said:ok school me if im just being dumb but is that how all sub fram connectors go in ??? cutting through the floor and welding em in ?

No. Most are an hour install welding from the bottom of the car. This is above and beyond the amount of work for even most through-floor installations. The advantages of this method are far increased rigidity and ground clearance; the disadvantage is a lot more difficult install. Cost ends up being about the same if you're doing the install yourself; cost to do through-floors is way higher if you're paying someone to do it for you.

thanks for the info.

also, your bandwidth is exceeded...

also, your bandwidth is exceeded...

Photobucket PWNED.

Now that I have a "PRO" photobucket account, one of the many treats is being able to upload in high resolution. I still picked 800x600 because that is still what the majority of people displays are set at and most forum rules, but is there any noticeable difference to you guys? I'm still shooting with the Canon Powershot A480 - I'm not bringing the 450D any more for car stuff it gets too dirty and paying to get it cleaned sucks.

New toys. The day my tools arrived from Summit someone put nearly the same exact stuff up on Corral used, and also the clutch. He cut me such a great deal overall that it makes sense for me to return the Summit stuff. I only eat the shipping within the first 60 days no restocking fee.

My cordless sawzall also arrived but I did not take a picture of it. According to the slip on my door, my cordless impact gun is also here. I stopped by Harbor Freight as I found the receipt for the second drill and attempted to return it, this time I just wanted store credit. Apparently, the 30 day warranty only extends to the first item, not to any replacement items. Humph. I'll stick to buying consumables from them and nothing else.

I got the driveshaft done at work this week in some spare time.

And the brake caliper brackets.

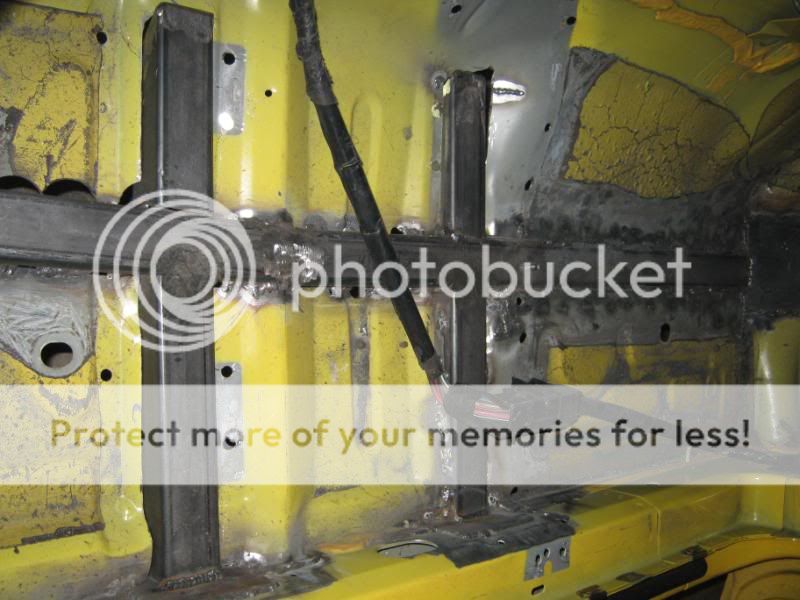

Upon arriving at the garage, I verified that the chassis, and then the front tube is level both vertically and horizontally for the 128,228,573rd time.

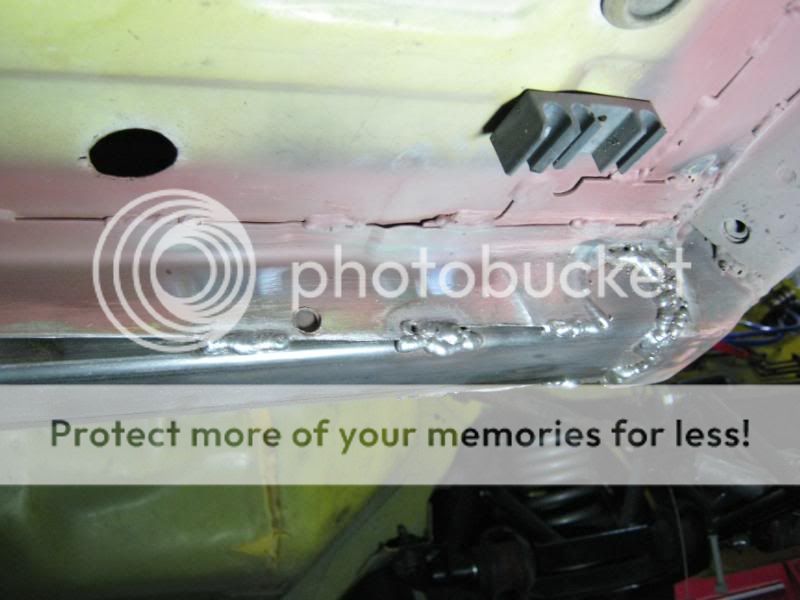

Slid under and welded the front of the front tube. Welded the underside of the tube to what remains of the channel.

Then cut and welded in the firewall footer plate. 4x6. Pretty thick sheetmetal along the bottom and sides but thin up top, watch it.

16.5" center section.

Cut the floorpan, angled both ends.

Tacked it in checking level in both directions.

Finish welded it, as well as the floorpan to it.

Of note, the weld where the center section meets the front section. A triple pass to ensure I got good penetration. This weld lands directly in the middle of where the seat would mount and in an effort to get the seat as low as possible and have as much clearance as possible this weld will be ground down. Therefore the overkill.

Front section welded to floorpan.

At this point, the sacrificial bracket can be removed and the rest of the front section bottom welded to the tunnel.

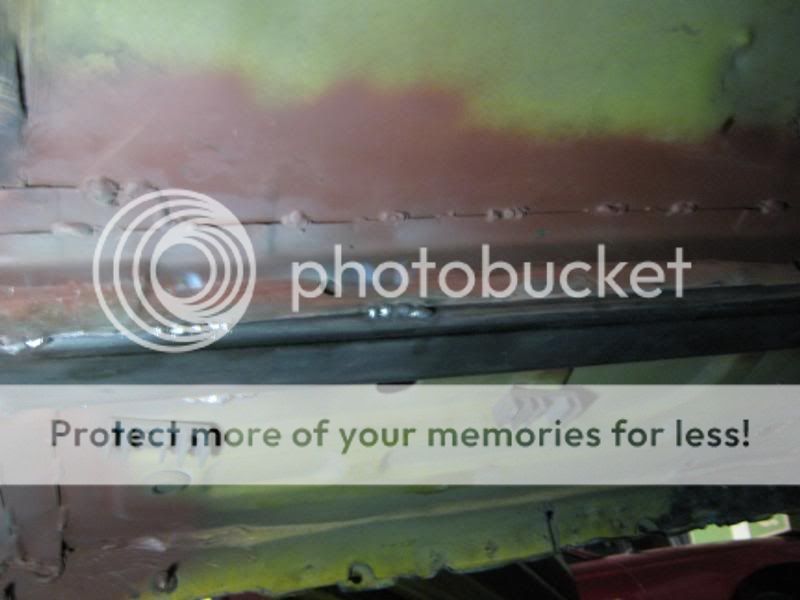

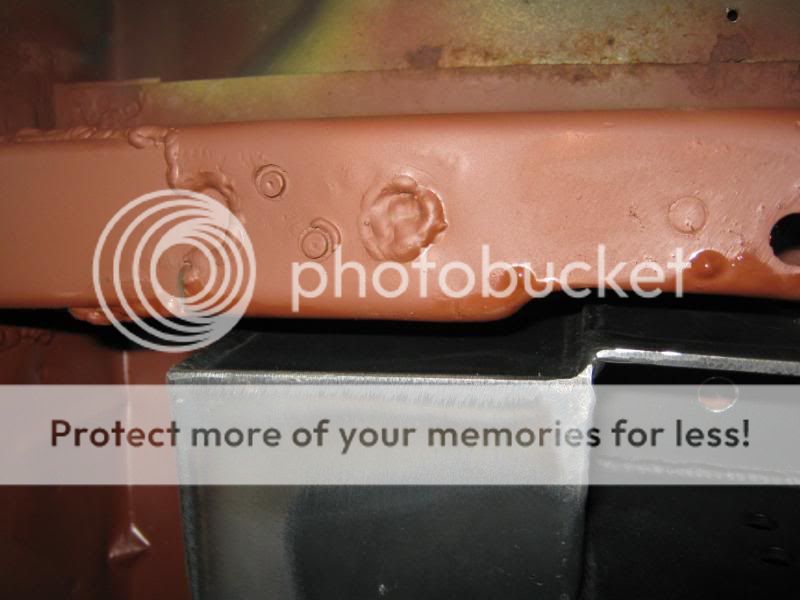

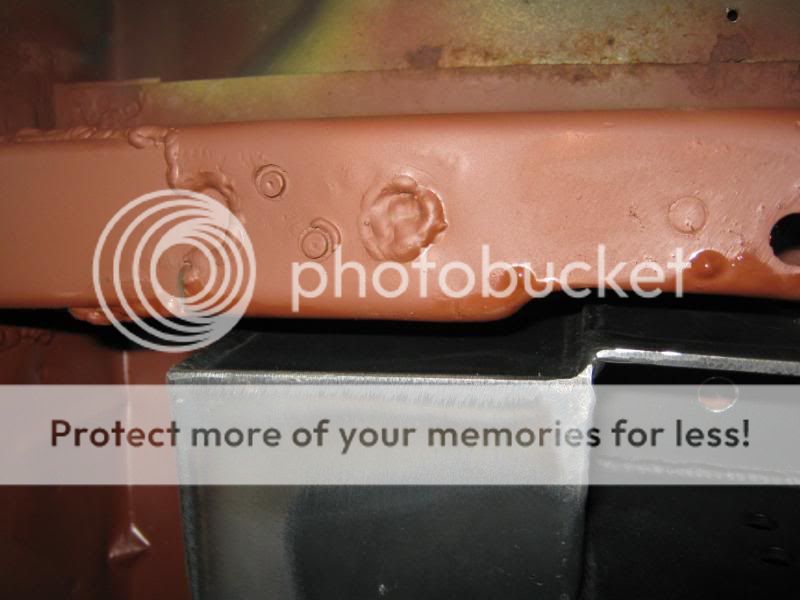

The replacement 4x4 seat mount/rocker footer plates installed. Much grinding/hammer/vicegrip was needed on my mangled pinch welds.

I wanted to start cutting the seat mount rails but I was running low on time and on argon. I wanted to finish off the tank so I could take it with me and pick up more on my way to the garage tomorrow since it's 5 minutes from my house and an hour from the garage. So I just finished 90% of the rest of the welding of the SFC to the floorpan, being careful not to weld the areas where the seat rails still needed to go and causing myself more work.

There were some serious gaps in areas and it's hard to figure out how to go from wanting good penetration (hot, high settings) of the .125" thick tube and not blowing through the thin 18 gauge floorpans (typically slow, low settings). I found it best to start welding only on the tube and use multi-pass welds to create a shelf to extend almost touching the floorpans on the highest settings (think creating a bridge one plank at a time). Then turn it way down and use a series of tacks to bridge the last small plank to the sheetmetal so it did not burn through. I welded both top and bottom from the same points. Once the bridge was created on one side, it was pretty easy on the other side to just leave it turned up since the welds are very thick and would not blow through.

I fixed the welder earlier in the day. I have been questioning myself lately if I need more classes I could not figure out where all this spatter and rough welds that stand way up are coming from. It turns out I had the feeder set way wrong, causing intermittent flow of wire, therefore spattering, therefore BBs and jams, and therefore poor heat/poor penetration/poor laydown/standup. Another interesting thing I noted was that in my rush, and emboldened by my now insanely hotter welds I blew right through the paint that remained on some of the rear floorpans and it made little difference. I simply used a little bit hotter setting than I normally would with very slow handspeed...the intense heat and slow movement seemed to melt the paint off an inch or so ahead of where I was working. Also, on areas where there was still sound deadener, I welded from the bottom first and intentionally made very hot, long passes. The intense heat allowed me to go topside quickly and using the scraper peel back the deadener. It was extremely easy one light pass got down to bare metal when it was hot. It practically boiled itself off.

Tomorrow I hope to get both seat mount rails into the passenger side and make some headway, if not finish the passenger side rear torque box. If I am really moving, I'll be able to get the jacking rail and matrix completely mocked up.

Overall, I am extremely happy with how it turned out so far. I don't know how I want to close off that opening at the top of the rear tube, this is the first time I have used the combination of 2x3 and 2x2 (I have previously only ever used one or the other). I have a simple idea, which would look ehhhhh, and a difficult idea, which would look much more aesthetic. The attention to the measurements and keeping everything level in both dimensions really payed dividends...when I layed the center piece in and lined up the bottom of it to both the front and rear tube it was perfectly level in both directions, I didn't need to install it on an angle at all. In the end, that looks better, and provides better strength. Is all this worth the PITA? That's your call, I'm already too far down the road to even entertain that debate now.

New toys. The day my tools arrived from Summit someone put nearly the same exact stuff up on Corral used, and also the clutch. He cut me such a great deal overall that it makes sense for me to return the Summit stuff. I only eat the shipping within the first 60 days no restocking fee.

My cordless sawzall also arrived but I did not take a picture of it. According to the slip on my door, my cordless impact gun is also here. I stopped by Harbor Freight as I found the receipt for the second drill and attempted to return it, this time I just wanted store credit. Apparently, the 30 day warranty only extends to the first item, not to any replacement items. Humph. I'll stick to buying consumables from them and nothing else.

I got the driveshaft done at work this week in some spare time.

And the brake caliper brackets.

Upon arriving at the garage, I verified that the chassis, and then the front tube is level both vertically and horizontally for the 128,228,573rd time.

Slid under and welded the front of the front tube. Welded the underside of the tube to what remains of the channel.

Then cut and welded in the firewall footer plate. 4x6. Pretty thick sheetmetal along the bottom and sides but thin up top, watch it.

16.5" center section.

Cut the floorpan, angled both ends.

Tacked it in checking level in both directions.

Finish welded it, as well as the floorpan to it.

Of note, the weld where the center section meets the front section. A triple pass to ensure I got good penetration. This weld lands directly in the middle of where the seat would mount and in an effort to get the seat as low as possible and have as much clearance as possible this weld will be ground down. Therefore the overkill.

Front section welded to floorpan.

At this point, the sacrificial bracket can be removed and the rest of the front section bottom welded to the tunnel.

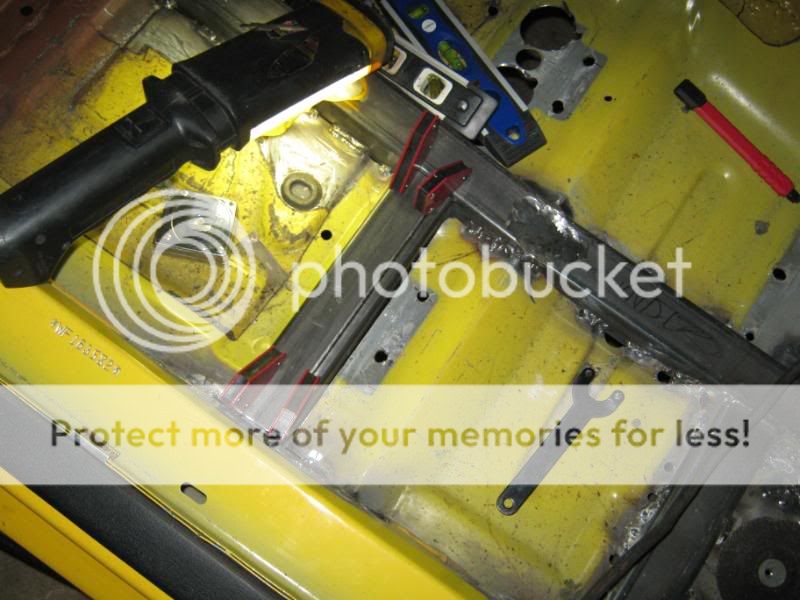

The replacement 4x4 seat mount/rocker footer plates installed. Much grinding/hammer/vicegrip was needed on my mangled pinch welds.

I wanted to start cutting the seat mount rails but I was running low on time and on argon. I wanted to finish off the tank so I could take it with me and pick up more on my way to the garage tomorrow since it's 5 minutes from my house and an hour from the garage. So I just finished 90% of the rest of the welding of the SFC to the floorpan, being careful not to weld the areas where the seat rails still needed to go and causing myself more work.

There were some serious gaps in areas and it's hard to figure out how to go from wanting good penetration (hot, high settings) of the .125" thick tube and not blowing through the thin 18 gauge floorpans (typically slow, low settings). I found it best to start welding only on the tube and use multi-pass welds to create a shelf to extend almost touching the floorpans on the highest settings (think creating a bridge one plank at a time). Then turn it way down and use a series of tacks to bridge the last small plank to the sheetmetal so it did not burn through. I welded both top and bottom from the same points. Once the bridge was created on one side, it was pretty easy on the other side to just leave it turned up since the welds are very thick and would not blow through.

I fixed the welder earlier in the day. I have been questioning myself lately if I need more classes I could not figure out where all this spatter and rough welds that stand way up are coming from. It turns out I had the feeder set way wrong, causing intermittent flow of wire, therefore spattering, therefore BBs and jams, and therefore poor heat/poor penetration/poor laydown/standup. Another interesting thing I noted was that in my rush, and emboldened by my now insanely hotter welds I blew right through the paint that remained on some of the rear floorpans and it made little difference. I simply used a little bit hotter setting than I normally would with very slow handspeed...the intense heat and slow movement seemed to melt the paint off an inch or so ahead of where I was working. Also, on areas where there was still sound deadener, I welded from the bottom first and intentionally made very hot, long passes. The intense heat allowed me to go topside quickly and using the scraper peel back the deadener. It was extremely easy one light pass got down to bare metal when it was hot. It practically boiled itself off.

Tomorrow I hope to get both seat mount rails into the passenger side and make some headway, if not finish the passenger side rear torque box. If I am really moving, I'll be able to get the jacking rail and matrix completely mocked up.

Overall, I am extremely happy with how it turned out so far. I don't know how I want to close off that opening at the top of the rear tube, this is the first time I have used the combination of 2x3 and 2x2 (I have previously only ever used one or the other). I have a simple idea, which would look ehhhhh, and a difficult idea, which would look much more aesthetic. The attention to the measurements and keeping everything level in both dimensions really payed dividends...when I layed the center piece in and lined up the bottom of it to both the front and rear tube it was perfectly level in both directions, I didn't need to install it on an angle at all. In the end, that looks better, and provides better strength. Is all this worth the PITA? That's your call, I'm already too far down the road to even entertain that debate now.

nice bro. glad you got your welder problem figured out

nice work PGT, that iced up shot is pretty cool.

Got a pack of the same welding holder thingies last week as you show a few posts up, they're handy.

Powder coating finish is awsome isn't it! I got my front Cals, and brackets coated about 8 years back and they still look new.

Suggestion: when welding - like on your sub frames, you should take a wire wheel on your grinder, and take off the paint.

you'll get a much nicer looking weld and it will be stronger because you're not burning paint into it.

I'm also curious, and maybe I missed it in the reading - why do you do all the hole-saw cuts - why not just cut it out with a cut-off wheel in a grinder?

and like I said, nice progress man

Got a pack of the same welding holder thingies last week as you show a few posts up, they're handy.

Powder coating finish is awsome isn't it! I got my front Cals, and brackets coated about 8 years back and they still look new.

Suggestion: when welding - like on your sub frames, you should take a wire wheel on your grinder, and take off the paint.

you'll get a much nicer looking weld and it will be stronger because you're not burning paint into it.

I'm also curious, and maybe I missed it in the reading - why do you do all the hole-saw cuts - why not just cut it out with a cut-off wheel in a grinder?

and like I said, nice progress man

Dalamar said:Suggestion: when welding - like on your sub frames, you should take a wire wheel on your grinder, and take off the paint.

you'll get a much nicer looking weld and it will be stronger because you're not burning paint into it.

I'm also curious, and maybe I missed it in the reading - why do you do all the hole-saw cuts - why not just cut it out with a cut-off wheel in a grinder?

I've been doing that in places and skipping it others. It really seems to make no difference. Some joints I've gone so far as to wire wheel, then chemical strip, then wire wheel, then clean off with a rag and parts cleaner and the weld still seems to be contaminated with the tiniest bit of foreign material in the joint. These last few welds do not appear as great as the first few because I haven't taken the wire wheel to them pre-picture.

I use the hole-saw method to visually help me sort everything out. It also leaves a lot more material in the floorboards in case you miss a bit, meaning smaller gaps to fix. Different strokes for different folks, I guess. After I have the piece cut to fit in said hole, I go back with the cutoff wheel and cut them straight, then the grinder and take away little bits until I get the tightest fit I can (given my timeframe and available patience...).

Well, you know I got a lot done when I'm not even uploading my photos until 10:30PM. Wow - I normally have 20-30 pictures on a normal day. I have 73 today. Corral is going to take forever to upload when I do on there.

Toys! Turns out I'm an idiot, again. That's an impact driver, not an impact gun stupid, read the auction better next time. Oh well, the driver goes back up on eBay, and I keep the two new batteries and charger, worth the price anyhow. Saw works pretty good. The LEDs are neat. Picked up some .030" wire for the welder and tips. First time I've used it with MIG. The .023" allows me to go down to 22AUG sheet but the .030" cuts wire speeds down from the high 80s into the 20s. So I should consume it a lot slower. Also the weld pool is considerably wider and stays hotter.

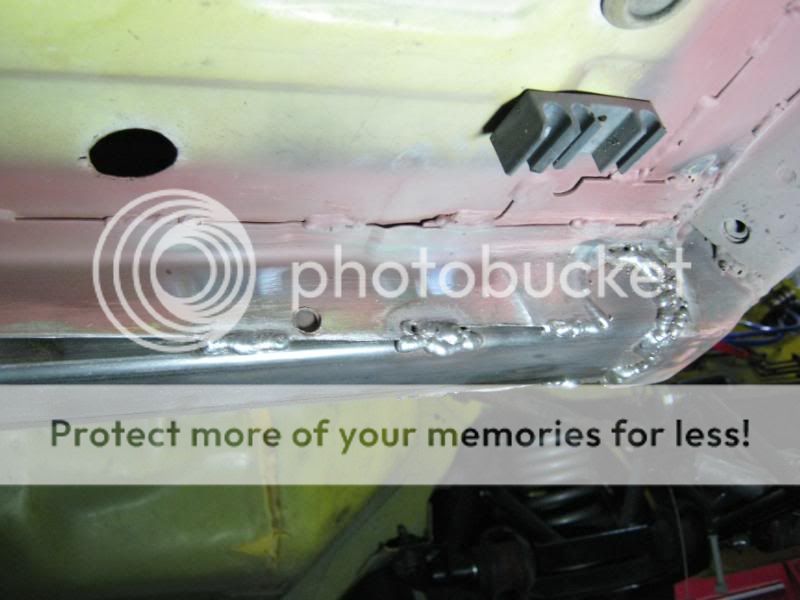

Finished that welding I was supposed to get to on the underside of the center section.

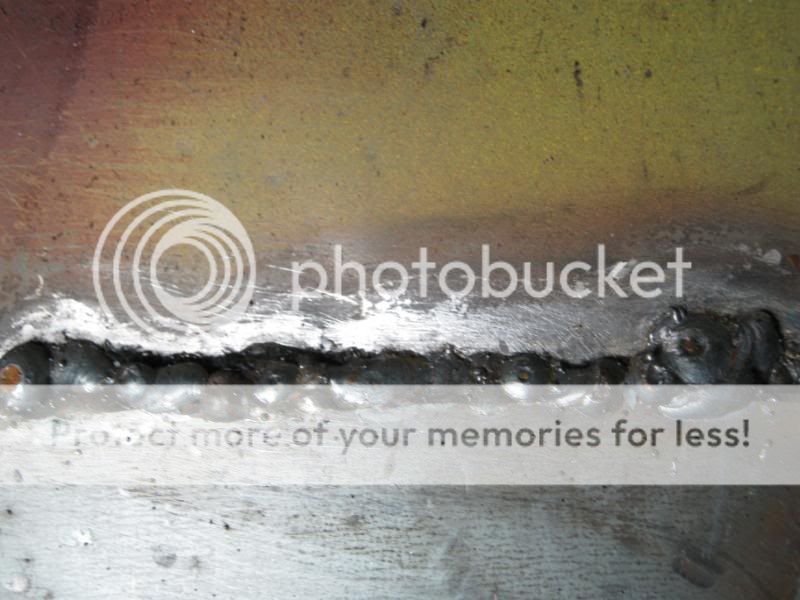

Before I really get into it, a comment about the welder and what I meant. Because the wire was feeding intermittently, it gave a pulse type effect. Think of holding the trigger for two seconds and then blipping your finger off, then two, off, two, off. Some guys do this on purpose to create TIG-appearing welds with MIG. First picture is effect.

When you're intending to do it in the car world, if you're selling welded products it can help you sell your product as the general public assumes TIG is superior to MIG and assumes all welds should appear stack-of-dimes like that one does. Typically TIG gives this effect. In reality, MIG is just as strong of a process (both, if done correctly) and the final appearance of a weld is really irrelevant so long as they have no contamination and good penetration. But, consumers are stupid and think TIG = better and stack of dimes will definitely help sell your product as the general internet audience is going to look and say OMFG look at those welds want want want. Unfortunately, when you can't control the pulsing, you get these type results...high build, poor penetration, no heat buildup. So essentially fixing my junk makes my welds look worse in most cases, but actually be a lot more sound.

Outlining and cutting the front outside seat brace cut. I think this was 9 1/2" or something like that.

Getting this bastard to go where I wanted it to, level in both directions. Also note, check level (in relation to car left-right) both at the center of the brace, and at the overlap of the brace to the SFC to ensure the brace is flush with the SFC.

After tack, weld. Top, then bottom. Or vice versa. I'd suggest weld the hardest welds first, the ones deep in the corners, and work your way out.

In the above picture, note the high bump in the floorpan. I determined (same reason I ground down those welds...) that since this bump was higher than the highest point of the seat braces or SFC it could become an intrusion into seat mounting or movement and had to be pursuaded. Recess cut, hammer, weld. Real light settings, something like 2/15 I was using.

You can still get nice results welding correctly. This was a 15 push C motion. What I'm using on most of my welds, but this one turned out especially good. It just comes down to practice practice practice. Fabricate well, get good tight gaps, then be consistent with your hand motion and once you have it going don't stop.

Onto the rear outside seat brace, this one intersects the centersection which is on a slight angle so it's a bit trickier. I think something like 9 5/8 on the short side and 9 7/8 on the long side.

Same deal. Draw. Cut. Fit. Grind. Fit. Grind. Fit. Grind. Fit. Grind. Magnet. Level. Level. Level. Grind. Level. Hammer. Level. Hammer. Level. Tack. Clamp. Hammer. Level. Level. Level. Tack. Weld.

Now, if we put the big level across both outside seat braces...Baddah bing!

Time for the inside ones. 11.5" piece cut in half. Measure 6.25" flip it over and measure 6.25" from the other side. Cut and you end up with just about a 45 degree angle. Weld endplates on, cut to size, grind the edges down. On one of them, account for the 1/4" taper that the center section has.

Same process for the rear one (the tapered one).

Front one, same thing. Can be a bit tricky you'll have to cut the floorpan and spend extra time grinding this one due to the way the floorpan comes up the center tunnel.

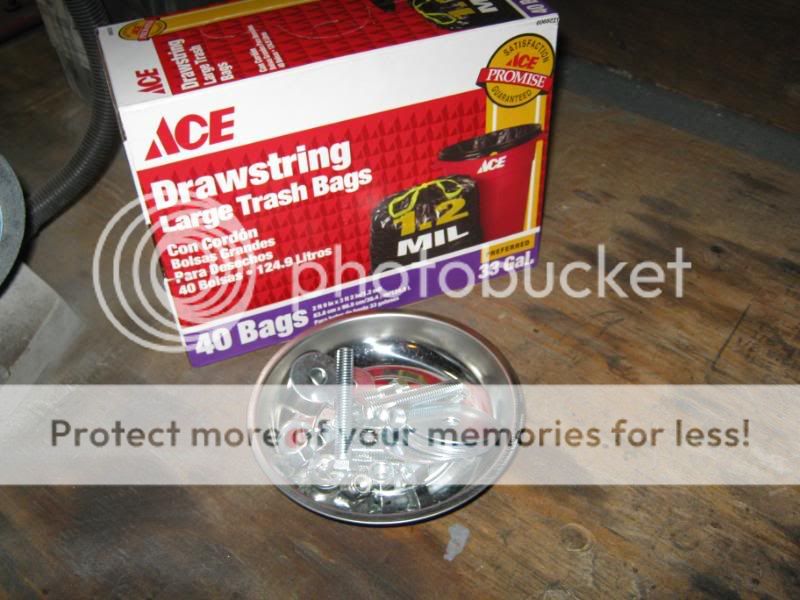

Very low on gas (did I get a full tank, that went fast?) so I did not finish weld the last three. At this point it was a good time to run out and get my haircut (first in months) since the hardware store is right next to it as is Dunkin Donuts (I should get a sponsorship, I've spent $3-$6 every day, sometimes two and three times a day, since I've had a driver's license and a car). Came back with some goodies. Always need more trash bags, hardware for playing around with side skirt mounting, and my personal fetish another magnetic tray. I think that brings my total including the ones I have at work to six. So useful.

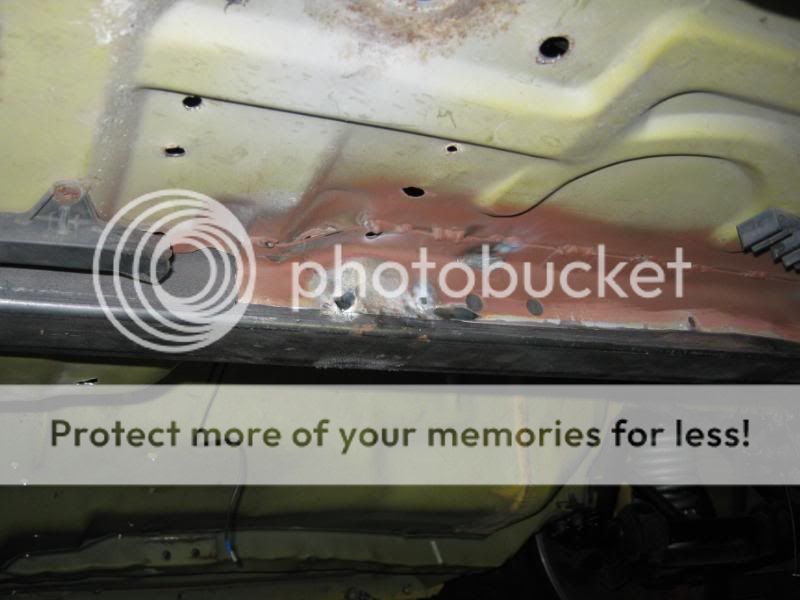

So back to that passenger side lower torque box. This is where my night got really, really bad. Started on the piece that was still attached to the pinch weld with the new recip saw, prybar, and vicegrip.

As Gene said, there is no correct way to remove all this metal. Just start cutting. Recip saw + vicegrip cut out a random triangle. I was trying to be organized about this at first but you really just need to cut it into small, bite size random shapes. As you go more and more you get more room for your tools to fit in.

The decent sized center fin lost to the cutoff disk, vicegrip, plier, and recip saw. I was trying to be relatively quiet in respect to Princeton noise laws (after dark STFU). So I tried to use the cutoff disk as little as possible although it would have made some steps faster.

Random little strips left where the LCA actually bolts to. Here I finally had enough material removed I could get in there with the cordless drill and my new step bit (the real skinny one I love).

This last MOFO, the thickest piece that forms a U shape that the LCA actually goes into, that is spot welded to the floorpan and the frame rail, single handedly took longer than all the other pieces combined. Not only does it have an insane amount of spot welds to get out that are in impossible to reach spots and angles, it holds on for dear life after you get them out and it's stupid thick, it takes SO long to drill through them pushing upward with everything you got. I think my guns grew a full size doing this project. Anyway, it's all cleared out now.

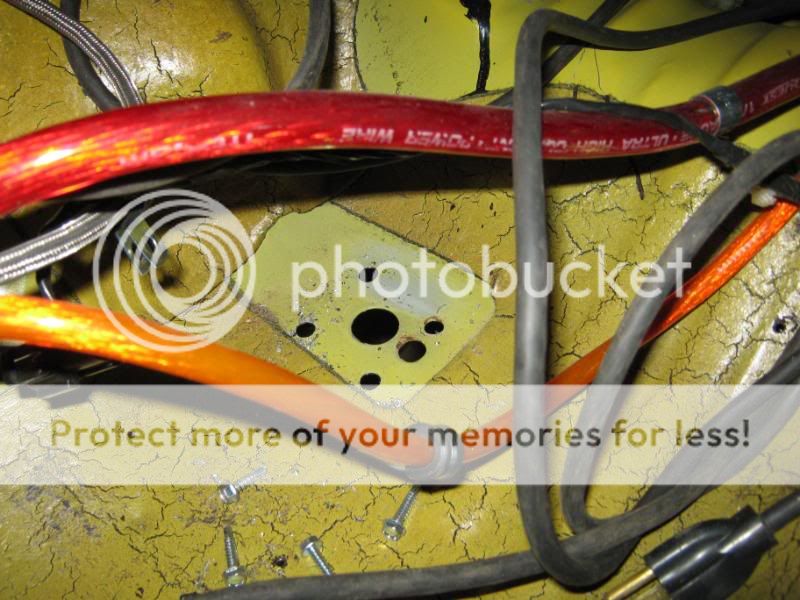

I need to finish grinding down some of what is left of those spot welds and then chemical strip the area to deal with that rust. I'd like to chem strip it all then use the wire wheel to see how deep it goes. For crying out loud, it's on the inside of the main frame rails (not as bad) so it's nothing I'm going to cure now but it will give me an idea if I'm ever here again whether I'm going to need new floorpans or just to completely strip and sandblast this chassis. The passenger side inside lower rear seat belt bracket now falls under the "unnecessary interior bracket" rule. Luckily you can see the spot welds from the interior of the car so I started the drilling in there and finished it underneath.

Unfortunately my favorite unibit was killed in the line of duty. He will be missed, he was the most useful of the bunch and an insane timesaver.

Tossed up the Wild Rides lower S-box for a quick look. Tell me that does not look completely fucking bad ass.

This is a picture of the ten million metal shards I was laying in doing this job, which turned this job from hellaciously difficult to absolute, pure hell. Everything from the tiniest little BB you get when grinding to razor sharp pieces as big as pencil shavings. Down your back, on your neck, in your hair. Not to mention you are laying in it, looking up, having new pieces RED HOT rain down on your arms, face, neck, hair. For once I was in full safety gear - wet hat, full face shield, welding gloves, long sleeves...and I still have some pretty nasty burns on hands, arms, and face, one a half inch or so from my eye. Totally worth it though, those S-boxes are INSANE. Just more motivation to get a lift. Or a house, with my own garage, with a lift.

Yanked the passenger side interior C pillar trim, speaker panel, sound deadening, and rear seat belt. Took a few reference pics for this week when I'm deciding on stuff that needs deciding on.

That is all. Stupid UPS is trying to deliver something that requires signature so I have to come home tomorrow after work no choice. I need to start getting over there more on days where there is little work and I leave early and getting projects done at work and at home (such as trans) on days where I leave at normal time (no sense in going over there if I get out at 5-5:30 since I'd be there at 6-6:30 and it's already dark.

Corral has a 20 pic/post limit. This is going to take a minute...

95PGTTech said:Before I really get into it, a comment about the welder and what I meant. Because the wire was feeding intermittently, it gave a pulse type effect. Think of holding the trigger for two seconds and then blipping your finger off, then two, off, two, off. Some guys do this on purpose to create TIG-appearing welds with MIG. First picture is effect.

That is a nice looking weld, and I do that technique you're talking about. it actually has beter penetration than just running a straght pass.

in this picture I can see from the edges and the heat marks that you have good penetration on both sides.

the key it to not let it cool too much, it should stay glowing hot as you go.

A day in the life of a fabricator95PGTTech said:Same deal. Draw. Cut. Fit. Grind. Fit. Grind. Fit. Grind. Fit. Grind. Magnet. Level. Level. Level. Grind. Level. Hammer. Level. Hammer.

I've never broken a unibit - props on that!

US Soldier(stang 98)

Well-Known Member

yet a nuther epic build. good work man

it took 20 minutes to load this page in my hotel room... (yes, thats a good sign)

the seat rails look great. I cant wait to see you start putting it back together

the seat rails look great. I cant wait to see you start putting it back together

I was a lazy pile of **** this week. Monday I showed up late and have to leave early due to track anyway so I only put 5 hours in total and I took Tuesday off. I left work early the last two days due to lack of work and just sat around the house again so I need to break this streak before it becomes another long cycle of nothing done. I don't work until 430 tomorrow so Adam and I are going to try and make it over to the garage to make some progress.

I picked up some spray-on chemical stripper being as I had to do the torque box area straight up. Just doing the small amount I did under the car already the paint on stuff is very messy. This is "aircraft grade" so it should be stronger, right? One is paint remover the other is base coat remover. It's still a giant, messy ordeal and really gets very little off. If anything, it just weakens it up for the wire wheel to come blasting through to the bare metal.

I removed the last of the rear seat belt passenger side mounting tabs.

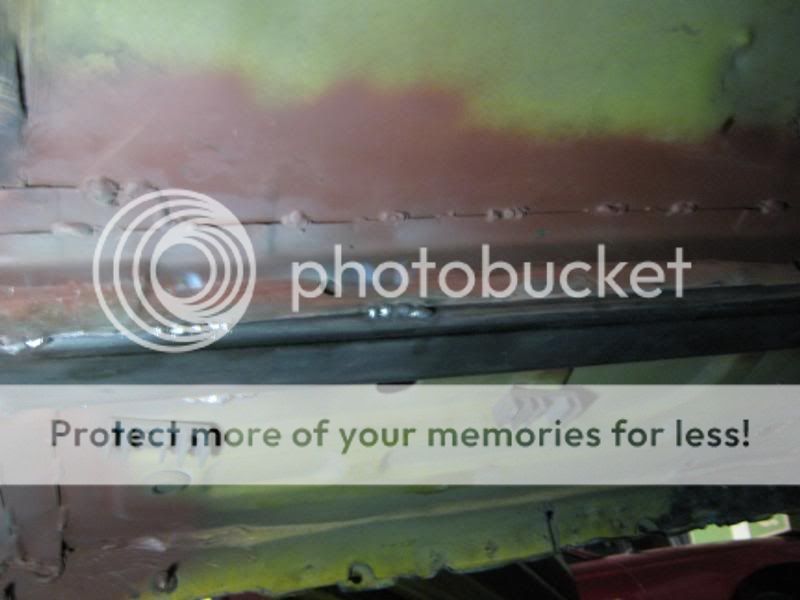

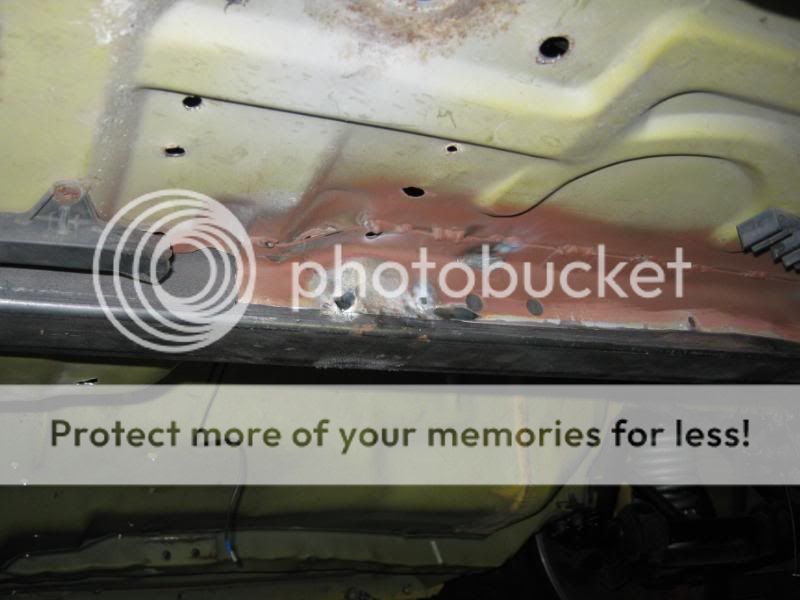

Fully (as best as I could) stripped torque box area. The brown is that primer I was using before. Honestly, the rust is not that bad. It did get under the factory primer and peeled and chipped it off in many places but the rust is not beneath very far. The wire wheel got 99% of it and I'm hoping a good coat of primer will slow it down to get me through another year or two until funds permit a larger-scale restoration...there's a scary thought, eh?

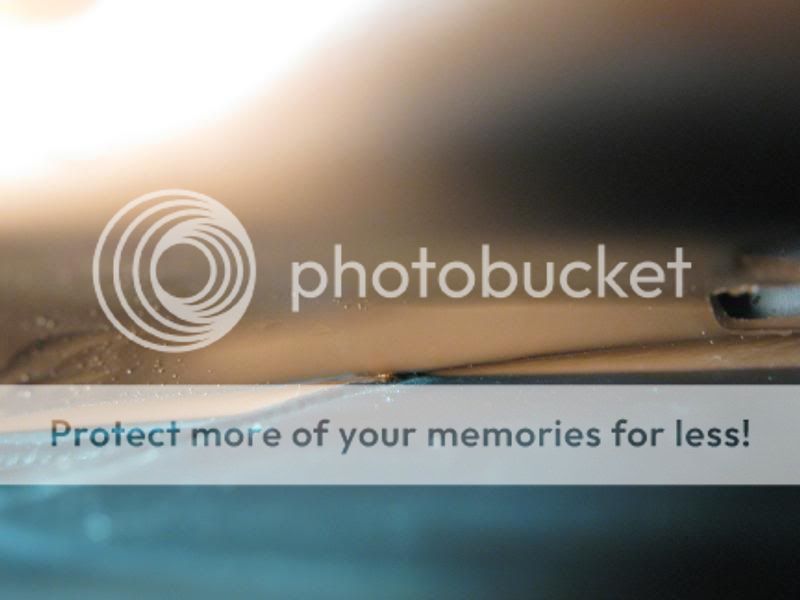

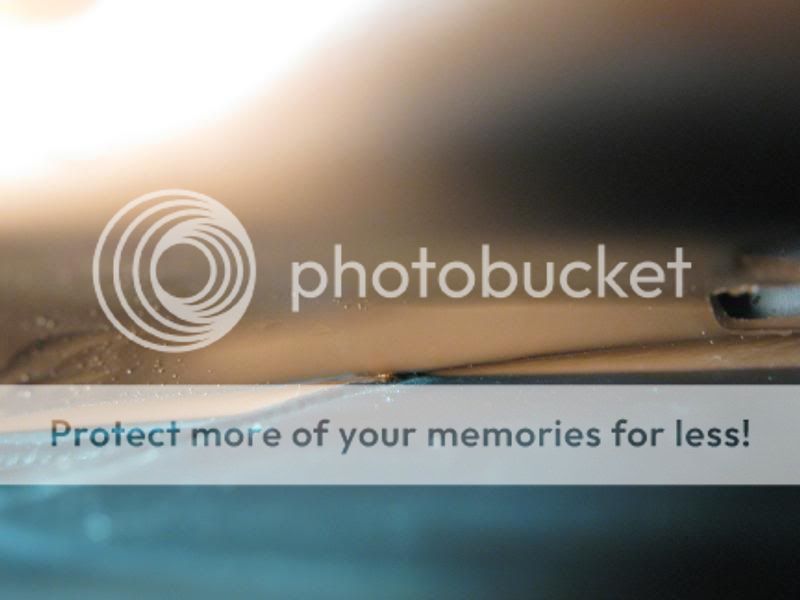

I finished seam welding the area that the replacement torque box would go into and not allow me access to anymore. This gives you an idea of what even my small welder is doing for heat. This is the wheel well area of the rear wheel. This is the inside of the wheel well - I was welding on the other side on two 1/16" thick pieces of metal and all this heat still came through that and peeled up the undercoating in the wheel well.

A piece of undercoating still on fire decided to drop down onto me and give me a new access hole through my sweatshirt. Thank goodness for crappy work clothes and 3-4 layers - it was a good 30 seconds of burning before I noticed due to smell.

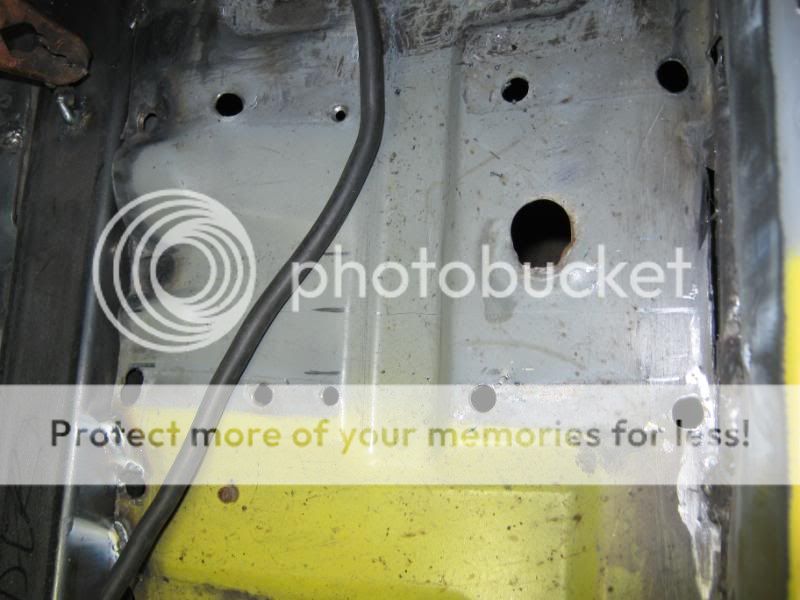

The rear lower control arm bolt access hole needs to be opened up to allow you access to the new highest mount. I chose the hole saw and it made pretty quick work of the job.

Primer!

Ground down the edges of the torque box clearancing it (my seam welds got in the way) then ground the paint off the edges I think I need to weld eventually.

Bottle jack ftmfw, these are heavy and I'm a small guy!

Trying to show the clearance between the new torque box and the rocker panel on the outside of the car, then the new torque box and the rear subframe rail. There is a notch you can see in the rear subframe rail. According to Gene's direction, this needs to be extra clearanced to fit the torque box even tighter up to the floor pan and to the rear subframe rail. Not understanding, I called him and I think I understand what he means now.

That is all. Yeah, I know, suck ass update.

In other news, new toys! (Not pictured Hobart 10lb spool conversion hub) two 10lb reels of .030", a new gun liner to hopefully finish off the last of the ****ty wire feed issues, nozzle gel, nozzle brush. I didn't spend that much this week, got her camera fixed, and made DOUBLE my normal paycheck = happy wife. We'll push our luck next week with new parts.

I picked up some spray-on chemical stripper being as I had to do the torque box area straight up. Just doing the small amount I did under the car already the paint on stuff is very messy. This is "aircraft grade" so it should be stronger, right? One is paint remover the other is base coat remover. It's still a giant, messy ordeal and really gets very little off. If anything, it just weakens it up for the wire wheel to come blasting through to the bare metal.

I removed the last of the rear seat belt passenger side mounting tabs.

Fully (as best as I could) stripped torque box area. The brown is that primer I was using before. Honestly, the rust is not that bad. It did get under the factory primer and peeled and chipped it off in many places but the rust is not beneath very far. The wire wheel got 99% of it and I'm hoping a good coat of primer will slow it down to get me through another year or two until funds permit a larger-scale restoration...there's a scary thought, eh?

I finished seam welding the area that the replacement torque box would go into and not allow me access to anymore. This gives you an idea of what even my small welder is doing for heat. This is the wheel well area of the rear wheel. This is the inside of the wheel well - I was welding on the other side on two 1/16" thick pieces of metal and all this heat still came through that and peeled up the undercoating in the wheel well.

A piece of undercoating still on fire decided to drop down onto me and give me a new access hole through my sweatshirt. Thank goodness for crappy work clothes and 3-4 layers - it was a good 30 seconds of burning before I noticed due to smell.

The rear lower control arm bolt access hole needs to be opened up to allow you access to the new highest mount. I chose the hole saw and it made pretty quick work of the job.

Primer!

Ground down the edges of the torque box clearancing it (my seam welds got in the way) then ground the paint off the edges I think I need to weld eventually.

Bottle jack ftmfw, these are heavy and I'm a small guy!

Trying to show the clearance between the new torque box and the rocker panel on the outside of the car, then the new torque box and the rear subframe rail. There is a notch you can see in the rear subframe rail. According to Gene's direction, this needs to be extra clearanced to fit the torque box even tighter up to the floor pan and to the rear subframe rail. Not understanding, I called him and I think I understand what he means now.

That is all. Yeah, I know, suck ass update.

In other news, new toys! (Not pictured Hobart 10lb spool conversion hub) two 10lb reels of .030", a new gun liner to hopefully finish off the last of the ****ty wire feed issues, nozzle gel, nozzle brush. I didn't spend that much this week, got her camera fixed, and made DOUBLE my normal paycheck = happy wife. We'll push our luck next week with new parts.

Put 7 hours in cars today...pretty cool since it wasn't a scheduled day. Didn't touch my car at all but made a lot of headway on Adam's car and worked on the welder. Put the 10lb spool kit in and the new gun liner. Out of gas so couldn't test it out but just running some wire through the gun felt much better.

duff daddy

Legend

hobart makes a nice product, ive always had good luck with my lincoln and the Miller we have here at work (220) but either way, nice progress,