MustangChris said:

dang man. that is alot of digging. what are the major gains of the s box?

The lower, which I am installing now, has three mounting holes as opposed to the stock one of one. The stock location, one above, and one below. Without going too much into the rear suspension geometry, you can really help a car squat if the class you run allows relocation of the front LCA point - some don't, that's why the middle hole is in the stock location. Some people have simply torn the lower torque box so bad reinforcements will not suffice. Such was the case for me.

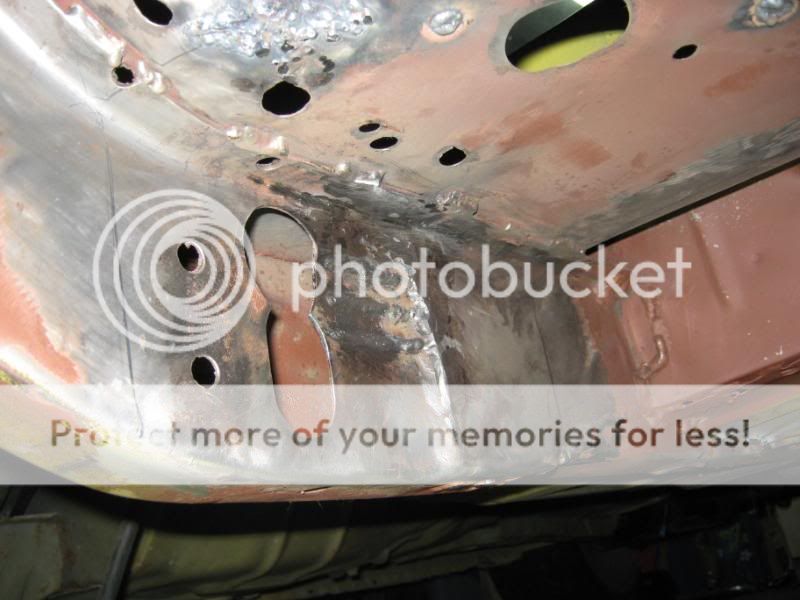

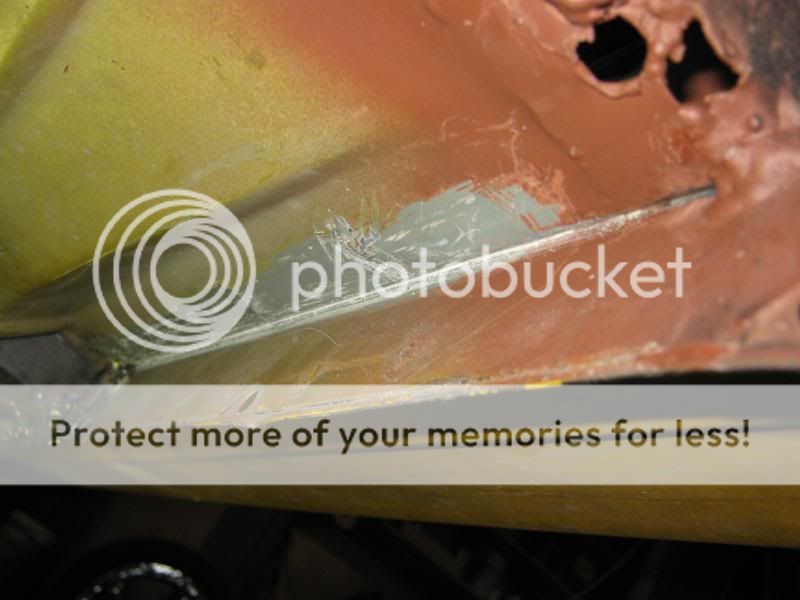

I promised a pic last time of the horizontal cuts.

Welded, ground down, put the S-box up and marked the perimeter.

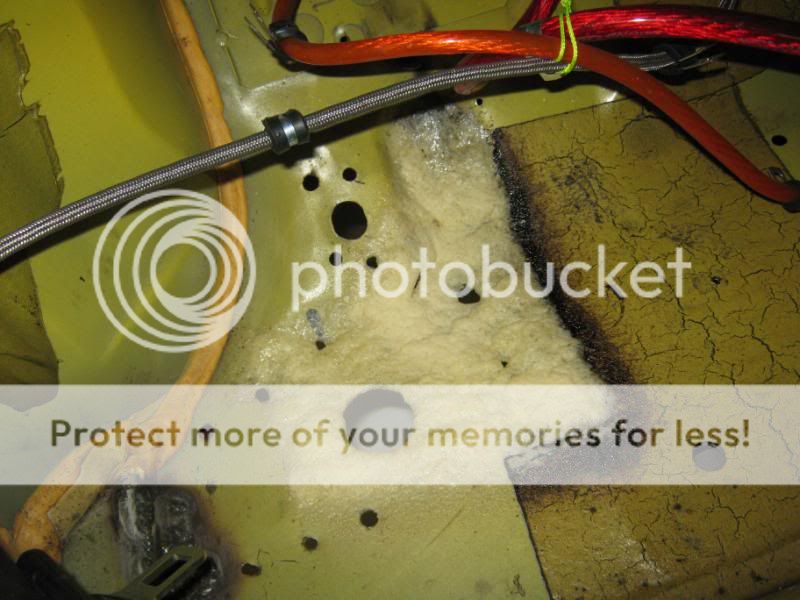

My intention was to tape off the area which would be covered by the S-box and paint it. I then realized I had a lot more welding to do first, between plugging holes that I would never have access to again to welding the top floor plate in. This welding would burn away the new paint and just let rust right back in.

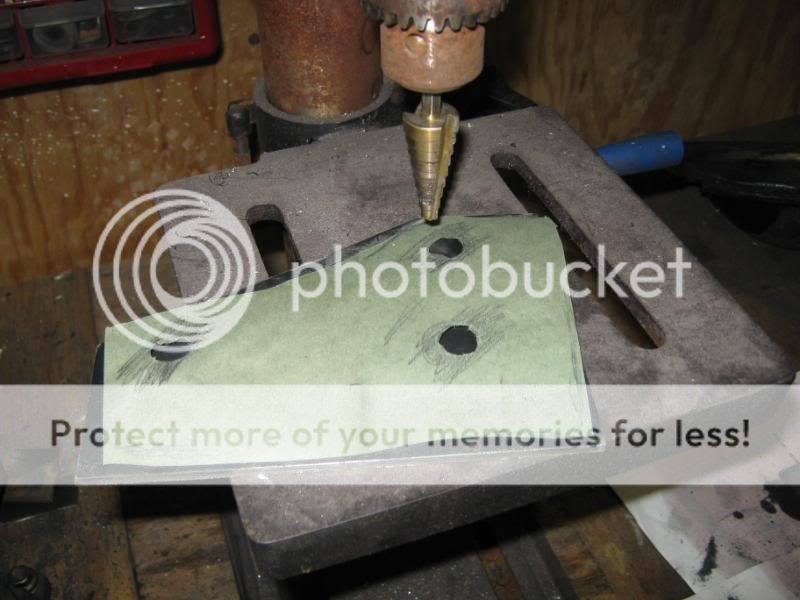

Made my template top floor plate out of paper, transferred to 1/8" plate, drilled the holes on the drill press, tack welded it in, then finish welded it. Man, was it a task welding a 1/8" plate to 22AUG steel (.003" versus .120"). I have been struggling the past two days with my Hobart Hood (helmet) and the auto-dim. The screen is just really foggy. So I ended up switching to an older straight -10 filter helmet and laid down some of the best welds of my life actually being able to see for once.

Went to Ace and picked up some more hardware now that I decided which of the hardware I picked the first time I was going to use. At under a half dollar per, I'm having a field day. And bought another metal tray. My wife rolled her eyes.

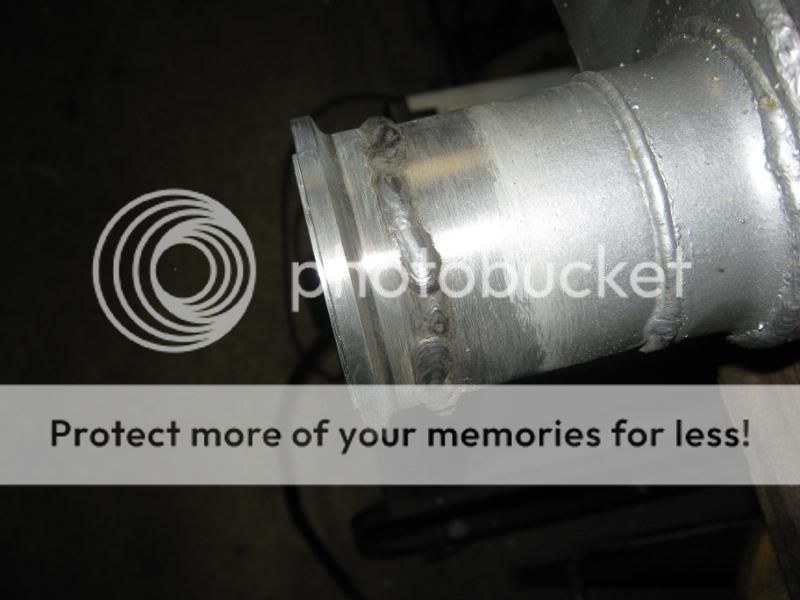

I was saying about the welds.

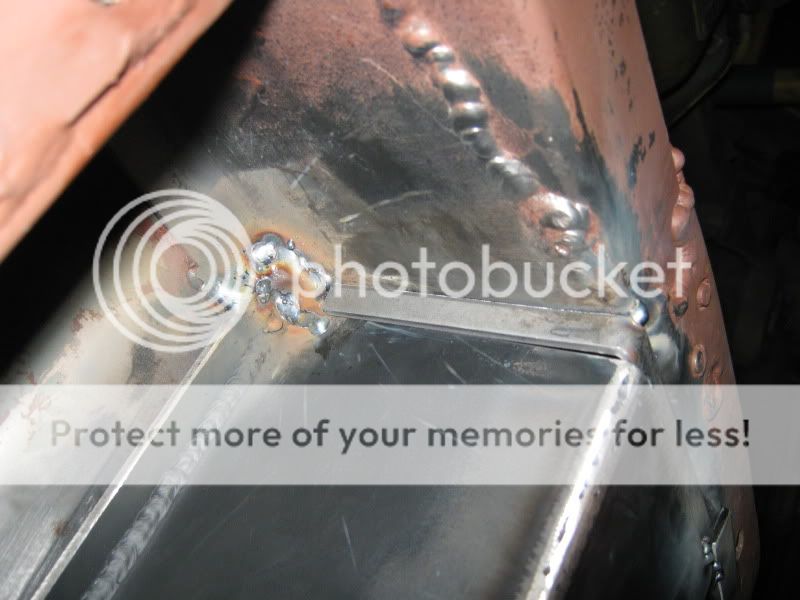

I decided to test on something "easy" to see if I really was making any progression in my skills (or lack thereof). There is still a ton of welding to be done on the seat rails and floor pans everything is just real solid tacked in right now so I did one of the top SFC to seat-rail joints. And I just dropped a bomb on it, I wish all my welds were anywhere near this flat, this consistent. Great penetration, great heat, it even looks nice. Remember when I did the others I had to grind them flat for seat clearance...no grinding this one is so flat. Hopefully I can have more results like this in the future and less rhino snot.

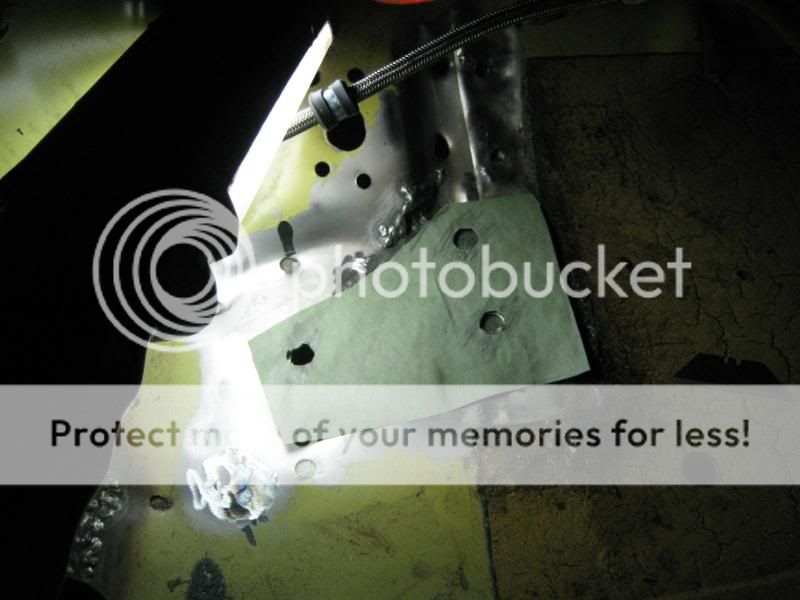

Mounted the S-box for the first time without a jack. Glad I drilled the holes in the plate, floorpan, and S-box two sizes over the bolt size so I had room to muscle it around.

Installed the bolts the opposite way of the directions hoping to be able to tack weld the heads of the bolts to the floor plate...no dice, the hardware comes in too deep and would hit the LCA on the stock or highest setting.

Flipped them, VERY SLOWLY and rotating often tack welded the nuts on just two of the six sides. Worked out good.

I'm happy with the fitment so I stenciled the outline again. This time with all the holes plugged, ground down, and the top plate welded in.

Masking tape, primer, paint. I was going to do my chrome yellow i have in aerosol but this rustoleum black should cover up bad ass and who knows if we're ever going to paint the car. I've never seen a black undercarraige that looked bad.

A couple excessive tacks to hold it in place. Bolts do 90% of the work but want to pull one corner up. Not so great welds on my back in tight spots holding the mask with one hand. But they'll hold.

Damn near no gas left, late. Cleaned the seam seal out of the weld top and bottom that goes where the rear most jack rail goes. I was going to stripper, wire wheel them again but decided to take a short cut. If you move really slow, it burns through the paint pretty damn good. Just watch out for those fumes.

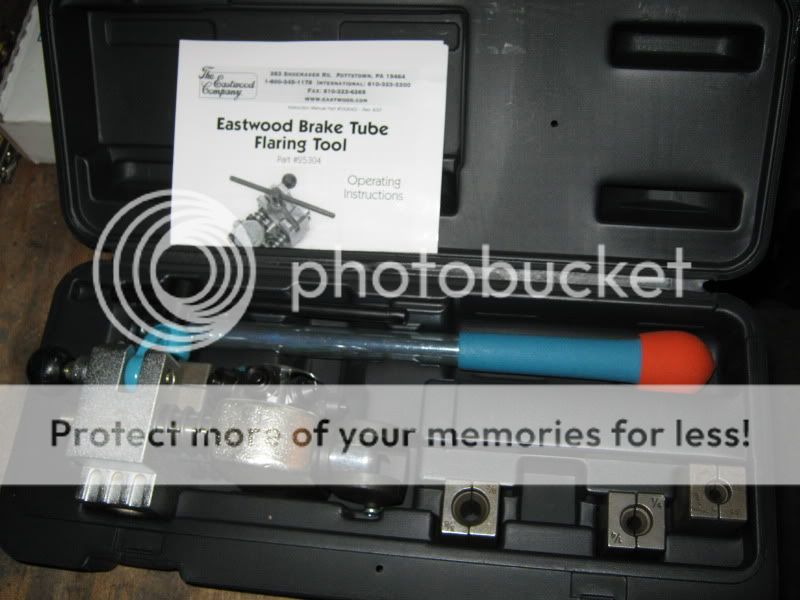

organized some junk in my time left, took another trash run, found some old fuel line stuff I won't have to order now.

My goal was to be test fitting the side skirt with the new mounting system by the end of Monday, and we're still finish welding the S-box and installing the rear jack rail away from even a first attempt at fitment. Oh well, an inch at a time, right?