Maybe I have already asked this, but what intake manifold do you plan to use? I ask because ive dabbled a little bit in manifold modifications and I would think 2 edelbrock manifolds hacked together would suit your engine build well and package under the hood.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Forbidden Fruit, 6.8L PI 2v v10 build

- Thread starter Snorky

- Start date

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Well.. my options are cut up the stock intake and make that work or do the dual Eddie's and a custom elbow. The way it looks to me is the stock intake will probably be significantly cheaper. Since you have 800 between 2 eddies.. then welding them all together/widening them.. and then making an adapter/elbow for a 96-98 cobra throttle body. Not sure what to do.. my gut tells me a v10 modified would probably be a lot foe the fab work.. while the 2 Eddie's starting price is 800 without fab work.. a hard enough pill to swallow. Since it all has a height restriction. The stock intake as is won't fit under a 95R hood. Even with 1/2" k spacersMaybe I have already asked this, but what intake manifold do you plan to use? I ask because ive dabbled a little bit in manifold modifications and I would think 2 edelbrock manifolds hacked together would suit your engine build well and package under the hood.

Last edited:

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

You offering to farm out your services?Maybe I have already asked this, but what intake manifold do you plan to use? I ask because ive dabbled a little bit in manifold modifications and I would think 2 edelbrock manifolds hacked together would suit your engine build well and package under the hood.

Musturd

Post Whore

- Joined

- Feb 12, 2011

- Messages

- 10,500

- Reaction score

- 2,267

That sounds cool

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Right?! My issue is the starting cost for a custom eddie is some 800 for 2 eddies.. then the fab work comes into play. And the idiot I am.. I bought a DC multimatic 215.. didn't anticipate custom aluminum intake manifolds.. and well.. here I am. So the cost of fab work is the questionable ticket.. especially since it needs an elbow for a 96-98 cobra throttle body.That sounds cool

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Gotta use what’s available though.

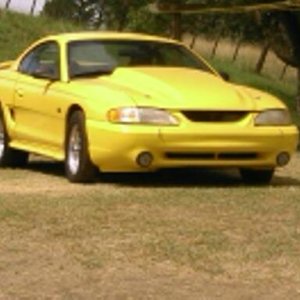

Good news on the paint, it’s about time.

Good news on the paint, it’s about time.

"These are the cam specs. Only guy I could find with the v10 cam core game.. already know your thoughts on him lol mine are kinda in those lines as well"

I can honestly say the guy is on par with business aspects. He meets demands on a timely manner. Takes care of customers. However, you could have called that company directly and had the cams ground for you....eliminating the middleman and his costs.

Cool nonetheless! I just went thru you entire build thread and man you have laid out some time on it!

I also want to encourage you to take all that detailed info, pics, and process you made with the reupholstering your seats and make a seperate thread for the "exterior and interior" forum section. We see if we can get it to be a sticky thread!

I can honestly say the guy is on par with business aspects. He meets demands on a timely manner. Takes care of customers. However, you could have called that company directly and had the cams ground for you....eliminating the middleman and his costs.

Cool nonetheless! I just went thru you entire build thread and man you have laid out some time on it!

I also want to encourage you to take all that detailed info, pics, and process you made with the reupholstering your seats and make a seperate thread for the "exterior and interior" forum section. We see if we can get it to be a sticky thread!

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

I will get to the upholstery sticky in due time. Been making some more progress in other areas."These are the cam specs. Only guy I could find with the v10 cam core game.. already know your thoughts on him lol mine are kinda in those lines as well"

I can honestly say the guy is on par with business aspects. He meets demands on a timely manner. Takes care of customers. However, you could have called that company directly and had the cams ground for you....eliminating the middleman and his costs.

Cool nonetheless! I just went thru you entire build thread and man you have laid out some time on it!

I also want to encourage you to take all that detailed info, pics, and process you made with the reupholstering your seats and make a seperate thread for the "exterior and interior" forum section. We see if we can get it to be a sticky thread!

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

So I started putting green cars engine back together but I may end up trading the turbo setup for a blower setup if 2 of the possible traders get their shit together. So if that happens I would change cams. So I'm leaving the engine together, timed. Followers in but no covers for now.

Decided I would focus on the real meat and potatoes. I installed and torqued all of the main bearings 30 lb ft +90° and the side bolts 22 lb ft + 90° and checked bearing clearances using my dial bore gage.

set the bore gage to the middle of my crank main journal measurements which was 2.6571" and proceeded to check the mains.

They were for the most part in tolerance. Kind of egg shaped, im used to machining in the millionths so this stuff is crazy how out they are to me lol. But nonetheless they were in spec and I compared them to their respective journals and they were in the green.

Next step on main #4 I swapped the oem bolts for arp studs since I needed the pickup tube stud and tossed in a set of arp side bolts on that one journal. Torqued the mains in 3 easy steps to 60 lb ft. Then the 9mm side bolts to 45 lb ft. Then rechecked main #4 with the bore gage seeing if it would warp requiring a line hone.. it actually made it more in spec and rounder. LoL my coworker and I couldn't believe it. Almost tempted to buy a whole set of v8 2v side bolts and main studs. But that would be $150 for nothing. So I'm running it. Next we flipped the block over and ran a hone through it bathing it in honing oil.

Look at that sweet bore... yeahhh baby

Next I gave everything a final wipe down and slathered all of the bearings with Lucas assembly lube as well as the crank play shims. Dropped the crank in and did the final assembly and torque to spec. Spins slowly but smoothly by hand grabbing the snout with my bear hand, the slowness is more than likely due to the honey on the bearings. Checked end play which is right at .007", right in spec.

Thar she blows.. the crank is in.

Isnt she cute!!! Cute like a stomach pump.

Checked the rod journal sizes and documented those as well.

Next time my coworker and I get time we will start checking the rods bearing clearance. If it checks out then it's on to piston rings and rod/piston installation. very... very excited!!

very... very excited!!

Decided I would focus on the real meat and potatoes. I installed and torqued all of the main bearings 30 lb ft +90° and the side bolts 22 lb ft + 90° and checked bearing clearances using my dial bore gage.

set the bore gage to the middle of my crank main journal measurements which was 2.6571" and proceeded to check the mains.

They were for the most part in tolerance. Kind of egg shaped, im used to machining in the millionths so this stuff is crazy how out they are to me lol. But nonetheless they were in spec and I compared them to their respective journals and they were in the green.

Next step on main #4 I swapped the oem bolts for arp studs since I needed the pickup tube stud and tossed in a set of arp side bolts on that one journal. Torqued the mains in 3 easy steps to 60 lb ft. Then the 9mm side bolts to 45 lb ft. Then rechecked main #4 with the bore gage seeing if it would warp requiring a line hone.. it actually made it more in spec and rounder. LoL my coworker and I couldn't believe it. Almost tempted to buy a whole set of v8 2v side bolts and main studs. But that would be $150 for nothing. So I'm running it. Next we flipped the block over and ran a hone through it bathing it in honing oil.

Look at that sweet bore... yeahhh baby

Next I gave everything a final wipe down and slathered all of the bearings with Lucas assembly lube as well as the crank play shims. Dropped the crank in and did the final assembly and torque to spec. Spins slowly but smoothly by hand grabbing the snout with my bear hand, the slowness is more than likely due to the honey on the bearings. Checked end play which is right at .007", right in spec.

Thar she blows.. the crank is in.

Isnt she cute!!! Cute like a stomach pump.

Checked the rod journal sizes and documented those as well.

Next time my coworker and I get time we will start checking the rods bearing clearance. If it checks out then it's on to piston rings and rod/piston installation.

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Another small piece to the puzzle, a guy had these for sale in PA. He was kind enough to sell them to me shipped for $40. I am shocked at how nice they are, theyblook brand new. I hope they work with the convertible flange plates as I do not remember how the convertible ones mount and the car is still at the paint shop.

Wow! Engine going together nice!

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Coming back apart, decided I liked the results of the arp studs so much that I'm doing arp main studs and side bolts in all of the journals. And will recheck the clearance for roundness, reclean and reassemble.Wow! Engine going together nice!

ttocs

Post Whore

I am starting to think you just like to fondle the inside of that v10. I don't think anyone can blame ya for going to studs

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Would fondle it more if I dug into my pockets deeper for forged rods and pistons. Hoping the stock big rod ends with the bearings measure out okay. If the whole thing works out and runs well and is a great success I will consider pulling it and doing forged rods/pistons later on.I am starting to think you just like to fondle the inside of that v10. I don't think anyone can blame ya for going to studs

Well while youre in there, take a sharp tool steel edge deburring scraper and take off the edges of the bearings ends on the inside. Removing the edge slightly, dont go over board. Just enough to prevent the ends from having a mismatch from either different thicknesses or bearing crush. This will reduce wiping the oil. Purchased race oriented bearings are like this. Same goes for rod bearings

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696

Well while youre in there, take a sharp tool steel edge deburring scraper and take off the edges of the bearings ends on the inside. Removing the edge slightly, dont go over board. Just enough to prevent the ends from having a mismatch from either different thicknesses or bearing crush. This will reduce wiping the oil. Purchased race oriented bearings are like this. Same goes for rod bearings

So you're saying use the deburring wand on the outside circumference of the bearings themselves to bevel the edge to reduce the chances of a highspot at the lip.. or some sort of roll over burr when it was being produced.. Should I lightly smoothe the transition of the bevel with some 800 grit following that?

My info was focused on the inside of the bearing ends edge. Again dont go over board

Snorky

Active Member

- Joined

- Feb 10, 2022

- Messages

- 828

- Reaction score

- 696