Another day, another parts delivery

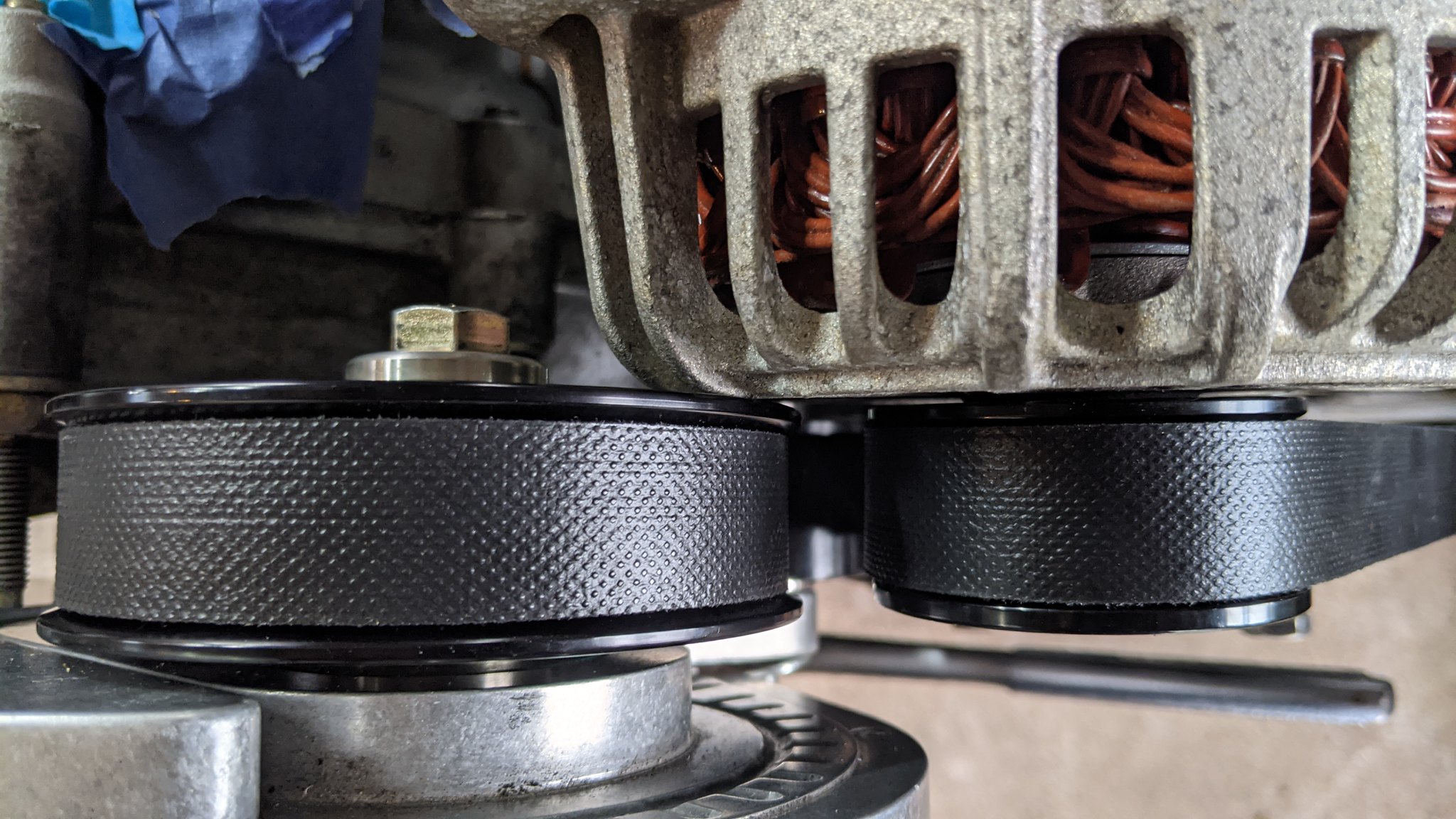

One of the two belts I ordered arrived along with a fuel hose, but more on the fuel hose later. I routed the serpentine belt and to my surprise.. it fit! It is a 114.2 inch belt Continental belt, part #4061142. It was suppose to be just your regular belt, but they sent me their "Elite Series" belt, which is actually a gatorback style belt and I'm not complaining. It fit perfectly, not too tight, not too loose.

However I did notice that with the alternator in loosely in place that the case of the alternator is resting on the pully of the P1SC. Now I

think this will self correct itself once the intake manifold is on and the top alternator bracket is screwed in place, i dont think this will be an issue.

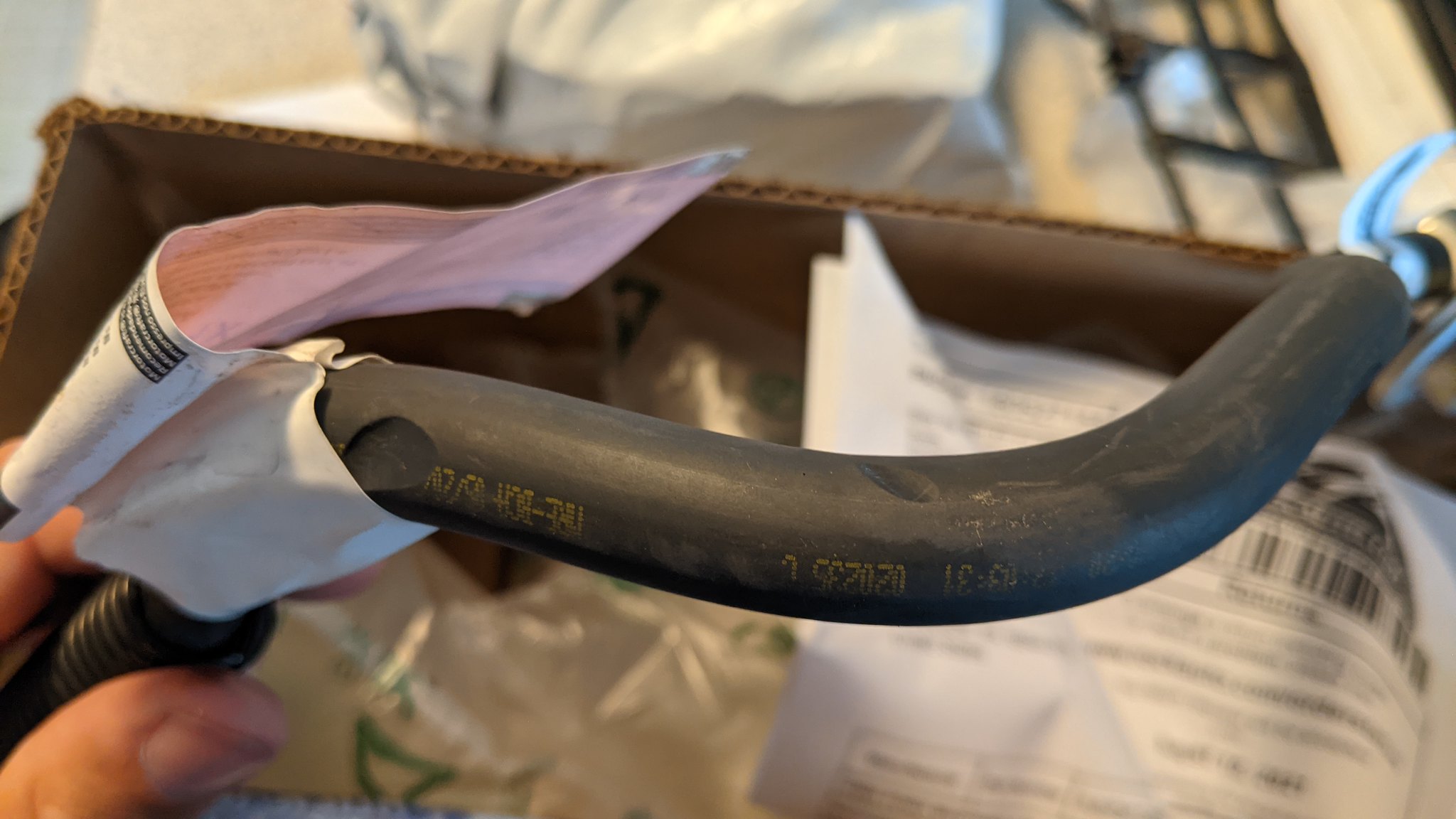

Now about that fuel hose I mentioned earlier. I wanted to replace the the fuel line connection that runs from the hard fuel lines from the passenger fender area to the fuel rail. I wanted to replace this as my current hose had a somewhat deep gouge in the rubber and it made me feel uneasy. Found out Ford still makes them and ordered a new one from rockauto. It arrived and has more gouges in the rubber than my 21 year old hose does! It has probably 6-8 different gouges in the rubber. What would you guys do? Ask for replacement one, or just send it?